The DTH (Down-The-Hole) Hammer M30 is a type of drilling equipment commonly used in mining, construction, and water well drilling. It is designed to provide efficient and precise drilling in hard rock formations. Here are some key features and specifications typically associated with the DTH Hammer M30:

Key Features:

Choosing the right conical rods for rock drills is crucial for ensuring efficient drilling and minimizing wear and tear on your equipment. Here are the key factors to consider when selecting conical rods:

1.Rock Type and Hardness

Soft to Medium Rocks: For softer rocks, standard conical rods with moderate hardness and toughness are suitable.

Hard and Abrasive Rocks: For harder or more abrasive rocks, choose rods made from high-strength, wear-resistant materials to withstand the increased stress and wear.

2.Rod Material

High-Quality Steel: Ensure the rods are made from high-quality, heat-treated steel to provide the necessary strength and durability.

Alloy Composition: Look for rods with alloy compositions that enhance hardness and resistance to wear, such as those containing chromium, molybdenum, or nickel.

3.Rod Dimensions

Diameter and Length: Match the rod diameter and length to the specifications of your rock drill and the drilling depth required. Using the wrong dimensions can lead to inefficiency or equipment damage.

Taper Angle: Ensure the taper angle of the conical rod matches the drill bit and drill machine specifications for a secure fit.

4.Thread Type

Compatibility: Check that the thread type (e.g., R32, T38, T45, T51) of the conical rod is compatible with your rock drill and drill bits. Mismatched threads can cause connection failures.

5.Surface Treatment

Hardened Surface: Opt for rods with surface treatments like induction hardening or coatings that improve wear resistance and extend the rod’s lifespan.

Corrosion Resistance: If drilling in wet or corrosive environments, consider rods with anti-corrosion treatments.

6.Manufacturer Reputation

Reliable Brands: Choose rods from reputable manufacturers known for producing high-quality drilling equipment. This ensures better performance and reliability.

Certifications: Look for rods that meet industry standards and certifications for quality and safety.

7.Application-Specific Requirements

Depth of Drilling: For deep drilling, select rods designed to handle the additional stress and torque.

Drilling Method: Consider whether you are using top hammer, down-the-hole (DTH), or other drilling methods, as each may require specific rod characteristics.

8.Cost vs. Performance

Balance: While cost is a factor, prioritize performance and durability. Cheaper rods may save money upfront but can lead to higher costs due to frequent replacements and downtime.

9.Maintenance and Inspection

Regular Checks: Choose rods that are easy to inspect and maintain. Regularly check for signs of wear, cracks, or deformation to prevent failures during operation.

10.Consultation with Experts

Professional Advice: If unsure, consult with drilling equipment specialists or the manufacturer to ensure you select the right conical rods for your specific needs.

By considering these factors, you can choose conical rods that optimize drilling performance, reduce equipment wear, and ensure safety during rock drilling operations.

Common reasons:

Thread wear or damage

Failure to regularly inspect threads, insufficient or excessive tightening torque, resulting in connection failure.

Improper operation

Misalignment of threads during quick fastening or uncoupling, resulting in “wrong fastening” or thread damage.

Material fatigue or quality issues

After long-term use, the drill rod may experience fatigue fracture or the thread processing may not meet the standards.

Complex underground working conditions

Abnormal vibration and sudden torque changes (such as encountering hard formations during drilling) can cause thread loosening.

Emergency response plan:

Immediately stop drilling and cycle

Maintain circulation to prevent sand settling and drill jamming, and confirm the disengagement position.

Salvage operation

Use fishing tools (such as male cones, female cones, and fishing baskets) to grab the fallen fish (trip the drill rod).

Inverted processing

If the salvage fails, extract the drilling tools in sections by reversing them.

Side drilling during well filling (extreme case)

If it cannot be salvaged and affects subsequent operations, cement should be injected to seal the well section and sidetrack around the obstacle.

3、 Comprehensive preventive measures

Strictly inspect tools

Regularly inspect the wear of drill pipe threads and shoulders, and eliminate unqualified drilling tools.

Standardize operational procedures

Tighten according to standard torque, use thread grease, and avoid sudden lifting and releasing.

Optimize drilling parameters

Adjust drilling pressure, rotation speed, and displacement according to the formation to reduce abnormal vibrations.

Real time monitoring

Predict underground risks and make timely adjustments based on changes in parameters such as torque and suspension weight.

Training and Drills

Regularly conduct accident emergency drills to improve team collaboration skills.

4、 Precautions

After the drill is stuck or tripped, it is forbidden to blindly pull or twist it to avoid worsening the accident.

Before salvage operations, sufficient circulation is required to ensure the cleanliness of the wellbore.

If dealing with difficulties, it is necessary to promptly contact professional service companies or technical experts for support.

By standardizing operations, real-time monitoring, and scientific contingency plans, the probability and losses of such accidents can be significantly reduced.

Common reasons:

Unstable wellbore

The collapse of the formation, reduction in diameter, or block falling from the wellbore can cause the drill pipe to get stuck.

Preventive measures: Optimize drilling fluid performance (such as increasing viscosity and plugging), and control wellbore trajectory.

Rock debris accumulation (sand settling and stuck drilling)

Insufficient drilling fluid displacement or prolonged pump shutdown can cause rock debris to deposit and wrap around the drill pipe.

Preventive measures: Maintain the circulation displacement and rock carrying efficiency, and avoid long-term pump shutdown.

Keyway locking drill

Frequent rotation in the directional well forms a keyway, and the drill rod is stuck in the keyway.

Preventive measures: Regularly perform short trips to repair the wellbore and control dogleg deviation.

Adhesive stuck drill (differential pressure stuck drill)

The filtration loss of drilling fluid is large, forming thick mud cake, and the drill pipe and wellbore are adsorbed due to pressure difference.

Preventive measures: Reduce the filtration loss of drilling fluid and use lubricants or extreme pressure grease.

