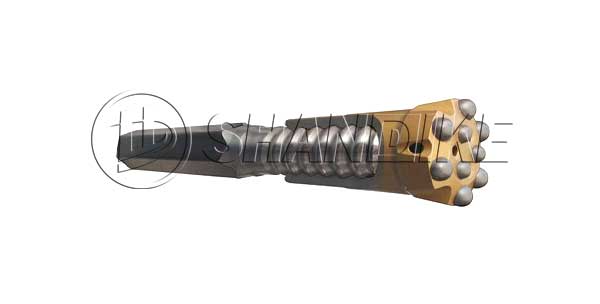

QL80 DTH Spherical (Ballistic) Button Bits

1. Overview

QL80 DTH Spherical (Ballistic) Button Bits are specifically designed for pneumatic impact drilling (DTH) rigs. They are suitable for drilling operations in various hard rock and abrasive formations. The unique spherical (or ballistic, depending on the model) tooth setting design enhances the wear resistance and drilling efficiency of the drill bit.

2. Main Features

Strong Wear Resistance: Made of high-quality alloy steel material and subjected to special heat treatment, these bits offer improved wear resistance and service life.

High Drilling Efficiency: The spherical or ballistic toothed design effectively crushes rocks and increases drilling speed.

Strong Adaptability: Suitable for drilling into various hard rocks and abrasive formations, such as granite, marble, and basalt.

Easy to Replace: Designed with standard specifications, these bits are compatible with various DTH drilling machines, making them easy to replace and maintain.

3. Technical Parameters

Model: QL80

Diameter: Typically 203mm (8 inches), but specific dimensions may vary based on the manufacturer and application.

Gear Shape: Spherical or ballistic (tapered shape similar to a bullet or missile tip).

Drill Face Shape: Flat, concave, or convex, selected according to specific needs.

Work Pressure: Usually within the range of 8-30 bar, depending on the drilling rig and formation conditions.

Packaging: Wooden crates are used for packaging to ensure safe transportation.

4. Application Fields

QL80 DTH Spherical (Ballistic) Button Bits are widely used in mining, water well drilling, geological exploration, building foundation construction, and other fields. Their superior performance and wear resistance are particularly recognized in projects requiring drilling into hard rock and abrasive formations.

5. Supplier and Purchasing Suggestions

Multiple professional manufacturers, both domestically and internationally, produce QL80 DTH Spherical (Ballistic) Button Bits, such as Luoyang Shandike Mechanical Equipment Co., Ltd. in China. When purchasing, it is recommended to choose the appropriate model and specifications based on specific needs and budget. Additionally, select suppliers with a good reputation and after-sales service to ensure product quality and support.

6. Working Principle

During operation, the pressure regulating mechanism pushes the drill tool forward, keeping the drill bit in contact with the rock at the bottom of the hole. The DTH hammer at the front end of the drill rod, under the action of air pressure, continuously impacts the drill bit. The bit obtains impact energy and sinks into the bottom of the hole, generating an impact force that crushes the rock.

7. Popular Models

The most popular specifications include:

QL80-203mm/8’’, 819+1219

QL80-216mm/8 1/2’’, 1019+619+8*19

QL80-222mm/8 3/4’’, 1219+619+8*19

QL80-254mm/10’’, 1019+619+8*19

The exact bit size can vary depending on specific drilling requirements. The buttons can be spherical or ballistic, chosen based on the rock formation.

8. Function of Splines Designs

Processing strictly in accordance with design requirements to ensure proper clearance and uniformity of splines.

Carburizing and quenching of the surface to increase surface hardness and resistance to plastic deformation and impact fatigue.

Reducing surface roughness and improving contact accuracy.

Increasing the cross-sectional area of the splines to enhance the strength of the drill bit.

Summary

QL80 DTH Spherical (Ballistic) Button Bits are a high-performance and wear-resistant pneumatic impact drill bit suitable for various hard rock and abrasive formations. When selecting and using these bits, reasonable choices should be made based on specific needs and conditions. For faster penetration in softer rock formations, ballistic button bits may be preferred, while spherical button bits may be more suitable for harder rock or longer durability requirements.

Drifting and tunneling R25 drill rods are used in underground mining and construction projects. They are made of high-strength steel and have a hollow core and a threaded connection system on both ends.

Drilling Technique:

R25 drill rods are used with a variety of drilling techniques, including hand-held rock drills, pneumatic rock drills, and electric rock drills. They are suitable for use in drilling both soft and hard rock formations.

Size and Length:

The standard diameter of an R25 drill rod is 25mm (about 1 inch). The length of the rods can vary depending on the specific drilling application, but they are typically available in lengths ranging from 1 to 6 meters (3 to 20 feet). Extension rods can also be used to extend the reach of the drill bit and can be threaded together with other R25 drill rods to create a longer drill string.

Thread Type and Coupling:

R25 drill rods have a specific thread type and coupling system that is used in conjunction with other components of the drilling system. They are threaded on both ends and use an R25 thread connection. The coupling is designed to provide a secure and tight fit to prevent leakage and ensure efficient drilling.

Applications:

R25 drill rods are commonly used in vertical and inclined boreholes in underground mining and tunneling applications. They are often used in narrow tunnels for drilling blast holes and in wells for geotechnical investigations. R25 drill rods are also frequently used in infrastructure projects such as highway construction, tunneling, and dam construction.

Advantages:

R25 drill rods are highly durable and wear-resistant, making them ideal for use in challenging underground conditions. They have high tensile strength, which means they can withstand significant pressure from the drill rig. The threaded connection system allows for easy assembly and disassembly of the drill string, which saves time and increases efficiency on the job site. Additionally, R25 drill rods have a longer lifespan compared to other types of drill rods, which can help reduce costs over time.

R25 Drifting & Tunneling Tools

R25 (1″) bit thread, Button bit diameter: 33mm, 35mm, 37mm, 38mm, 41mm, 43mm

Cross bit diameter: 33mm, 35mm, 38mm

Reaming bit, 6° taper, bit diameter: 64mm, 76mm, 89mm

Pilot adapter, 6° taper, R25 thread, diameter: 26mm

Drifter rod, R32-Hex25-R25, length: 2200mm, 2400mm, 2600mm, 2800mm, 3090mm, 3700mm

Coupling sleeve, R25, 150mm length

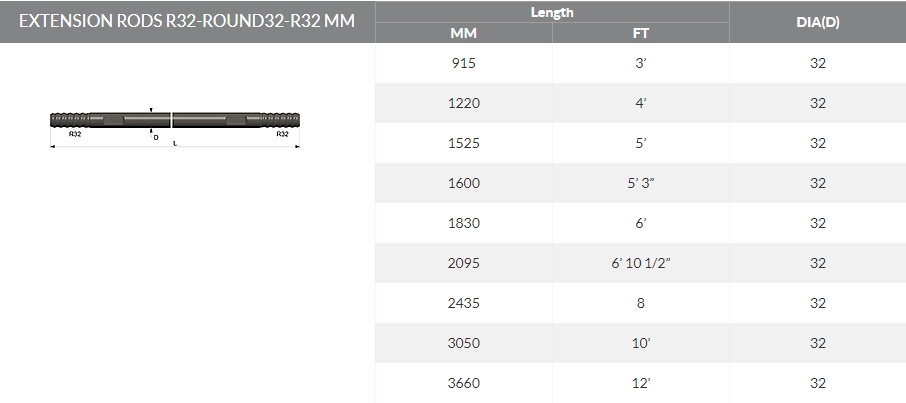

An R32 extension drill rod is a type of drilling tool used in underground mining and construction projects. It is a thin-walled, hollow steel rod with a diameter of 32mm and a length that can vary depending on the requirements of the project. The R32 extension drill rod is designed to be attached to a drilling rig and lowered into a borehole to reach deeper levels of the earth. It is typically used to extend the reach of the drill bit and can be threaded together with other R32 drill rods to create a longer drill string. The durability and strength of the R32 extension drill rod make it ideal for use in challenging underground conditions where the drill string may need to be rotated under high torque and pressure.

Construction:

R32 extension drill rods are usually constructed using high-grade alloy steel with a hollow core, which makes them lightweight but still strong enough to withstand the stresses of drilling. The rods are threaded on both ends to allow for easy connection to other rods, as well as to the drill bit and the drilling rig.

Size and Length:

The standard diameter of an R32 extension drill rod is 32mm (about 1.26 inches), but they can also be manufactured in larger diameters if needed. The length of the rods can vary depending on the specific drilling application, but they are typically available in lengths ranging from 1 to 6 meters (3 to 20 feet).

