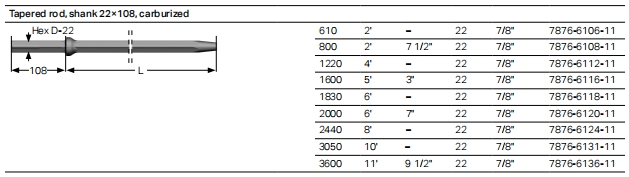

H22 TAPERED TOOLS, 11° TAPER shank 22×108, carburized

2024.10.08Shandike eason

About the characteristics and applications of H22 Tapered Tools and its 11° Taper

- Product Overview

H22 Tapered Tools, especially drill rods and drill bits with 11° Taper, are designed for mining, tunneling, quarrying and similar engineering applications. These tools are usually made of high-quality alloy steel or carbide to ensure excellent wear resistance and durability under harsh working conditions. - Main Features

High wear resistance: H22 Tapered Tools have undergone a special heat treatment process and have extremely high wear resistance, which can maintain a sharp cutting edge during long-term use.

High strength: These tools can withstand high-load drilling operations and are not easy to bend or break.

Precise taper: The 11° taper design allows the drill rod and drill bit to fit tightly, reducing vibration and energy loss during drilling.

Easy to replace: Most H22 Tapered Tools are designed to be easily replaced to save time and cost. - Application areas

Mining: Used to drill ores in mines to extract valuable minerals.

Tunneling: In tunnel engineering, used to drill rock to create a passage.

Quarrying: In a quarry, used to drill and break rock to obtain stone.

Other engineering applications: such as geological exploration, water well drilling, etc.