Operational error

Excessive drilling speed can cause pressure stimulation or unreasonable drilling parameters (torque, drilling pressure).

Emergency response plan:

Attempt to move drilling tools

Move the drilling tool up and down (avoiding strong pulling and twisting), while circulating the drilling fluid, gradually increasing the tension to the safe limit.

Adjust the performance of drilling fluid

Inject high lubricity drilling fluid or unblocking agent (such as diesel+surfactant).

Shock release card

Apply high-frequency vibration using a drilling vibrator or ground vibrator.

Soaking acid or unblocking solution

For mud cake adsorption sticking, inject acidic liquid or specialized unblocking agent for soaking.

Inverted or nested milling

If the jam cannot be resolved, the upper drilling tool needs to be inverted and removed, and then the milling cylinder should be inserted to remove the jam.

Frequent fracturing of drill pipes in hard rock formations is a complex technical problem, often caused by multiple factors working together. The following are the main reasons and corresponding preventive measures:

1. Analysis of the cause of fracture1. Material and manufacturing defects-Reason: Insufficient strength of drill pipe material (such as low-quality steel), internal cracks, improper heat treatment, or defects in threaded connections.

-Performance: The fracture surface exhibits brittle fracture characteristics (such as a flat section) or fatigue crack propagation traces.

2. Excessive mechanical stress- Reason :

Hard rock formations have high compressive strength, requiring greater drilling pressure and torque during drilling, resulting in overloading of drill pipes.

The wellbore trajectory is complex (such as excessive dogleg angle), and the drill pipe is subjected to alternating bending stress.

-Performance: Fractures often occur at drill pipe joints or threaded connections.

3. Cumulative fatigue damage- Reason : Severe vibration occurs during hard rock drilling, and the drill rod is subjected to high-frequency alternating loads for a long time, causing fatigue cracks.

Performance: Shell like fatigue lines can be seen on the fracture surface, and cracks gradually propagate inward from the surface.

4. Wear and corrosion- Reason :

Friction between the wellbore and drill pipe causes wear on the outer wall, especially in hard rock where the wear rate is high.

The corrosive components of drilling fluid, such as H ₂ S and CO ₂, accelerate stress corrosion cracking.

Performance: The wall thickness at the fracture site is significantly reduced or there are corrosion pits present.

5. Improper operation- Reason :

Unreasonable settings for drilling pressure and rotational speed parameters (such as blind pressurization in hard rock).

Failure to timely replace worn drill pipes or handle abnormalities in the well (such as forcibly pulling after stuck drilling).

Performance : Sudden rupture accompanied by abnormal operation records.

2. Preventive Measures1. Optimize drill pipe selection and design-Select high-strength alloy steel (such as S135 grade drill pipe) to enhance tensile and fatigue resistance performance.

Use thick walled drill rods or weighted drill rods (such as HEVI-WATE drill rods used for deep well hard rock).

Improve the design of threaded connections (such as double shoulder joints) to reduce stress concentration.

2. Reasonably control drilling parameters-Adjust drilling pressure and rotation speed according to rock type to avoid blind pressure in hard rock (refer to rock drillability classification).

Real time monitoring of torque, vibration, and other parameters using downhole measurement while drilling (MWD) tools to dynamically optimize operations.

3. Reduce vibration and impact-Install shock absorbers or shock absorbers to absorb high-frequency vibration energy.

Use PDC drill bits or impregnated diamond drill bits (for hard rocks) to reduce impact loads.

4. Strengthen maintenance and testing-Regularly conduct non-destructive testing (such as ultrasonic testing, magnetic particle testing), and replace immediately if cracks or excessive wear are found.

Strictly record the usage duration and cumulative fatigue cycle of drill pipes, and implement life management.

5. Optimize wellbore trajectory and drilling fluid performance-Control wellbore curvature (dogleg angle<5 °/30m) to reduce bending stress.

Use high lubricity drilling fluid (such as oil-based mud) to reduce friction coefficient and minimize wear.

6. Operator training-Develop drilling standards for hard rock formations to avoid unauthorized operations such as hard lifting and sudden release.

Train personnel to identify early fault signals (such as sudden torque changes and abnormal pump pressure).

III. Case AnalysisThe key measure to reduce the frequency of drill pipe fracture by 80% in a deep hard rock geothermal well project is:

Adopting S135 grade drill pipe with double shoulder joints to enhance fatigue resistance;

Introduce a downhole vibration monitoring system to dynamically adjust the rotational speed;

Perform magnetic particle testing on the drill pipe every 200 hours of drilling and replace the hidden drill pipe in advance.

SummaryThe fracture of drill pipes in hard rock formations is the result of the synergistic effect of materials, mechanics, and operations. Prevention needs to start from multiple dimensions such as design selection, parameter optimization, detection and maintenance, combined with real-time monitoring and standardized operation, in order to significantly reduce the risk of fracture.

What impact does the heat treatment process of drill pipes have on their performance?

The heat treatment process of drill pipes has a significant impact on their performance, and improper treatment may lead to fracture. The following is a detailed analysis and preventive measures:

1、 The Influence of Heat Treatment Process on Drill Rod Performance

1. Strength and hardness

Quenching: Increases hardness and strength, but excessive quenching can lead to increased brittleness and residual stress.

Tempering: Eliminating quenching stress, balancing strength and toughness. If the tempering temperature is insufficient or the time is too short, the material may retain brittleness.

2. Resilience

Insufficient tempering or too fast cooling rate can reduce impact toughness and easily cause crack propagation.

Tempering brittleness (such as tempering certain steels at 300-500 ℃) can significantly reduce toughness.

3. Residual stress

Uneven cooling or phase transformation during heat treatment can lead to residual stress concentration and become a source of cracks.

4. Uniformity of microstructure

If a mixed structure of martensite and bainite appears, it may lead to local stress concentration and reduce fatigue life.