Thread Type:

R32 extension drill rods have a specific thread type that is used in conjunction with other components of the drilling system. The thread design is usually chosen based on the requirements of the project, and can be standard or customized if necessary.

Applications:

R32 extension drill rods are commonly used for underground drilling in mining and construction applications where a long reach is required. They can be used for a range of drilling techniques including rotary drilling, percussive drilling, and diamond drilling. These drill rods are ideal for use in directional drilling, as they are able to maintain a straight line while drilling at angles, even in very hard rock conditions.

Advantages:

R32 extension drill rods are known for their strength, durability, and wear resistance, making them a popular choice for many drilling applications. They are also relatively lightweight, which makes them easier to handle and transport. Additionally, the hollow core of the rods allows for high-pressure air or water to be pumped through them, which can be useful for clearing debris from the borehole during drilling operations.

Precision-hardened keys are lighter in weight and enable shorter shank lengths.

The shank design offers the highest piston-to-bit weight ratio, maximizing energy at the button face.

An airflow channel design and control minimize bit face plugging and eliminate unwanted pressurization of surrounding formations.

Custom and standard sizes are available up to 43 inches in diameter.

Full-gauge underreamers are designed for overburden conditions.

Thanks to SHANDIKE’s long history in drilling, we understand bits. First and foremost, we recognize the significance of a durable, effective design leading your tooling down the hole. Art Holte invented the key drive system. Consequently, our complete line of reverse circulation bits can be quickly changed with hand tools.

Precision-hardened keys are the cornerstone of our key drive system, replacing traditional splines. This allows for shorter shank lengths and lighter weight bits with very high piston-to-bit weight ratios. Delivering maximum energy to the button face means the drill is efficiently bringing rock chips to the surface, rather than wasting time creating dust.

Tapered airflow channels reduce the likelihood of bit face plugging to ensure the hammer continues to operate in all types of conditions. Careful control of airflow better directs air to the center of the bit face, helping to eliminate the unwanted pressurization of surrounding formations—making drilling in sensitive sites less risky.

SHANDIKE RC bits are available in a variety of shank styles. An innovative two-piece design utilizes tungsten carbide or optional diamond buttons for the utmost in durability. Sizes range up to 43 inches (1092mm). Our flexible design, manufacturing, and heat treatment processes are capable of adapting to meet your needs. RC underreamer bits are also available.

The drill bit violently and low impact breaks the rock during rock drilling, thereby achieving the purpose of drilling boreholes in the rock. During use, alloy teeth inevitably collide and rub against rocks, resulting in wear. Wear is a normal failure mode of alloy teeth without fracture. The ultimate failure mode of the drill bit is also due to the wear of the alloy teeth, which makes it impossible to continue drilling rocks and ends. Wear is usually caused by collisions and friction between alloy teeth and rocks during the drilling process. Hard particles in the rock first plow into the softer bonding parts of the alloy teeth, causing them to be worn away first. In the subsequent cutting motion, WC grains that lose their bonding phase protection peel off, thereby grinding off a small part of the alloy teeth. Under the loading of rock drilling machinery, the alloy teeth continuously wear out, and the relative motion and contact area between the alloy and the rock also increase, further accelerating the wear of the alloy teeth.

High wind pressure impactor is a type of rock drilling tool, but unlike other rock drilling tools, it always stays at the bottom of the hole during the drilling process, and the piston directly impacts the drill bit. Compressed gas enters the impactor through the drill rod and is then discharged from the drill bit, and the exhaust gas is used to discharge slag. The rotary motion of the impactor is provided by the rotary head of the drilling rig, and the axial thrust is provided by the propulsion mechanism of the drilling rig, which is transmitted to the impactor through the drill rod.

2、 Structural principle

The down the hole impactor is composed of a piston, an inner cylinder, a valve seat, a check valve, and drill bit accessories installed in a slender outer cylinder. The upper end of the outer cylinder is equipped with an upper joint with a plate handle and a connecting thread, and the lower end is equipped with a threaded clamping sleeve. The clamping sleeve is mainly used to transmit thrust and rotary motion to the drill bit, and the clamping ring controls the axial movement of the drill bit. The check valve is used to prevent debris such as rock slag from entering the impactor when the supply of compressed air is stopped. During the drilling process, the drill bit is pushed into the impactor and pressed against the clamping sleeve. At this time, the piston directly impacts the drill bit into rock drilling. When the drill bit is lifted off the bottom of the hole, it begins to forcefully blow and discharge slag.

3、 Precautions for use and operation

DTH Hammer Button Bits, also known as Down The Hole Hammer Button Drill Bits, are essential components of drilling equipment that are particularly prevalent in various industries including mining, drilling, and quarrying. These bits are specifically engineered for use with down the hole hammers, which utilize high-pressure air or gas to power the piston within the hammer, resulting in high-frequency impacts. Simultaneously, the drill bit rotates, effectively breaking apart rocks. Applications for DTH Hammer Button Bits are extensive and include water well drilling, quarry operations, construction projects, blasting activities, open-pit mining, and underground mining operations.

1. Definition and Purpose:

DTH Hammer Button Bits are specialized drill bits designed to work in conjunction with down the hole hammers. These hammers operate by utilizing high-pressure air or gas to drive the internal piston, creating powerful, high-frequency impacts. Meanwhile, the drill bit itself rotates, which facilitates the breaking of rock formations. These bits are commonly employed in a variety of scenarios, such as drilling for water wells, extracting stone from quarries, conducting construction work, preparing for blasting operations, and extracting minerals from both open-pit and underground mines.

2. Structure and Characteristics:

The structure of DTH Hammer Button Bits comprises a drill body and multiple tungsten carbide buttons. The main body of the drill bit is typically constructed from high-quality alloy steel, which offers superior strength and exceptional resistance to wear. Tungsten carbide buttons are embedded within the drill body and serve the critical function of directly breaking down rock formations.

Characteristics of these bits include:

– Wear Resistance: The utilization of hard materials such as tungsten carbide ensures that DTH Hammer Button Bits possess a high degree of wear resistance, allowing them to maintain sharp cutting edges over extended periods.

– Efficiency: The synergy between the wear resistance and impact capabilities of the drill bit significantly enhances drilling speed, thereby boosting overall work efficiency.

– Stability: The design of the drill bit ensures a stable drilling process, minimizing deviation and damage that could result from vibrations.

3. Types and Specifications:

There exists a diverse range of DTH Hammer Button Bits, each tailored to meet the unique requirements of different customers. These types are commonly categorized based on several factors, including diameter. Different diameters of drill bits are suitable for drilling holes of varying sizes to accommodate specific aperture requirements. Common diameters include…

Common diameters include 38mm, 45mm, 51mm, 60mm, 76mm, 89mm, 102mm, 115mm, 127mm, 140mm, and 152mm, among others. These diameters cater to a wide array of drilling applications, ensuring that there is a suitable bit for every project’s specific needs. Furthermore, the specifications can also vary based on the length of the bit, the number of buttons, and the type of carbide used, providing even more options for customization.

In summary, DTH Hammer Button Bits are indispensable tools in the drilling industry, offering a combination of durability, efficiency, and stability that makes them ideal for a variety of challenging environments and applications. Their robust design and the use of high-quality materials ensure that they can withstand the rigors of heavy-duty drilling, making them a preferred choice for professionals in mining, construction, and quarrying industries.

There are multiple well-known DTH Hammer Button Bits brands and suppliers in the market, such as Luoyang Shandike Mechanical Equipment Co., Ltd

| Specification of dth hammer button bits: | Diameter: (mm) |

| 1-2 inch low air pressure DTH bits Shank: BR1, BR2, DHD2.5 | 57/64/70/76/80/82/90 |

| 3 inch high Air pressure DHT bits Shank: BR3,DHD3.5,COP34,COP32,QL30,M30,IR3.5 | 85 / 90 / 95 / 100 / 105/110 |

| 4 inch high Air pressure DHT bits Shank:DHD340,COP44,M40,SD4,QL40 | 105 / 110 / 115 / 120 / 127/130 |

| 5 inch high Air pressure DHT bits Shank:DHD350,COP54,M50,SD5,QL50 | 133 / 140 / 146 / 152 / 165 |

| 6 inch high Air pressure DHT bits Shank:DHD360,M60,SD6,QL60,COP64 | 152 / 165 / 178 / 190 / 203 |

| 8 inch high Air pressure DHT bits Shank:DHD380,COP84,M80,SD8,QL80 | 195 / 203 / 216 / 254 / 305 |

| 10 inch high Air pressure DTH bits Shank:SD10, NUMA100 | 254/270/279/295/305 |

| 12 inch high Air pressure DTH bits Shank:SD12,DHD1120,NUMA120,NUMA125 | 305/330/343/356/368/381 |

Hex32 drifter rods are primarily employed within the context of fully hydraulic drifting jumbos, serving as a cornerstone in a range of underground excavation and drilling applications. These sophisticated drilling tools are indispensable for a multitude of tasks, including the blasting and excavation of roadways in underground mines, the drilling of anchor holes for structural support, and the excavation of various types of tunnels such as those used for traffic, hydropower engineering diversions, and other underground engineering projects. Designed to tackle the diverse hardness levels of rocks encountered in such environments, Hex32 drifter rods are renowned for their exceptional wear resistance, flexibility, and prolonged service life, making them a reliable choice for demanding drilling conditions.