5. Wear resistance and fatigue resistance

Improper surface treatment (carburizing, nitriding) may result in excessively high surface hardness, mismatch with core toughness, and accelerate fatigue crack initiation.

2、 Measures to avoid fracture caused by improper heat treatment

1. Optimize heat treatment process parameters

Temperature control: precise control of quenching temperature (such as 850-880 ℃ for medium carbon steel) and tempering temperature (depending on material selection, such as 500-600 ℃).

Cooling rate: Use appropriate cooling media (oil quenching, water quenching, or graded cooling) to avoid cracking caused by rapid cooling.

Insulation time: Ensure sufficient transformation of the organization, such as sufficient tempering time to eliminate stress.

2. Material selection and pretreatment

Choose steel with high purity and low impurities (such as low sulfur and phosphorus content) to reduce segregation and inclusions.

Perform normalizing or annealing pretreatment to refine grain size and improve the uniformity of the microstructure after processing.

3. Residual stress management

After quenching, tempering should be carried out in a timely manner, using stress relief annealing (such as 300-400 ℃ insulation and slow cooling).

Shot blasting treatment is applied to key areas (such as threaded connections) to introduce compressive stress to counteract tensile stress.

4. Process monitoring and detection

Real time monitoring of furnace temperature uniformity using thermocouples and infrared thermometers.

Use metallographic analysis and hardness testing (such as Rockwell hardness HRC) to verify the microstructure state.

Non destructive testing (ultrasonic testing, magnetic particle testing) is used to identify microscopic cracks and defects.

5. Post treatment and surface strengthening

Perform carburizing, nitriding, or coating treatment on the surface to improve wear resistance while avoiding excessive hardening.

To avoid local overheating during subsequent processing (such as grinding), low-temperature processing technology should be used if necessary.

6. Standardization and Training

Strictly implement heat treatment process standards (such as API Spec 5DP requirements for drill rods).

Regularly train operators to ensure equipment maintenance and process stability.

3、 Typical Case Analysis

Case 1: Due to the rapid quenching and cooling rate of a certain drill rod, coarse martensite was formed on the surface, and the residual stress inside was too high, resulting in brittle fracture under downhole torsional load. Improvement measures: Switch to oil quenching and extend tempering time.

Case 2: Insufficient tempering temperature (only 400 ℃) did not completely eliminate quenching stress, and the drill rod cracked from the root of the thread under fatigue load. Solution: Adjust the tempering temperature to 550 ℃ and extend the holding time.

4、 Summary

The heat treatment process directly affects the strength, toughness, and fatigue life of drill rods. By precisely controlling process parameters, optimizing material selection, strengthening detection and post-treatment, the risk of fracture can be significantly reduced. Continuously improving processes based on industry standards (such as API, ISO) and actual working conditions is the key to ensuring the reliability of drill pipes.

The main purpose of carburizing the drill rod of a rock drill during the production process is to optimize the balance between the surface and core properties of the material, and improve its durability and reliability under harsh working conditions. The following is the specific purpose and technical analysis of carburizing treatment:

-Mechanism: Carbonization is achieved by infiltrating carbon elements into the surface of the drill rod, forming a high carbon layer (usually with a carbon content of 0.8% -1.2%), followed by quenching and low-temperature tempering, resulting in the formation of a high hardness martensitic structure on the surface.

– Effect : The surface hardness can reach HRC 58-64, significantly improving the wear resistance, addressing wear problems caused by friction with rocks, and extending the life of drill pipes.

-Material selection: The drilling rod matrix is usually made of low carbon steel (such as 20CrMnTi), which has a low carbon content in the core after carburizing (about 0.1% -0.3%), low hardenability, and retains a tough structure (such as ferrite+pearlite).

-Performance Balance : The high toughness core can absorb impact energy, prevent brittle fracture of drill rods during high-frequency impact operations, and adapt to the high dynamic load conditions of rock drills.

-Process influence : The volume of the carburized layer expands during quenching, forming compressive stress on the surface, offsetting the tensile stress during operation, and delaying crack initiation. – Fatigue resistance improvement : Surface compressive stress state can increase the bending fatigue strength of drill pipes (by about 30% -50%), reducing fatigue failure caused by cyclic stress.

-Cost effectiveness: Compared to overall high alloy steel, carburizing treatment reduces material costs while ensuring performance, making it suitable for mass production.

-Depth control: The depth of the carburized layer is usually designed to be 0.8-1.5mm (adjusted according to the diameter of the drill pipe), taking into account wear resistance requirements and avoiding excessive thickness of the brittle layer.

-Improved anti bite performance: The high hardness surface reduces adhesive wear when in contact with rocks.

-Dimensional stability: Low temperature tempering (180-220 ℃) reduces deformation while maintaining hardness, ensuring the geometric accuracy of the drill rod.

-Process control: Accurate control of carburizing temperature (900-930 ℃), time, and carbon potential is required to avoid grain coarsening or excessive carburizing leading to brittleness.

-Subsequent processing: Grinding is required after carburizing to eliminate the oxide layer and ensure assembly accuracy.

Through carburizing treatment, the drill rod of the rock drill achieves a gradient performance of “external hardness and internal toughness”, and its comprehensive service life can be increased by 2-3 times compared to untreated drill rods. It is a key process that balances performance and economy.

Dear Customer,

We will participate in bauma CHINA 2024 during November 26-29 at Shanghai New International Expo Centre (SNlEC). We will display our new products and present advanced solutionson the leading trade fair for construction machinery, building material machines, mining machines and construction vehicles. We cordially invite you to attend the grand event and visit our booth.

Welcome to our BOOTH:NO.E5.861

Top hammer thread drilling rod 28mm (diameter 28mm)

1、 Product Overview

Name: Top Hammer Thread Drilling Rod 28mm

Diameter: 28mm

Type: Top Hammer Threaded Drill Rod

Purpose: Mainly used in engineering fields such as mining, rock drilling, tunnel excavation, etc.