The specifications of Hex32 drifter rods typically encompass:

Length: This varies depending on the specific model and the intended application, allowing for customization to suit varying depths and drilling requirements.

Diameter: Standardized at 32mm, this diameter ensures compatibility with a wide range of drilling equipment and accessories designed for Hex32 rods.

Weight: Determined by the rod’s length and the material composition, which can include high-strength steel alloys for optimal durability and performance.

Thread Type: Commonly featuring the R32 thread configuration, this standardized threading allows for seamless connection and disconnection of rods during drilling operations.

Manufacturers such as SHANDIKE offer a comprehensive range of Hex32 drifter rods, catering to diverse lengths and thread configurations to meet the precise needs of various drilling projects. These rods are frequently utilized in mining and construction ventures where the demand for precise, efficient, and reliable drilling is paramount.

For detailed information regarding Hex32 drifter rods, including pricing, availability, and customized options tailored to specific project requirements, it is advisable to reach out to manufacturers like SHANDIKE. Their expertise and experience in the field ensure that you receive the highest quality drifter rods suited to your unique drilling challenges.

| Type:Drill Pipe Rod Hex Rod Male-male rod Male-female (Speed rod) Guide tube | ||||

| Thread: R25, R28,R32, R35, T38, T45,T51, ST58, GT60, ST68. | ||||

| Length:900mm ~ 5490mm Or Customized. | ||||

| Material:Carbon steel | ||||

| Application:Tunnelling,Mining,Quarrying,Blasting and Infrastructure | ||||

| Diameter:39mm, 46mm, 52mm | ||||

| Drill Rod Type:Drifter Rod, Speed Rod, Extension Rod, MF-Rod | ||||

| Rock Formation:Hard / Medium hard / Soft Rock Formation | ||||

| Advantage:wear resistant,factory prices,high quality |

The 3660mm MF rod is a specialized drilling tool employed in a range of industrial applications, particularly in mining and rock excavation. The “MF” designation stands for “male-female,” denoting the type of connection at the rod’s ends. This connection facilitates swift assembly and disassembly during drilling operations. Crafted from high-quality alloy steel, these rods are built to last, ensuring durability and resistance against wear and tear.

The 3660mm length is a standard size in the industry, compatible with drilling equipment designed to handle such dimensions. They are extensively used in underground mining, tunneling, and other heavy-duty drilling projects. The alloy steel construction guarantees that the rods can endure the rigorous conditions encountered during these operations, offering a dependable and long-lasting solution for drilling requirements.

T51 MF Rod Specifications:

– Length: 3.66 meters

– Thread System: T45/T51

– Connection Type: Male/Female

– Application: Benching and long hole drilling

– Enhanced Drilling Precision: When used as the first rod in a standard drill string, it improves accuracy.

– Speed Rod Design: Capable of producing straighter holes and achieving at least a 10% higher penetration rate in favorable rock conditions compared to traditional rod and coupling sleeve systems.

Applications:

– Underground Mining

– Tunneling and Quarrying

– Suitable for various rock types, including Granite, Basalt, and Limestone

Competitive Advantages:

– Utilization of High-Grade Raw Materials

– Manufactured from Premium Steel using Advanced CNC Machinery and Heat Treatment Processes

– Features High-Strength Chromium-Molybdenum Steel with Excellent Fatigue Strength and Wear Resistance

Atlas / Furukawa / / Tamrock GT60 Half-bridge Threaded Coupling Sleeve Drill pipe speed extension drill

An elongated rod is attached to the sleeve, which is crafted from high-quality steel and precision-machined using CNC technology to guarantee consistent and reliable quality control. When utilizing a drilling machine, a conventional male adapter and club drift must be connected via a coupling bar adapter that is allowed to float, ensuring contact at both ends for efficient energy transfer.

The coupling sleeve operates similarly to interconnected links, with an intermediate connection sleeve featuring a stop mechanism to prevent over-tightening onto the drill rod.

This product is primarily used in mining, compression, tunneling, quarrying, and other related industrial equipment. It is designed and manufactured according to customer specifications.

Main features

High performance: The GT60 coupling sleeve is made of high-quality materials and advanced technology, with high strength and wear resistance, and can withstand the enormous pressure and friction during the drilling process.

Strong universality: This sleeve is suitable for various drilling rods and tools, with wide compatibility, making it convenient for users to choose and replace in different operating environments.

Easy to install and disassemble: The GT60 coupling sleeve adopts a threaded connection method, which is convenient and fast to install and disassemble, improving the efficiency of drilling operations.

Material and Processing

Material: The GT60 coupling sleeve is usually made of high-quality materials such as high manganese steel, alloy steel, or hard alloy to ensure its high strength and wear resistance.

Processing method: The sleeve is processed through precision forging and heat treatment processes to ensure the accuracy and stability of its internal structure and external dimensions.

Reverse circulation drill bit is a key component in reverse circulation drilling technology, which is widely used in geological drilling, mine rescue, engineering construction and other fields. The main feature of reverse circulation drilling technology is that the flushing medium (such as water, mud, or air) rises at a high speed in the center hole of the drill rod, effectively removing drilling debris and improving drilling efficiency.

Drt reverse circulation drill bits is made by quality tungsten carbide tips and steel with forging process, Combining the hardness and the high impact toughness of the steel makes the drt revest circulate DTH drill bit widely used in hard formation drilling, especially in the water well drilling, mining and rock drilling. Except for DTH hammer bit, we also supply thread button bits, retrac button bit, taper button bits, drill rods, shank adapters, coupling sleeve etc drilling tools.

Working principle of reverse circulation drill bit

In reverse circulation drilling, the drill bit is connected to the power device through the drill string, and the power device drives the drill string and drill bit to rotate for drilling. At the same time, the flushing medium flows downwards from the wellhead through the annular space between the drill pipe and the hole wall or between the inner and outer pipes of the double walled drill pipe, and then returns to the surface from the drill pipe or the inner pipe of the double walled drill pipe after reaching the bottom of the hole, forming a reverse circulation. During this process, the water holes or special designs on the drill bit allow the flushing medium to flow back smoothly, carrying the drill cuttings back to the surface.

Advantages of reverse circulation drill bit

Strong slag discharge capacity: Due to the high-speed rise of the flushing medium in the center hole of the drill rod, drilling cuttings are easily carried to the surface, reducing the phenomenon of repeated crushing at the bottom of the hole and improving drilling efficiency.

Small disturbance to the borehole wall: During the reverse circulation drilling process, the flushing medium has a relatively small flushing effect on the borehole wall, which is beneficial for drilling stability and reduces accidents such as buried drilling and broken drill rods inside the borehole.

Water saving drilling: When air is used as the circulating medium, water-saving drilling can be achieved, especially suitable for construction in arid and water scarce areas.

Possible characteristics of DRT reverse circulation drill bit

Although specific information on DRT brand reverse circulation drill bits is limited, based on the general characteristics of reverse circulation drill bits, it can be inferred that DRT reverse circulation drill bits may have the following features:

Efficient drilling: Advanced drill bit design and materials are used to improve drilling speed and efficiency.

Strong durability: After special processing, the wear resistance and service life of the drill bit are improved.

Strong adaptability: Suitable for different geological formations and drilling needs, can be adjusted and optimized according to actual situations.

application area

DRT reverse circulation drill bits may be widely used in the following fields:

Geological drilling: used for mineral exploration, hydrogeological survey, etc.

Mine rescue: Used in mining accidents to quickly drill into rescue wells and provide a lifeline.

Engineering construction: such as pile foundation construction, foundation treatment, etc.

In summary, DRT reverse circulation drill bit, as a key component in reverse circulation drilling technology, has the characteristics of efficient drilling, strong durability, and strong adaptability, and is widely used in geological drilling, mining rescue, and engineering construction fields. For more specific information, it is recommended to consult DRT brand or professionals in related fields directly.

If you need a Drt reverse circulation drill bit, please contact us and we will provide you with the best price and solution:

Email: [email protected]

Whatspp: +86 19937978951

Coupling sleeve R32, The R32 specification coupling sleeve is a widely used connecting component in industries such as mining, stone mining, and construction. Here is a detailed explanation of it:

1、 Definition and purpose

Definition: Coupling sleeve R32 is a sleeve shaped connector with R32 thread specification, used to connect two or more rod-shaped tools such as drill rods and drill rods to achieve length extension or tool replacement.

Purpose: Mainly used for rock drilling operations in mining, drilling operations in stone mining, and foundation pile driving operations in construction. By connecting drill rods of different lengths, it is possible to adapt to drilling requirements at different depths.

2、 Main features

High strength: Coupling sleeve R32 is usually made of high-strength materials, such as high-quality alloy steel or stainless steel, to ensure that it will not be damaged when subjected to large torque and axial forces.

High precision: The threaded part is precision machined to ensure a tight fit with rod-shaped tools such as drill rods, avoiding looseness or detachment during operation.

Wear resistance: Due to the complexity of the working environment, the threaded part of the coupling sleeve R32 is usually specially treated to improve its wear resistance and extend its service life.

3、 Specification and Model

Thread specification: R32, indicating an outer diameter of 32 millimeters for its threads.

Length: Depending on the manufacturer and usage, its length may vary, but it usually fluctuates within a certain range.

Model: It may be subdivided based on factors such as connection method (such as full bridge, half bridge, etc.), material, processing accuracy, etc.

4、 Selection and Precautions

Brand selection: Choosing products from well-known brands usually means higher quality and more reliable performance.

Specification matching: When purchasing, it is necessary to ensure that the thread specifications of the selected product match the rod-shaped tools such as drill rods that need to be connected.

Quality inspection: After receiving the product, a quality inspection should be conducted to ensure that there are no defects such as cracks or rust.

Usage and maintenance: During use, the wear of the coupling sleeve should be regularly checked, and severely worn components should be replaced in a timely manner. Meanwhile, attention should be paid to keeping it clean and dry, and avoiding prolonged exposure to harsh environments.

In summary, Coupling sleeve R32 plays an important role as a connecting component in industries such as mining, stone mining, and construction. When selecting and using, full consideration should be given to its characteristics, specifications, and precautions to ensure that it can work normally and stably.

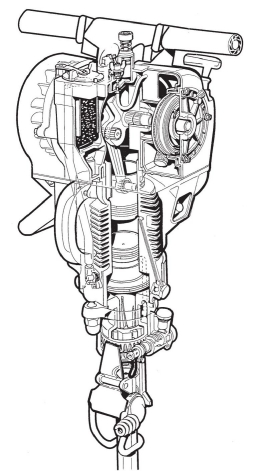

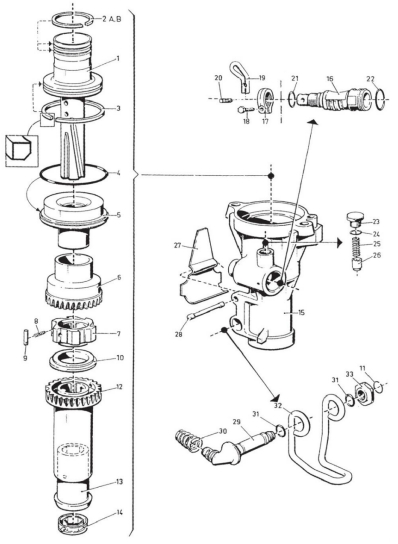

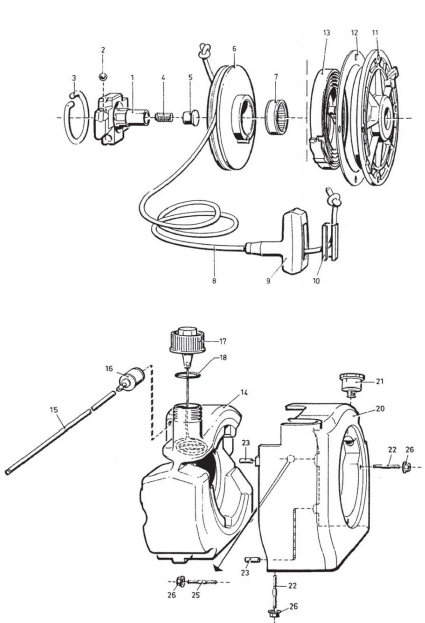

Detailed instructions on the technical specifications, operating methods, maintenance, troubleshooting, and other aspects of YN 27 and YN 27C internal combustion rock drills. The document first introduces the basic structure and working principle of the rock drill, and then elaborates in detail on the preparation work before operation, start-up, rock drilling, tool replacement, parking, impact operation, and operating precautions. In addition, specific steps and troubleshooting methods for maintenance, inspection, and adjustment work are provided.

| 1.Weight of main machine: | 27kg |

| 2.0verall dimensions: | 746×315×229mm |

| 3.Type ofengine: | single cylinder,air cooled two strokes |

| 4.Cylinder Diameter X stroke ofpiston: | 58×70mm |

| 5.Rotating speed of engine: | ≥2450r/min |

| 6.Displacement of engine piston: | 185cm³ |

| 7.Type of carburetor: | hand needle valve,no floating type |

| 8.Ignition system: | ontrollable silicon,contactless system |

| 9.Drlling speed:(mean value offive holes) | ≥250mm/min |

| (After holing,drill φ34,with drill rod of 600mm in length,is drilled vertically downward into medium hard granite(f=8-12)to make five holes in succession.The mean value of the five holes are counted as the speed.) | |