2、 Product Features

High strength: The drill rod is made of high-quality alloy steel, which has high strength and wear resistance, and can withstand large drilling pressure and torque.

High precision: The threaded part adopts precision machining technology to ensure a tight and reliable connection with the drilling rig, reducing shaking and vibration during the drilling process.

Long service life: After special heat treatment process, the service life of the drill rod is significantly improved, reducing the frequency and cost of replacement.

3、 Purchase advice

Choose suppliers with good reputation: When purchasing, priority should be given to suppliers with good reputation and high-quality reputation to ensure product quality and after-sales service.

Understand product details: Before purchasing, it is necessary to thoroughly understand the specifications, materials, performance, and other parameters of the product to ensure that it meets one’s own usage needs.

4、 Application Fields

Comparing prices and services: When purchasing, you can compare prices and services from different suppliers and choose products with high cost-effectiveness.

Pay attention to transportation and installation: After purchasing, pay attention to the transportation and installation process of the product to ensure that it can arrive safely and accurately at the site of use, and be installed and used correctly.

The use of the Top Hammer Thread Drilling rod 28mm (diameter 28mm) is mainly concentrated in mining, rock drilling, tunnel excavation, and other engineering fields that require deep hole drilling. Here are its specific uses:

Mining: In mines, drill rods are used to extract mineral resources such as ores and rocks. Through drilling, the distribution and reserves of ore can be determined, providing data support for subsequent mining.

Rock drilling: In geological exploration, geotechnical engineering and other fields, drill rods are used to drill rocks to obtain geological information underground. This helps to understand underground structures, rock distribution, hydrogeological conditions, etc., providing a basis for engineering design and construction.

Tunnel excavation: In tunnel engineering, drill rods are used for excavation operations. Through drilling, rocks can be broken and tunnels can be excavated, providing a pathway for subsequent construction work.

Other engineering fields: In addition to the above-mentioned fields, drill rods are also widely used in engineering fields that require deep hole drilling, such as water well drilling, geothermal resource development, and anchoring engineering.

When in use, the drill rod is connected to the drilling rig through threads, and is pushed into the ground for drilling by the top hammer of the drilling rig. The diameter, length, and material parameters of the drill rod will be selected based on specific drilling requirements and geological conditions.

5、 Market price

The price of the Top Hammer Thread Drilling rod 28mm (diameter 28mm) may fluctuate due to various factors such as market supply, product quality, production costs, purchase quantity, and regional differences.

1、 Price Range

Generally speaking, the price of the Top Hammer Thread Drilling rod 28mm may vary depending on different suppliers, brands, and quality levels.

In the market, entry-level products with relatively low prices can be found, which may be manufactured using common materials and processes, suitable for some drilling operations that do not require high performance.

At the same time, there are also high-end products with higher prices, which are usually made of high-quality alloy steel, processed with precision machining and special heat treatment processes, and have higher strength, wear resistance, and service life, suitable for drilling operations with high performance requirements.

2、 Price influencing factors

Market supply situation: The supply of drill pipes in the market will directly affect their prices. If there is sufficient supply of drill pipes in the market, the price may be relatively low; If supply is tight, prices may rise.

Product quality: Product quality is an important factor affecting price. High quality products are usually manufactured using better materials and processes, with higher performance and longer service life, so the price will also be relatively high.

Production cost: Production cost includes raw material cost, processing cost, transportation cost, etc. If production costs increase, suppliers may raise product prices to maintain profit levels.

Purchase quantity: The purchase quantity is also a factor that affects the price. Generally speaking, the larger the purchase quantity, the supplier may offer a certain discount or discount.

Regional differences: Market demand, consumption levels, and logistics transportation costs in different regions can also affect the price of drill pipes.

3、 Price advice

Consulting suppliers: directly contact suppliers or manufacturers to obtain the latest product quotations and discount information.

Compare different suppliers: Compare product quotes and quality from different suppliers in the market, and choose products with higher cost-effectiveness.

Follow market trends: Pay attention to industry developments and market price trends in order to make purchases at the appropriate time.

In summary, the price of Top hammer thread Drilling rod 28mm will be influenced by various factors, and the specific price needs to be determined based on market demand, product quality, production costs, and other factors. When making a purchase, it is recommended to consult multiple suppliers and compare the prices and quality of different products to choose the one with higher cost-effectiveness.

Due to the development of China’s mining industry and the increasing scale of transportation infrastructure construction, as well as the government led requirements for mechanization, automation, and intelligent unmanned construction and mining, the drilling tool market has developed rapidly. It is said that there are dozens of manufacturers with a market size of billions of yuan. But there is still a lot of room for improvement in the performance of domestic brand products.

Today, let’s talk about our experience with the failure of drill rods on rock drilling rigs.

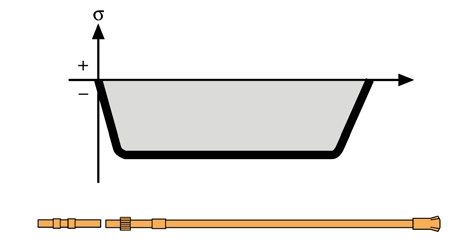

As the drill rod of the excavation trolley, it is the conductor that transfers the impact energy of the rock drill to the rock. Its working form is shown in the figure above. Regardless of the specifications, there are mainly several failure modes, namely normal wear. In addition, one is the breakage of the drill rod, and the other is the deformation of the connecting thread wear. Thread wear and deformation are common, while fractures are relatively rare, but the fracture points are almost always located about 50 centimeters away from the thread sleeve.

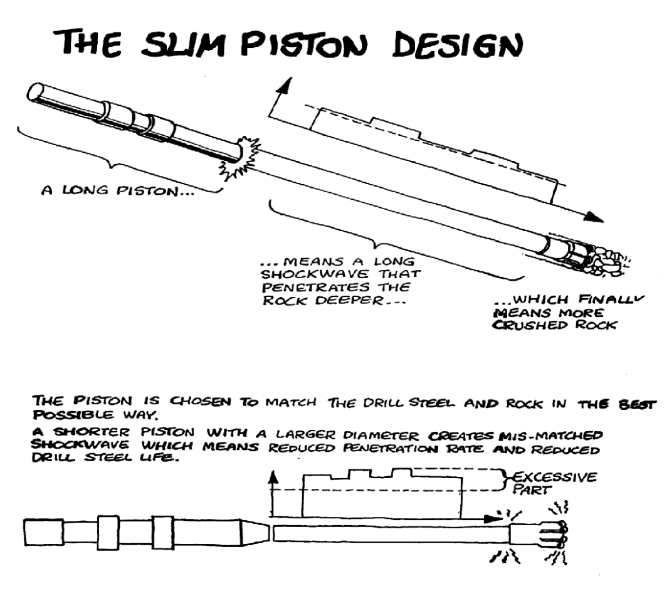

This situation is actually very consistent with the theory of energy transfer fluctuations in rock drills. When the impact piston strikes the drill tail, the kinetic energy of the impact piston is converted into stress waves, which are transmitted to the bottom of the hole through the drill rod and drill bit. In order to achieve optimal drilling economy, the entire system from the rock drill to the drilling tool to the rock must be coordinated with each other. According to the stress wave theory, stress waves are rectangular in shape, with the length of the rectangular wave being twice the length of the piston. The height of the rectangular wave depends on the velocity of the piston at the moment of impact, as well as the relationship between the cross-sectional area of the impact piston and the cross-sectional area of the drill rod, as shown in the figure. The energy generated by the impact of the rock drill piston is transmitted in the form of waves through the drill rod tail, and the drill rod breaks the rock. If you have hit a large hammer, held a drill rod, or chiseled a nail, you can feel the slight expansion of the drill rod with your palm or fingers, and have a sensory experience. According to this theory, at any given impact pressure, the stress wave amplitude in the drill pipe, i.e. the stress value, will become higher due to the reduction in the cross-section of the drill pipe. In order to achieve a longer service life for the drill tail and drill rod, it is important to ensure that the working pressure matches the cross-sectional size of the drilling tool at all times. Atlas Copco’s rock drills all adopt the concept of slender piston, and hope that the diameter of the drill bit tail and the drill rod match with it and are uniform without change, so that the peak value of the energy wave is uniform, which can not only achieve high transmission efficiency, but also improve the life of the drilling tool. This is also why Atlas rock drill is more efficient than other brands.

However, in reality, whether it is a drill tail or a drill rod, due to functional and processing requirements, its structural shape is difficult to fully meet the condition of no change in diameter. From the figure, we can see that in excavation and rock drilling, whether using an integrated fast drill rod or a connecting sleeve, the connection thread between the drill rod tail and the drill rod is the place where the amplitude of the shock wave changes the most, that is, where the shock wave peak will be generated; The accuracy of thread machining, the matching degree of mutual cooperation, and even the deflection changes during the working process of the drill pipe have the greatest impact on this part, which is why drill pipe failures occur more often in this area. So, if drilling tool manufacturers can make efforts in this area, there is still a lot of work to be done.

But in reality, I believe that only improvement can be made. In a sense, this problem is unsolvable for horizontal excavation and rock drilling.

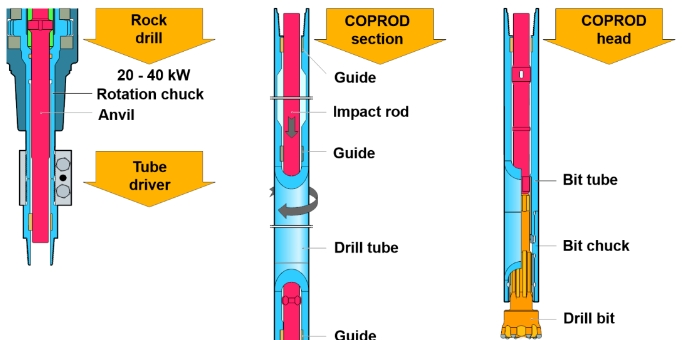

In open-pit rock drilling, down the hole hammers are now more commonly used, and since the drill pipe does not withstand impact, there is no such problem. Atlas skillfully used a kind of drill tool called COPROD for top hammer drilling. As shown in the figure, the outer casing does not bear impact, and the internal impact rod does not use threaded connection, but uses lap joint, so the diameter will not change, and the waveform will not have peak changes. The drilling speed and the life of the drilling tool are both very long, but basically it is only suitable for vertical drilling.

Product Introduction: Drifter Rod (Threaded Drill Rod, Hydraulic Drill Rod, Heavy duty Drill Rod)

Drifter rod, also known as threaded drill rod, hydraulic drill rod or heavy-duty drill rod, is an efficient tool designed specifically for breaking rocks. This unique hollow hexagonal rod is equipped with precision connecting threads at both ends, allowing it to effectively transmit the impact force and torque of hydraulic rock drills, easily handling various hard rock layers.

1、 Product Definition and Functionality

The core function of the Drifter rod is its ability to efficiently transmit power, converting the powerful energy of hydraulic rock drills into the actual effect of breaking rocks. Its hollow hexagonal design not only reduces weight, but also enhances overall strength and stability, ensuring stable operation in various harsh mining and excavation environments.

2、 Main specifications

In order to meet the needs of different customers, the Drifter rod offers a variety of thread forms to choose from, including R25, R28, R32, T38, T45, T51, ST58, GT60, etc. These different thread forms can be adapted to various models of hydraulic rock drills, ensuring the best matching effect and the highest work efficiency.

3、 Type

Drifter rods are mainly divided into two types: quick drilling rods (MF rods) and extended rods (MM rods). Fast drilling rods are known for their ability to quickly penetrate rocks and are suitable for work scenarios that require efficient excavation; Extending the drill rod expands the operating range by increasing its length, suitable for deep or difficult to access rock layers.