| 10.Max drilling depth: | 6m |

| 11.Fuel consumption: | ≤0.12L/m |

| 12.Tank capacity: | ≥1.14L |

| 13.Mixture ratio of gasoline and lubricating oil(in volumes): | 12:1 |

| 14.End of dill rod dimensions: | 22×108mm |

| 15.Rotating speed of drill rod: | ≥200r/min |

| 16.Clearance of spark plug: | 0.5-0.7mm |

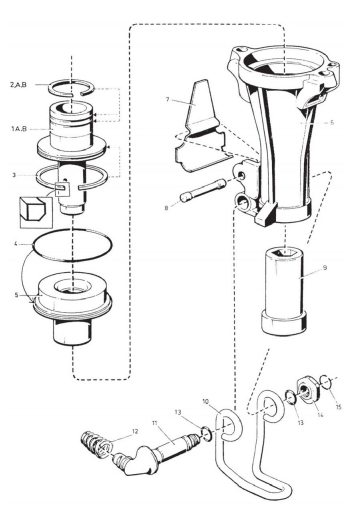

| Fig.No. | Qty | Description |

| 1 | 1 | Hammer piston |

| 2 | 1 | Piston ring set |

| 2A | 1 | Piston ring |

| 2B | 1 | Piston ring |

| 3 | 1 | Piston ring |

| 4 | 1 | O-ring |

| 5 | 1 | Hammer piston guide |

| 6 | 1 | Ratchet housing |

| 7 | 1 | Ratchet wheel assy |

| 8 | 6 | Spring |

| 9 | 6 | Roller |

| 10 | 1 | Spacer |

| 11 | 1 | Lock ring |

| 12 | 1 | Rotating sleeve |

| 13 | Collet assy | |

| 14 | 1 | Gasket |

| 15 | 1 | Drill chuck assy |

| 16 | 1 | Operating shaft |

| 17 | 1 | Locking nut |

| 18 | 1 | Screw |

| 19 | 1 | Lever |

| 20 | 1 | Pin |

| 21 | 1 | O-ring |

| 22 | 1 | 0-ring |

| 23 | 1 | Spring housing |

| 24 | 1 | O-ring |

| 25 | 1 | Spring |

| 26 | 1 | Plunger |

| 27 | 1 | Yoke spring |

| 28 | 1 | Lock pin |

| 29 | 1 | Yoke bolt assy |

| 30 | 1 | Spring |

| 31 | 2 | O-ring |

| 32 | 1 | Drill yoke |

| 33 | 1 | Drill yoke nut |

| Fig.No. | Qty | Description |

| 1 | 1 | Hammer piston |

| 2 | 1 | Piston ring set |

| 2A | 1 | Piston ring |

| 2B | 1 | Piston ring |

| 3 | 1 | Piston ring |

| 4 | 1 | O-ring |

| 5 | 1 | Hammer piston guide |

| 6 | 1 | Drill chuckassy |

| 7 | 1 | Yoke spring |

| 8 | 1 | Lock pin |

| 9 | 1 | Rotating sleeve |

| 10 | 1 | Drill yoke |

| 11 | 1 | Yoke bolt assy |

| 12 | 1 | Spring |

| 13 | 2 | O-ring |

| 14 | 1 | Drill yoke nut |

| 15 | 1 | Lock ring |

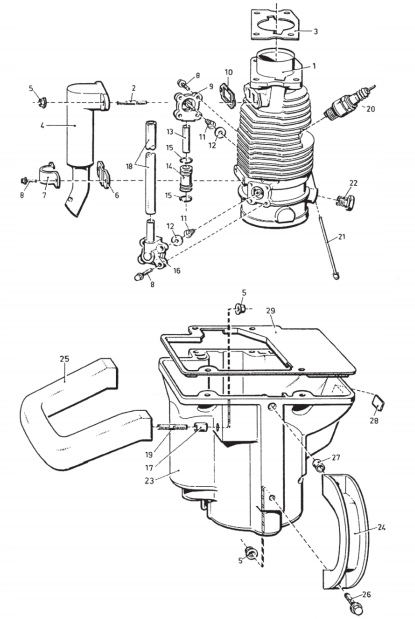

| Fig.No. | Qty | Description |

| 1 | 1 | Cylinder |

| 2 | 2 | Stud bolt |

| 3 | 1 | Gasket |

| 4 | 1 | Exhaust pipe |

| 5 | 6 | Nut |

| 6 | 1 | Washer |

| 7 | 1 | Clip |

| 8 | 10 | Screw |

| 9 | 1 | Blow valve seat |

| 10 | 1 | Gasket |

| 11 | 2 | Spring |

| 12 | 2 | Valve washer |

| 13 | 1 | Tube |

| 14 | 1 | Rubber hose |

| 15 | 2 | Lock ring |

| 16 | 1 | Intake valve seat |

| 17 | 2 | Bushing |

| 18 | 1 | Suction duct |

| 19 | 2 | Screw |

| 20 | 1 | Spark plug |

| 21 | 1 | Cleaning needle |

| 22 | Inlet valve | |

| 23 | 1 | Shield |

| 24 | 1 | Handle assy |

| 25 | 1 | Side handle |

| 26 | 2 | Bolt |

| 27 | 1 | Bushing |

| 28 | 1 | Label |

| 29 | 1 | Gasket |

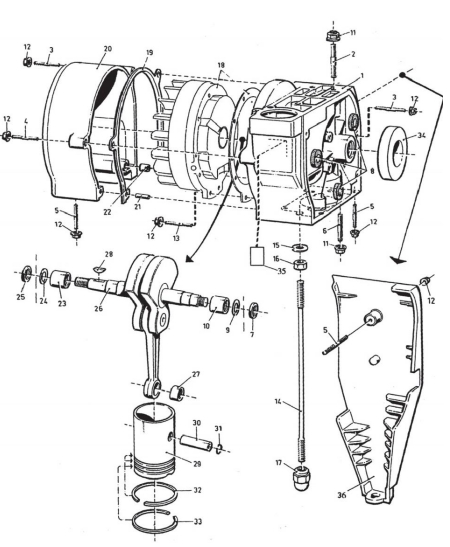

| Fig.No. | Qty | Description |

| 1 | 1 | Crank case assy |

| 2 | 3 | Stud |

| 3 | 4 | Stud |

| 4 | 1 | Stud |

| 5 | 4 | Stud |

| 6 | 4 | Stud |

| 7 | 1 | Retainer ring |

| 8 | 3 | Rubber cushior |

| 9 | 1 | Spacer |

| 10 | 1 | Needle bearing |

| 11 | 7 | Nut |

| 12 | 19 | Nut |

| 13 | 10 | Stud bolt |

| 14 | 2 | Draw bolt |

| 15 | 2 | Spring washer |

| 16 | 2 | Nut |

| 17 | 1 | Cap nut |

| 18 | 1 | Flywheel and Magneto classis parts |

| 19 | 1 | Gasket |

| 20 | 1 | Crankcase cover |

| 21 | 1 | Pin |

| 22 | 1 | Bushing |

| 23 | 1 | Needle bearing |

| 24 | 1 | Spacer |

| 25 | 1 | Retainer ring |

| 26 | 1 | Crank shaft assy |

| 27 | 1 | Needle bearing |

| 28 | 1 | Key |

| 29 | 1 | Engine piston set |

| 30 | 1 | Gudgeon pin |

| 31 | 2 | L ock ring |

| 32 | 2 | Piston ring |

| 33 | 1 | Piston ring |

| 35 | 1 | Plate |

| 36 | 1 | Wearing plate |

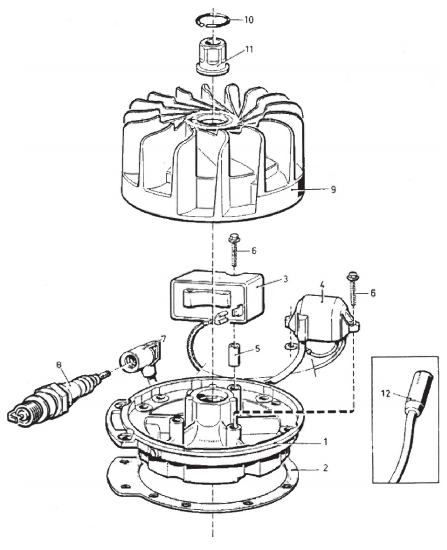

| Fig.No. | Qty | Description |

| 1 | 1 | Magneto chassis |

| 2 | 1 | Gasket |

| 3 | 1 | Electronic unit |

| 4 | 1 | Induction coil set |

| 5 | 1 | Bushing |

| 6 | 4 | Bolt |

| 7 | 1 | Cable terminal |

| 8 | 1 | Spark plug |

| 9 | 1 | Flywheel assy |

| 10 | 1 | Lock ring |

| 11 | 1 | Nut |

| 12 | 1 | Ignition cable |

| Fig.No. | Qty | Description |

| 1 | 1 | Clutch body |

| 2 | 4 | Ball |

| 3 | 1 | Snap ring |

| 4 | 1 | Stop screw |

| 5 | 1 | Rubber plug |

| 6 | 1 | Starter pulley |

| 7 | 1 | Needle bearing |

| 8 | 1 | Starter rope set |

| 9 | 1 | Starter handle |

| 10 | 1 | Rope bracket |

| 11 | 1 | Starter covei |

| 12 | 1 | Gasket |

| 13 | 1 | Starter spring |

| 14 | 1 | Fuel tank assy |

| 15 | Fuel tube | |

| 16 | 1 | Fuel filter |

| 17 | 1 | Tank cap |

| 20 | 1 | O-ring |

| 21 | 1 | Fuel tank cover |

| 22 | 1 | Guide rope piles |

| 23 | 15 | Stud |

| 24 | 2 | Pin |

| 25 | 1 | Stud bolt |

| 26 | 6 | Nut |

| Fig.No. | Qty | Description |

| 1 | 1 | Control |

| 2 | 1 | Pin |

| 3 | 4 | Screw |

| 4 | 1 | Nut |

| 5 | 1 | Wing nut |

| 6 | 1 | Spring |

| 7 | 1 | Retainer cup |

| 8 | 1 | 0-ring |

| 9 | 1 | Fuel needle assy |

| 10 | 1 | Fuel valve seat |

| 11 | 1 | O-ring |

| 12 | 1 | Nozzle,lower |

| 13 | 1 | Adjusting screw |

| 14 | 1 | Nut |

| 15 | 1 | Throttle set |

| 16 | 1 | Nut |

| 17 | 1 | Spring washer |

| 18 | 1 | Throttle control |

| 19 | 1 | Spring |

| 20 | 1 | Spring seat |

| 21 | 1 | Retaining ring |

| 22 | 1 | Throttle seat |

| 23 | 2 | O-ring |

| 25 | 2 | Leaf valve |

| 26 | 2 | Support |

| 27 | 4 | Spring washer |

| 28 | 1 | Stud |

| 29 | 1 | Lock clip |

| 30 | 2 | Valve sheet |

| 31 | 2 | Handle sleeve |

| 32 | 1 | Handle assy |

| 33 | 1 | Filter housing |

| 34 | 2 | O-ring |

| 35b | 1 | Filter element |

| 36 | 1 | Gasket |

YN27C rock drill machine CONSTRUCTION

1.Engine:The engine is a hand operated single cylinder and two stroke petrol engine with air cooling,reflux air conversion,no contact ignition,and no floating-type carburetor.It is composed of control parts,starter parts,oil tank parts,flywheel parts,crankshaft,connecting rod,crankshaft case parts,shield parts,magneto parts,piston parts and cylinder parts.