4、 Application Fields

With its strong crushing ability and adaptability, Drifter rods have been widely used in construction projects such as open-pit mining, underground mining, tunnel excavation, and quarrying. It can not only improve work efficiency, but also reduce the labor intensity of workers, making it an indispensable and important tool in these fields.

5、 Selection factors

When choosing a Drifter rod, customers need to consider multiple factors to ensure that they select the product that best suits their needs. These factors include application scenarios, specifications, materials (such as high-strength alloy steel to improve wear resistance and strength), load and torque requirements, manufacturer reputation, and budget.

6、 Recommended brand

Among numerous Drifter rod brands, we strongly recommend the SHANDIKE brand. SHANDIKE always adheres to the principle of quality first and technological leadership, and is committed to providing customers with the highest quality products and services. The Drifter rods produced by it not only have excellent performance, but also reasonable prices, making them an ideal choice for customers. In addition, SHANDIKE also provides global export and professional after-sales service to ensure that customers receive comprehensive support during use.

7、 Contact Information

If you are interested in SHANDIKE brand Drifter rods or need more information, please feel free to contact us at any time.

Company Name: Luoyang Shandike Mechanical Equipment Co., Ltd

Email: [email protected]

Phone:+86 19937978951

WhatsApp:+86 19937978951

Office Address: Room 2311, Nanchang Road, Luoyang City, China

Factory Address: No.1 Lihe Avenue, Yiyang County, Luoyang City, China

To maximize the service life of your down-the-hole drill bits, consider implementing these comprehensive strategies:

Material Selection and Quality Assurance:

High-Quality Materials: Select drill bits crafted from superior materials known for their exceptional wear resistance, high-temperature tolerance, and durability. High-grade alloys and specialized composites often yield superior performance.

Coatings: Opt for drill bits with premium coatings that bolster wear resistance, corrosion resistance, and thermal stability, thereby prolonging their lifespan.

Design and Geometry Optimization:

Optimal Design: Ensure that the drill bit boasts a well-thought-out geometry tailored to the specific drilling application. A thoughtfully designed drill bit head and cutting edges can mitigate wear and enhance efficiency.

Geometry Maintenance: Regularly inspect and maintain the drill bit’s geometry. Sharpen worn-out edges or replace them as needed to maintain peak cutting performance.

Operating Parameters and Conditions:

Reasonable Operating Parameters: Fine-tune drilling parameters such as spindle speed, feed rate, and drilling pressure to optimize the drilling process. Avoid excessively high speeds and pressures that can lead to premature wear.

Cooling and Lubrication: Employ cooling lubricants to keep the drilling area cool, minimize friction, and ward off thermal wear. This aids in preserving the drill bit’s sharpness and extends its life.

Drilling Environment: Be mindful of the material being drilled and its properties, including hardness and abrasiveness. Choose the appropriate drill bit and adjust drilling parameters accordingly to align with the material’s characteristics.

Maintenance and Management:

Regular Inspections: Conduct thorough inspections of the drill bit for signs of wear, cracks, or damage. Promptly replace worn-out bits to forestall further degradation and ensure efficient drilling.

Storage Conditions: Store drill bits in a dry, rust-free environment to prevent corrosion and deterioration.

Professional Training: Provide operators with training on the proper use and maintenance of drill bits. Proper handling and operation can drastically reduce abnormal wear and extend the bit’s life.

Specific Considerations for Diamond Bits:

For diamond bits, additional factors to consider include:

Diamond Quality: The grade, size, and concentration of diamonds in the bit impact its lifespan. Choose bits with diamonds that are well-suited for the intended drilling application.

Matrix Composition: The matrix material and its properties are crucial in supporting the diamonds and ensuring they are effectively exposed for cutting. Optimize the matrix composition to match the drilling conditions and material being drilled.

Manufacturing Process: The manufacturing process, including sintering and brazing techniques, can affect the bit’s durability. Ensure high-quality manufacturing to minimize defects and enhance performance.

Pre-Shipping Checklist:

Ensure the drill bit does not come into contact with the metal surface, especially avoiding the bottom of the alloy buttons touching each other.

Carefully inspect the drill bit before shipping and jot down the drill bit number and serial number for future reference.

Foot Valve Maintenance:

Verify the correct installation of the foot valve and its proper exposed height. Ensure the foot valve is intact.

Inspect for damaged and corroded impact ends, typically due to inadequate lubrication. A cracked impact tip often stems from severe wear of the piston, circlip, or bottom bushing.

DTH Button Bit Maintenance:

Drill Bit Head Maintenance:

In highly abrasive formations, the drill body wears down faster than the alloy buttons, a phenomenon known as “drill erosion.” To minimize alloy button breakage, grind them so they are no higher than 9 mm from the drill bit surface.

Control the depth of the chip removal groove due to abrasiveness and wear on the body caused by high drilling speeds. Frequently regrind the flutes to ensure effective debris removal.

Severe erosion and the force of the piston hitting the drill bit can cause alloy buttons to fall off, known as “button loss.” This can occur even with minor erosion. When drilling into soft formations, frequently remove the drill bit for cleaning to maintain constant contact between the drill bit surface and the bottom rock.

Increasing the rotation speed does not necessarily boost the penetration rate but rather increases the wear frequency, particularly in abrasive layers. Under abrasive conditions, control the wear frequency based on the required drilling depth.

A flattened surface button typically indicates a lack of flow energy from the hammer or insufficient torque. Inspect the drill bit for minute cracks at the bottom. Failure to address this condition can lead to surface chipping and ultimately complete failure of the bottom.

1、 Product Overview and Applications

The 6 “QL60 DTH (Down The Hole) Hammer is a downhole impact hammer designed specifically for mining and water well drilling in South Africa and other regions. With its advanced technology and high-quality materials, the hammer exhibits excellent durability and performance, suitable for rock formations of various hardness, and can efficiently break rocks, significantly improving drilling efficiency.

The 6.5” HP QL60 Hammer is a Rock Hog Drilling Products Brand 6” Class QL60 Shank Hammer. The 6.5” HP QL60 Hammer is a Model-65 Hi-Performance, Heavy duty model for QL6 shank bit. The drill pipe connection-3-1/2 REG API pin up type configuration.

This hammer has an OD of 5.90” (150mm) and discard OD size is 5.43”(135.6mm). This hammer has slightly larger internals than the RH61QHD1HP. This allows for faster penetration rates.

In South Africa, this DTH Hammer is widely used in the following scenarios:

Mining: As a globally renowned mineral rich country, QL60 DTH Hammer plays a crucial role in the mining process in South Africa, used to break rocks and improve the overall efficiency of mining operations.

Water well drilling: In some areas of South Africa where water resources are scarce, water well drilling has become an important means of obtaining groundwater resources. QL60 DTH Hammer can quickly penetrate rock layers and achieve ideal drilling depths, providing stable water resources for local residents.

Geological exploration: QL60 DTH Hammer also plays an indispensable role in geological exploration work in South Africa, used to obtain underground rock samples and provide valuable data support for geological research.

2、 Product Features

Efficient drilling: QL60 DTH Hammer has won wide acclaim in drilling operations in South Africa for its powerful impact and efficient drilling speed.

Strong durability: Made of high-quality stainless steel and other high-strength materials, QL60 DTH Hammer still performs well in the harsh drilling environment of South Africa, extending the product’s service life.

Wide applicability: QL60 DTH Hammer is not only suitable for mining and water well drilling, but also widely used in various fields such as geological exploration, meeting the drilling needs of different customers in South Africa.

Easy to maintain: The reasonable design makes the QL60 DTH Hammer easy to disassemble and assemble, making it convenient for South African users to carry out daily maintenance and upkeep work.

3、 Price and purchasing advice

In South Africa, the price of QL60 DTH Hammer varies depending on factors such as supplier, order quantity, and delivery conditions. Generally speaking, the price range of these products is between hundreds and thousands of dollars. In order to obtain more favorable prices and reliable delivery guarantees, it is recommended that South African users follow the following advice when purchasing:

Choose a well-known supplier: When purchasing, choose a supplier with good reputation and strong technical strength to ensure product quality and after-sales service. In South Africa, some well-known drilling equipment suppliers may offer sales and services for QL60 DTH Hammer.

Understanding product specifications: Before purchasing, it is important to have a detailed understanding of the product’s specifications, performance, and usage conditions to ensure that the selected product meets actual needs. Especially pay attention to key parameters such as the outer diameter, discarded outer diameter, and internal components of the product.

Negotiating prices and delivery terms: When negotiating prices with suppliers, factors such as order quantity and delivery time should be fully considered to obtain more favorable prices and more reliable delivery guarantees. At the same time, it is also necessary to understand the supplier’s after-sales service policy to ensure timely technical support and maintenance services during use.

In summary, the 6 “QL60 DTH Hammer has broad application prospects in the fields of mining, water well drilling, and geological exploration in South Africa. South African users should choose well-known suppliers when purchasing, understand product specifications, and negotiate prices and delivery terms with suppliers to ensure the purchase of cost-effective products.

QL60 High Air Pressure DTH Hammer With Foot Valve Specification:

| Items | Replacement Parts |

| 1 | Top sub |

| 2 | O-ring of top sub |

| 3 | Breakout Ring |

| 4 | Check Valve |

| 5 | Spring |

| 6 | Compression Buffer |

| 7 | Air Distributor |

| 8 | Internal cylinder |

| 9 | Piston |

| 10 | External cylinder |

| 11 | Guide sleeve |

| 12 | O-ring of stop ring |

| 13 | Stop ring |

| 14 | Breakout ring |

| 15 | Drive chunk |

| 16 | Drill bit |

| Drilling Diameter(mm) | Hammer Length Without Bit(mm) | External Diameter(mm) | Weight Without Bit(kg) | ||||

| φ155-φ190 | 1212 | 142mm, 144mm,146mm, 148mm | 95 | ||||

| Working Pressure(Mpa) | Air Consumption(m³/min) | ||||||

| 1.5-2.5 Mpa | 1.0Mpa: 10 m³/min | 1.8Mpa: 20 m³/min | 2.4Mpa: 28.5 m³/min | ||||

| Impact rate at 17 bar | Recommended Rotation Speed | Connection Rod Thread | Bit Shank | ||||

| 23HZ | 20-30 r/min. | API 3 1/2” Reg | QL60 | ||||

T45 89mm button bits, also known as T45 specification button bits with a diameter of 89mm, are a drilling tool designed specifically for high efficiency and wear resistance.

1、 Main features

Efficient and wear-resistant: This drill bit is made of durable hard alloy material, ensuring a long service life and reliable operational performance, especially suitable for demanding construction and mining applications.

Wide applicability: This drill bit is not only suitable for construction projects, but also widely used in the energy and mining industries, meeting the diverse needs of different users.

Multiple shapes and designs: T45 89mm button bits are typically equipped with different types of buttons such as spherical, ballistic, and flat or descending center designs to accommodate different drilling conditions and rock types.

2、 Product specifications

Diameter: 89 millimeters (approximately 3.5 inches)

Type: Button Bit

Specification and model: T45

Button specifications: may include buttons of different sizes, such as 8 × 13mm, 4 × 12mm, etc., depending on product design and manufacturer.

Number of flushing holes: Depending on product design and application requirements, different numbers of flushing holes may be equipped.

3、 Application scenarios

T45 89mm button bits are mainly used for hard rock drilling operations, including but not limited to the following scenarios:

Mining operation: Used for drilling ore and rock samples during the mining process, or conducting drilling operations before blasting.