2.Air compressor:The engine piston and hammer piston are mounted separately in the upper and lower place of the cylinder.These two pistons move up and down synchronously.The hammer piston and the bigger bore of the cylinder form a compression chamber,Which together with air inlet and outlet valves and ventilator valves,form the air compressor.It is composed of hammer piston parts and cylinder parts.

3.Rock drill:It is composed of hammer piston parts,rotation mechanism parts and drill chuck parts.

Lubrication and Cooling Action

Fuel used by the drill is 12:1,that is ,a mixed oil in the proportion 12 parts of gasoline to 1 part of lubricating oil.In operation,mixed oil enters into the crankshaft in fog to lubricate all parts of the crankshaft and the cylinder.During burning,gasoline burns,most of lubricating oil flow into all touching parts through the cylinder space to make them get complete lubrication.

The cylinder of engine is cooled by wind from the flywheel through the surface of emitting heat plates.

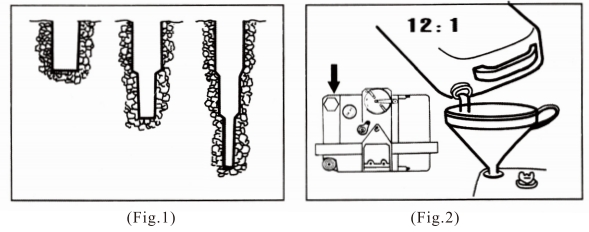

YN27·YN27C Operation

(1)Preparation before starting:

Preparing with mixed oil,drill rod,bit,funnel with filter net,some service tools and spark plug,etc.The ratio of mixed oil is 12:1.When the temperature is high or the quality of the lubricating oil is different,it can be adjusted to 6:1 to 10:1 as appropriate.

1.Gasoline:Use gasoline of 93#or 95#.

2.Lubricating oil:Use two-stroke gasoline engine lubricating oil or automotive lubricant,or low-condensation lubricant at lower temperature.

3.Length of dill rods and diameter of the carbide percussive drillbit:When drilling,a group of drill rod length with different size should be prepared in order to operate

conveniently and safely.They are 0.6m,1.1m,1.6m,2.0m,2.6m,3.0m,selecting them according to the depth of hole.In operating,o.6 is used to drill at first,then 1.1m instead of smaller one(Fig.1),then they are easy to choose and can work normally.

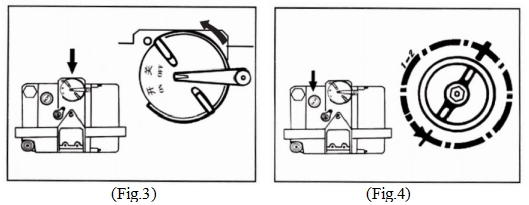

1、Erect the machine to support the handle of the control body ,and fill fuel into the gasoline tank.(Fig.2)

2.Close the air filter.(Fig.3)

3.Rotate the wing nut of fuel valve in counter clockwise one cycle or two to open it.(Fig.4)

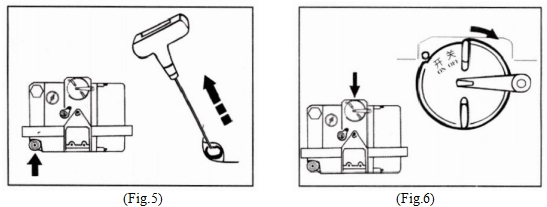

4.Pull the starter wire rope slowly for several times to let the mixed oil into the cylinder.When combustible gas in the cylinder burns,stop pulling.(Fig.5)

5.0pen the air filter.(Fig.6)

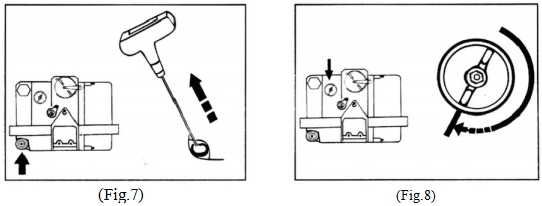

6.Pull the starter wire rope rapidly and powerfully to start.(Fig.7)After that the machine runs idly for several minutes in order to heat it,then turn the wing nut of fuel valve clockwise ,its rotating speed rises gradually.If abnormal sound with fog in the exhaust pipe,that means fuel supply is not enough.Right now,please turn the wing nut of the fuel valve in a counter clockwise direction and increase the amount of fuel supply.

7.Attention points for starting:

Mixed oil entering into the cylinder being too much or insufficient will be adverse to the starting of the engine.The operator is asked to make a correct judgement for the amount of the mixed oil in the cylinder.The method is to observe the state if a jet of fuel emerges from the exhaust pipe.If poor,please make the wing nut of fuel valve rotate in counter clockwise direction,open fuel valve full.Pull wire rope until combustible gas enter the cylinder burns and the engine be started.If a jet offuel emerges from the exhaust pipe,that means the fuel supply is too much,please make the wing nut of fuel valve rotate in clockwise direction and pull the starter wirerope for several times until it is operating then adjust the wing nut of the fuel valve in a appropriate position.(Fig.8)

(3)Drilling

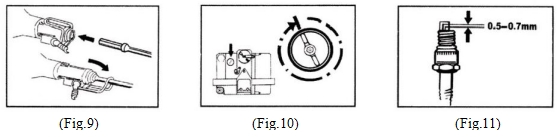

1.Fitting rod:Press the throttle valve with thumb to make the machine operate with lower speed ,then insert the shortest drills rod into the rotating sleeve.Snap down the yoke so that bit will notjump out.(Fig.9)

2.Start to drilling:Select an appropriate position.Slow down the rotating speed of the machine,use a foot to guide bit for facilitating the make hole.

3.Drilling hole:Release the throttle valve ,let the machine run at full speed.During operation,add appropriate pressure so that no jumping occurs to the machine.If the rotating speed of the machine is too low,adjust the fuel valve to raise its speed.

(4)Changing of rod

(4)Changing of rod Changing of rod ,press the throttle valve to reduce its rotating speed Snap up the yoke by foot,take out the bit and replace another one.Snap down the yoke and then accelerate the machine to full speed.

(5)Stopping:

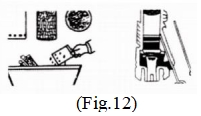

Stop to work for short time,only press the throttle valve ,or close the air filter.Stop to work a long time,the fuel valve should be closed.(Fig.10)to avoid the too much oil enters into the cylinder.

(6)Hammering:

If digging,breaking,splitting or ramming:

1.To YN27 dismantle the rotating sleeve and mount the notch of the hammer sleeve alingning with the round pin in the drill chuck cover,and dismante the vetilating pipe between the cylinder and the drill chuck cover assy,then all hammering operations are able to be carried out.

2.To YN-27C you can operate in(Fig .12a)manner.

(7)Attention points for operation:

1.Fuel filling:only after the machine is stopped.

2.If the machine misfires,make an inspection.Don’t pull the starter wire rope vigorously to avoid damage to the Parts.

3.During operation ,don’t press the machine by human body to avoid to valid accidents when a bit breaks

4.When a bit is blocked ,don’t move it directly with the machine.

5.At the initial use of a new machine ,the throttle valve is not to be regulated high.Only after the machine is well mastered ,its speed can be regulated higher.

6.Working in terribly hot area,be cautious that the operation period is not too long.When the temperature of the machine is too high,a short stop is necessary till it gets cool.

7.To avoid corrosion,the machine should be stored at dry places.

Maintenance,Inspection and Adjustment

(1)To observe strictly the maintenance of the machine tool can not only ensure reliable running of machine,but also prolong its service life.

1.Before filling into oil tank,mixed oil must be filtered.

2.After starting,the machine tool should beatitude without any loads for 2-3 minutes to lubricate all sides in order to reduce trouble and prolong its life.

3.Everyday,operating 4 hour,take out the filter and wash itin gasoline.

4.Every week,outer of the machine and entitling heat plate of cylinder should be cleaned to send out heat.

Diagram of Air filter

5.When the machine is running,the deposited carbon is easily formed in the gas duet and on the other parts.Especially the bevel gas duct in cylinder must be assured of its free flow.When cleaning the bevel gas duct, switch down the inlet valve,take out cleaning needle and wipe out the deposited carbon in the bevel gas duct by the needle.(Fig.12)The inlet valve should also be kept lean.Several holes in the valves should be ensured free

passage to allow free motion of the steel ball.

6.When running of the machine is abnormal make an overall inspection of engine or make carbon cleaning ,to wipe out carbon accumulated piston ring ,engine piston and impact piston ,exhaust hole in cylinder wall and spark gap.Dirt on the flywheel and magneto should also be taken away.

(2)Attention points for Inspection:

1.Be sure that clearance between spark gap electrodes should be 0.5-0.7mm and constantly clean off carbon and dirties to avoid circuit break and reduction of ignition.(Fig.11)

2.Be sure that the clearance between the steel ball of inlet valve and round pin. 3.Be sure that seal of the check valve plate at the bottom of control body.

4.Be careful whether the angle of ignition is changed.The arrow of flywheel should be aligned with the sign on the crankshaft.

Disassembling and assembling

The machine must be assembled correctly,strictly sealed and perfect cleanness.After a period of service,the machine needs cleaning and repairing,so disassembling and assembling are of a common occurrence.The following cautions should be followed in disassembling and assume bluing:

1.Disassembling and assembling should be done according to procedure.The parts,especially the piston tings,are to be mounted on their original positions.No errors and missing are allowed.

2.All the parts need to be washed in kerosene or gasoline and applied a layer of lubrication oil.In assembling,drive tight all the screws nuts and spark plug.Before trial running,pull the starter wire rope slightly for several times,to see if it is rotating freely,then start the machine.

3.If the machine need an overall disassemble it according to the following procedure.For assembling,do it reversibly:

In partial repair,do not disassemble the parts,which need no repairing.Try by every means to disassemble only the parts wanting to be repaired.

4.In disassembling starter parts,take off the starter spring,Starter wire pulley and starter cover together,be careful that spring breaks.The connection between clutch and crankshaft is left threaded,disassemble it in clockwise.And the starter wire rope should be mount in the wire pulley slot according to the arrow on starter cover.

5.In assembling the torque mechanism parts,be sure that the straight and drift slots on the impact piston lever are correctly in mesh with impact piston lever are correctly in mesh with inner keys of upper rachet and rotating sleeve.

6.Be very careful in disassembling piston ring to avoid breaking.

7.In disassembling the engine piston,a notch on the piston should be faced to the hole of spark plug.

8.Connecting crankshaft case.Cylinder and drill chuck cover.Two long screw levers should be driven tight in interchangeably to ensure the uniform pulling force,but not too tight.

Trouble shooting

| Fault | Cause | Remedy |

| 1.The engine is difficult to star | 1.Fuel system:(1).Clogging or poor sealing of fuel passages(2).Clogging of gasoline filter.(3).Use of a wrong brand of gasoline,over flow fuel or water in the fuel.(4).Poor sealing of the check valve plate on the control body.(5).Overflow mixed fuel in cylinder 2 Flectric system(1).Irregular gap between the spark plug electrodes,and oil conation,accumulated carbon on its surfaceorloose fitting of the plug core.(2).Shifting of the flywheel from its normal position(Wrong angle forignition) 3.Pneumatic system:(1).Low ratio of compression:a.Carbon deposition in or wear the cylinder.Engine positon ring.b.Clogging of the bevel gas duct in cylinderc.Irregular clearance of the steel ball in the inlet valve.(2).Air in sufficient supply:Carbon deposition in the outlet on cylinder and the connection pipe of the Silencer. | Take out of needle valve,blow thefuel hole of oil tank and block it witha hand,then shave it to make astream of oil sprays from the hole. Disassemble it,inspect and clean it Choose or blend the fuel by theregulations.Disassemble it and adjust it.Close fuels door,disassemble inletValve,pull starter wire rope for several times,take away overflow fuel. Adjust the gap by the regulationclear away carbon or oil or replace the plug with a new oneAlign the arrow on flywheel with the sign on the crankshaft. Clean or replace it.Clean away carbon in time. Adjust the steel ball clearance between 0.5-0.7mm Clean itin time. |

| Fault | Cause | Remedy | |

| 2.The engine worksinefficiently. | 1.Unfitting fuel door or clogging of fuel passage.2.Carbon deposition in the bevel gas duct,inlet valve,outlet valve and piston ring. 1.Clogging in the center hole of | Adjust it. Clean it in time. Clean it | |

| 3.Poor removal of cuttings | drillrod.2.Damage of hexagonal seal ring. 3.Damage or clogging of inlet and outlet valve.4.1rregular size and shape of tool shank. | Replace itReplace them. Replace it. | |

| 4 Poor rotation of tool shank. | 1.Damage of upper ratchet or olive ring.2.Excessive wears of keys of impact piston rod,Upper ratchet,Rotatingsleeve and other relevant parts.3.Running inefficient of engine. | Replace Replace See the | it. them. above. |

| 1.Seizer of the impact piston and | Eliminating the case and make | ||

| 5.The engine races. | drill rod.2.Changing of the flywheel sing. | rotation sleeve run freely. Adjust it and align it with the sign of crankshaft. | |

| 6.Abrupt stop of the machine | 1.Clogging of the hole in oil tankcap.2.Wrong with electric of fuel system3.Carbon deposition in the machine or excessive temperature | Clean it. See the above.Give it a complete overhaul. | |

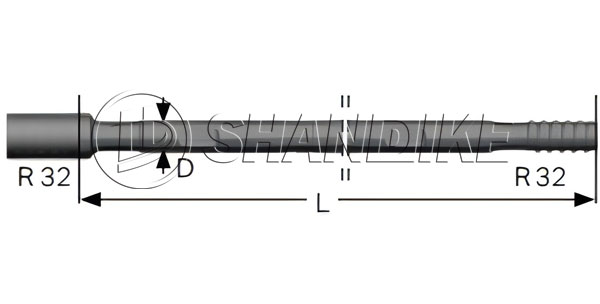

MF rod R32 is a specific specification quick connect drill rod, and the following is a detailed introduction to it:

1、 Basic characteristics

Specification and model: MF rod R32

Shape: usually circular or hexagonal to accommodate different usage needs.

Structure: Both ends are designed with threads for easy connection with other equipment or components; The middle is a hollow inner hole used as a water hole for transporting water and air during drilling.

Material: Made of high-quality alloy materials to ensure good strength and wear resistance.

2、 Size and weight

Length: The length of MF rod R32 can be customized according to actual needs. Common length specifications include 915mm, 1220mm, 1525mm, 1830mm, etc., and can even reach 3660mm or longer.

Diameter: usually 32mm, which is also the origin of the “R32” in its model name.

Weight: MF-Rod R32 of different lengths have different weights. For example, the weight of R32 drill rod with a length of 1100mm is about 6.3kg, while the weight of R32 drill rod with a length of 1220mm is about 7.6kg.

3、 Product advantages

High quality: Made of high-quality alloy materials, ensuring the durability and reliability of the product.

Low price: Compared to other similar products, the MF rad R32 has a higher cost-effectiveness, reducing the purchasing cost for users.

Easy to connect: The threaded design at both ends allows the MF-Rod R32 to be easily connected to other devices or components, improving work efficiency.

High transmission efficiency: The hollow inner hole design enables MF-Rod R32 to effectively transmit water and air during drilling, improving drilling efficiency.

In summary, MF-rod R32 is a high-quality and cost-effective quick connect drill rod widely used in engineering fields such as mining and tunnel construction. If you need more information about MF rod R32 or purchase related products, please consult a professional rock drilling equipment supplier or manufacturer.

4、 Application scenarios

MF rod R32, as a high-quality quick connect drill rod, plays an important role in multiple engineering fields and occasions due to its excellent characteristics and wide applicability. The following are the main applications for MF rod R32:

Mining: In mines, MF rod R32 is often used in conjunction with large hydraulic rock drilling machines for rock drilling operations. Its high strength and wear resistance enable it to work for long periods of time in harsh mining environments, improving mining efficiency.

Tunnel construction: MF-rod R32 also plays an important role in tunnel construction. It can be used in conjunction with tunnel boring machines or other drilling equipment for tunnel excavation and support operations. Its easy to connect feature enables efficient drilling work even in narrow tunnel spaces.

Basic Engineering: In the field of basic engineering, such as bridge and high-rise building foundation construction, MF-rod R32 is also commonly used for foundation reinforcement and drilling operations. Its precise dimensions and high-quality manufacturing process ensure the accuracy and stability of drilling.

Other engineering applications: In addition to the above-mentioned fields, MF-rod R32 can also be used in other situations that require drilling operations, such as engineering construction in water conservancy, hydropower, transportation and other fields.

5、 Advantages and disadvantages of MF rod R32

MF rod R32, as a high-quality quick connect drill rod, has a wide range of applications in the engineering field. Its advantages and disadvantages are as follows:

advantage

High strength and wear resistance: MF-rod R32 is made of high-quality alloy materials, which have high strength and wear resistance, and can work for a long time in harsh engineering environments without being easily damaged.