Construction engineering: In foundation engineering, tunnel engineering, and underground engineering, it is used to drill holes for underground passages, basements, and subway tunnels.

Energy industry: used for drilling boreholes and conducting geological exploration in the exploration and development of oil, natural gas, and geothermal energy.

4、 Product advantages

Improving drilling efficiency: Due to the use of wear-resistant materials and optimized design, T45 89mm button bits can significantly improve drilling efficiency and reduce drilling costs.

Extended service life: The use of hard alloy materials gives the drill bit a longer service life, reducing the frequency of drill bit replacement and downtime.

Enhancing safety: Optimized drill bits and stable drilling performance can help reduce safety risks during the drilling process.

5、 Manufacturers and suppliers

T45 89mm button bits are produced by professional manufacturers such as SHANDIKE. These manufacturers usually have rich production experience and advanced technological strength, and can provide high-quality products and excellent after-sales service.

In summary, T45 89mm button bits are an efficient, wear-resistant, and widely applicable drilling tool for the construction and mining industries. Its superior performance and diverse design enable it to meet the diverse needs of different users, and play an important role in improving drilling efficiency and reducing costs.

Specification Confirmation:

Firstly, ascertain the taper. The taper plays a crucial role in ensuring the stability of the connection and the efficiency of torque transmission between the drill rod and the drill bit. Common tapers utilized are 7 degrees, 11 degrees, and 12 degrees. Secondly, determine the appropriate diameter. For softer rocks, diameters ranging from Φ19 to Φ22 mm are suitable. Medium-hard rocks require diameters between Φ25 and Φ28 mm, while hard rocks necessitate diameters of Φ32 mm or larger. Lastly, establish the necessary length of the drill rod, which should align with the drilling depth and construction specifications. Our offerings include short drill rods (400-800 mm), medium-long drill rods (1000-1600 mm), and long drill rods (2000 mm and above).

Matching Rock Drill Specifications:

Ensure that the connection end specifications of the drill rod are compatible with the interface of the rock drill machine. Common connection end specifications include 22 x 108 mm and 25 x 108 mm.

Importance of Tapered Rock Drill Rods:

Tapered rock drill rods are indispensable tools in rock drilling operations. They boast high strength, wear resistance, reliable connections, and efficient operation. These rods are extensively utilized in a variety of drilling and rock crushing applications.

Hexagonal Hollow Steel H22/H25 Tapered Drill Rods are precision tools meticulously crafted for rock drilling applications.

1. Product Highlights

Material Composition & Design:

Crafted primarily from premium steel grades like 55SiMnMo, these rods guarantee robust strength and exceptional wear resistance. Their innovative hexagonal hollow design not only reduces overall weight but also bolsters torsional rigidity and operational stability.

Specifications & Dimensions:

Available in two primary specifications, H22 and H25, these rods cater to a wide array of drilling requirements, accommodating various aperture sizes and drilling depths. Lengths can be tailored to customer specifications, typically ranging from 1m to 5m. Taper angles, such as 7° and 11°, are tailored to suit diverse drilling methodologies.

Versatile Applications:

These rods excel in mining, tunnel excavation, geological exploration, and more. They are particularly adept at shallow hole drilling operations with pneumatic or hydraulic drilling machines.

2. Outstanding Performance Benefits

Strength & Durability:

Through rigorous heat treatment and advanced manufacturing processes, the hardness and wear resistance of these drill rods are significantly enhanced, prolonging their lifespan. They maintain consistent performance even in the most arduous drilling conditions.

Robust Connectivity:

Equipped with threading or other advanced connection methods, these rods ensure seamless integration during drilling, fostering stability and operational continuity. Their compatibility with a range of drilling rigs and bits elevates drilling efficiency.

User-Friendly Design:

The ergonomic design of these rods ensures they are lightweight, portable, and straightforward to install. Operators can effortlessly manage the rod’s direction and penetration depth during drilling operations.

3. Market Demand & Future Prospects

Rising Demand:

The burgeoning mining and tunnel excavation industries are driving up the demand for high-quality drill rods. In particular, complex geological formations necessitate robust, wear-resistant, and highly connectable rods.

Progressive Enhancements:

As technology advances and manufacturing processes refine, the performance of hexagonal hollow steel H22/H25 conical drill rods will continue to improve. They are poised to become even more ubiquitous in diverse drilling applications, propelling industry growth.

4. Purchase Considerations

Trusted Manufacturers:

When acquiring these rods, prioritize manufacturers with proven credentials and a solid reputation. This ensures you receive superior product quality and dependable after-sales support.

Informed Decisions:

Before making a purchase, thoroughly familiarize yourself with the rod’s specifications, dimensions, performance characteristics, and other pertinent details. This will empower you to select the ideal rod for your needs.

Price & Value:

While price is a crucial consideration, it should not be the sole determinant. Evaluate the rod’s cost-effectiveness, balancing quality, performance, and price to make an informed decision.

In conclusion, the hexagonal hollow steel H22/H25 conical drill rod is a formidable drilling tool, characterized by its superior performance, ease of use, and versatility across mining, tunnel excavation, and other industries. When acquiring these rods, choose a reputable manufacturer, understand their capabilities, and strike the right balance between price and value.

Specification

| Shank size | Length in mm | Length in feet |

| 22×108 | 610 | 2 |

| 22×108 | 1220 | 4 |

| 22×108 | 1830 | 6 |

| 22×108 | 1980 | 6-1/2 |

| 22×108 | 2440 | 8 |

| 22×108 | 3050 | 10 |

| 22×108 | 3660 | 12 |

| 22×108 | 5485 | 18 |

| 22×108 | 6400 | 21 |

| 22×108 | 7315 | 24 |

| 25×108 | 1500 | 4,9 |

| 25×108 | 1830 | 6 |

| 25×108 | 2000 | 6-1/2 |

| 25×108 | 2200 | 7,2 |

| 25×108 | 3050 | 10 |

January 11, 2024

January 11, 2024