Easy connectivity: The two ends of the MF rod R32 are designed with threads, making it easy to quickly connect with other devices or components and improving work efficiency. This easy connectivity also makes it convenient for MF-Rod R32 to perform drilling operations in small spaces.

High transmission efficiency: The hollow inner hole design of MF-rod R32 enables effective transmission of water and air during drilling, improving drilling efficiency. This is particularly important for engineering operations that require continuous drilling and cooling.

Widely applicable fields: MF-Rod R32 is suitable for multiple fields such as mining, tunnel construction, and foundation engineering, and has broad application prospects.

shortcoming

The cost may be relatively high: Although MF rad R32 has high quality and wide applicability, its manufacturing cost may be relatively high, resulting in a higher sales price. This may be a consideration factor for some budget limited engineering projects.

There are certain requirements for the usage environment: MF-Rod R32 needs to be used in specific engineering environments, such as mines, tunnels, etc. Using in other non professional environments may result in performance degradation or damage.

Maintenance cost: Although the MF rad R32 has high durability, it still requires maintenance and upkeep after long-term use. This includes checking the wear of the threads, cleaning the inner holes, etc. to ensure their proper functioning.

In summary, MF-Rod R32 has advantages such as high strength, wear resistance, easy connectivity, and a wide range of application fields. However, it also has disadvantages such as high cost, certain requirements for the usage environment, and the need for regular maintenance. When choosing to use MF rad R32, it is necessary to comprehensively consider factors such as the specific requirements and budget of the engineering project.

6、 MF rod R32 link method

1、 Direct threaded connection

The two ends of the MF rod R32 are usually designed with standard external threads, which allows it to be directly connected to other devices or components with corresponding internal threads. This connection method is simple, fast, and has high connection strength. For example, MF rod R32 can be directly connected to drill bits for drilling operations.

2、 Connect using a connector sleeve

When it is necessary to connect two MF rod R32 or other types of drill rods, a corrugated thread connection sleeve can be used for connection. The design of the connecting sleeve enables the two drill rods to be tightly connected together, while ensuring the strength and stability of the connection. This connection method is particularly common in situations such as mining and tunnel construction that require long-term continuous drilling.

3、 Connection with other devices

In addition to the above two connection methods, the MF rad R32 can also be connected to other types of devices through specific connectors or adapters. For example, it can be used in conjunction with hydraulic trolleys, rock drills, and other equipment to achieve automated and efficient drilling operations.

4、 Precautions

When connecting MF rod R32, ensure that the threads are clean and dry to avoid impurities or moisture between the threads that may affect the connection effect.

Appropriate torque should be used for fastening during connection to ensure the firmness and stability of the connection. Tight or loose torque can cause damage or looseness at the connection.

Regularly inspect the wear of the connection points and replace severely worn components in a timely manner to ensure the normal operation and safety of the MF-Rod R32.

In summary, the connection methods of MF-rod R32 mainly include direct threaded connection, use of connecting sleeves for connection, and connection with other devices. These connection methods enable the MF-rod R32 to be flexibly applied in various engineering scenarios, meeting different drilling requirements.

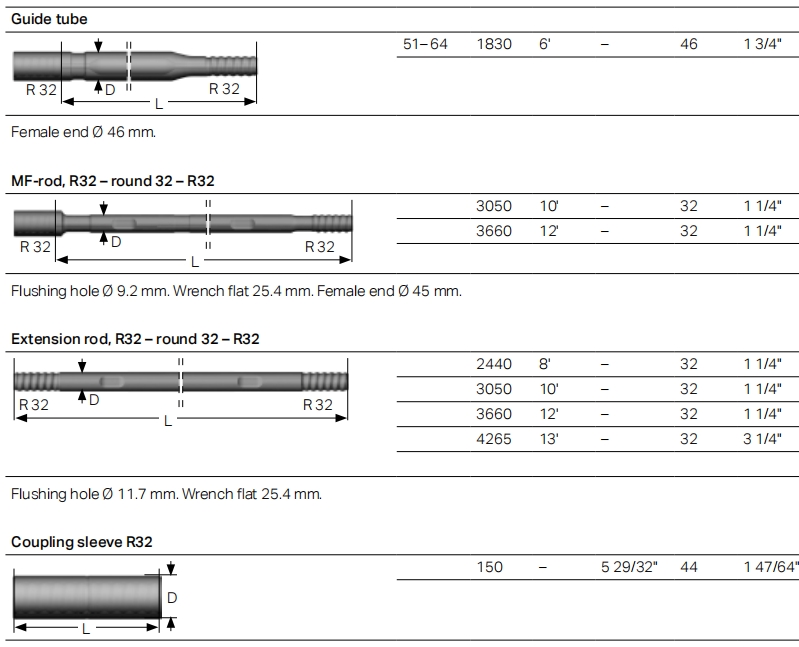

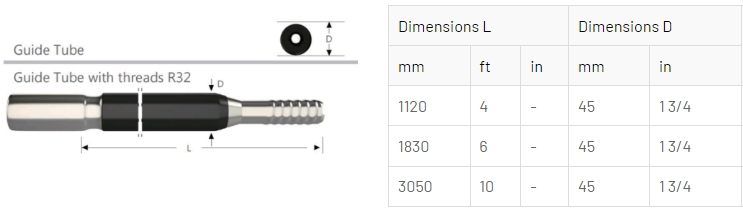

The use of guide tubes in underground deep hole drilling significantly contributes to achieving straighter holes. This not only enhances the drilling efficiency by minimizing deviations and waste, but also substantially reduces the overall operating costs associated with corrections and additional drilling.

When specifying guide tubes and drilling rods, a variety of thread types and sizes are available to cater to different drilling needs:

Thread Types: R32, T38, T45, T51, ST58, GT60, MT60, and ST68, each designed for specific applications and hole diameters.

Diameters (mm): 46, 56, 65, 76, and 87, offering a range of sizes to fit various drilling requirements and geological conditions.

Lengths (mm): 1220, 1525, 1830, 2280, 3050, and 3660, ensuring that the rods can reach the desired depths efficiently while maintaining structural integrity.

Highlights of the Drilling Rods:

Quality Materials and Heat Treatment: The thread ends of the rods are crafted from premium materials and undergo rigorous heat treatment processes. This not only hardens the material, reducing the likelihood of dents in the thread ends but also significantly extends the overall service life of the rods.

Reduced Breakage Risk: The heat treatment and use of high-quality materials also minimize the risk of thread end breakage. This ensures a smoother drilling operation with minimal interruptions and downtime.

Enhanced Durability and Efficiency: With less wear on the outer and inner sides of the rod ends, the rods maintain their threading integrity over extended periods. This reduces the need for frequent replacements and increases both use efficiency and service life.

Tight Tolerance for Safety and Durability: The rods are manufactured to precise tolerances, ensuring a snug fit and minimizing the potential for failures due to improper threading. This tight tolerance guarantees not only the safety of the drilling operation but also the durability and high quality of the final hole.

In summary, the combination of guide tubes and high-quality, precisely engineered drilling rods with a variety of thread types, diameters, and lengths ensures straighter holes, higher efficiency, cost savings, and long-term durability in underground deep hole drilling operations.

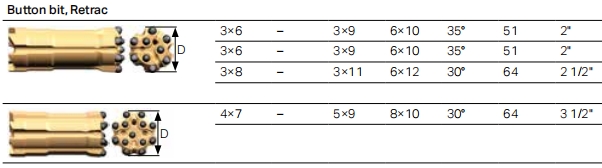

Retrac button bits are a type of drilling tool commonly used in the mining and construction industries. These button bits are designed with a retractable skirt feature, which helps in retrieving the drill tool from loose and relatively broken rock masses. The retractable skirt design reduces the risk of bit sticking and burial, and it also aids in improving the straightness of the borehole.

These button bits are available in various sizes and specifications to cater to different drilling requirements. They are manufactured with high-quality materials and carbide tips to ensure durability and efficient performance. The table provided in the knowledge base offers a detailed list of retrac button bits, including their appearance, diameter, button configuration, flushing hole details, and weight.

Some common models of retrac button bits include R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, and SR35. Each model has specific dimensions and features that make them suitable for particular drilling applications. For example, the T45 retrac button bit has a diameter of 45mm and is designed for use in medium to hard rock formations.

In summary, retrac button bits are specialized drilling tools that offer improved retrieval capabilities and better borehole straightness, making them ideal for use in challenging drilling conditions.

January 11, 2024

January 11, 2024