Extended drilling tools are usually used in drilling areas that require deep drilling or are difficult to reach directly. They increase the length of the drill rod, allowing drilling tools to reach farther or deeper positions. This type of drilling tool has a wide range of applications in fields such as petroleum, natural gas, geological exploration, and mining.

HANDHELD AND SMALL HOLE DRILLING

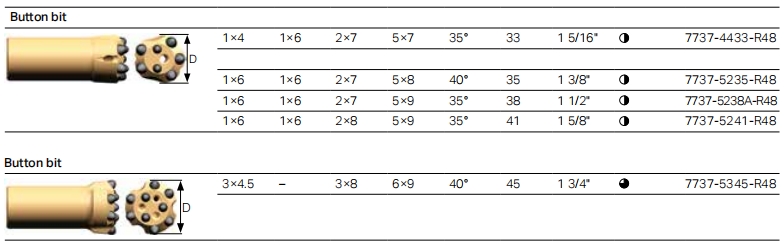

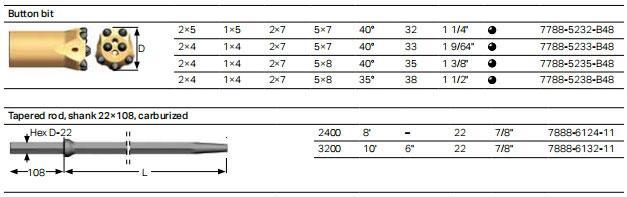

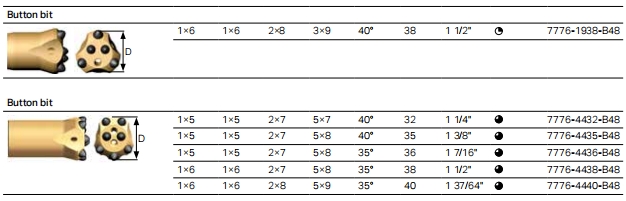

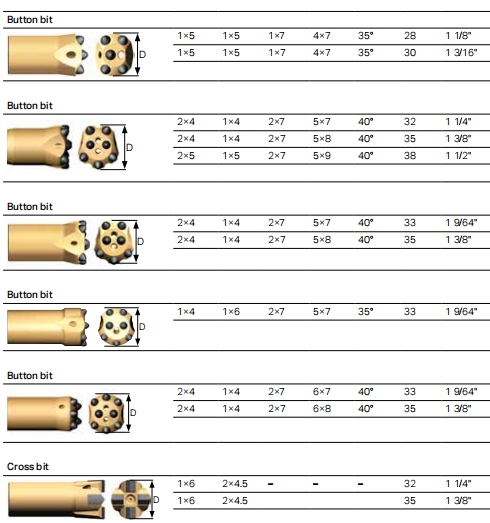

Button bit

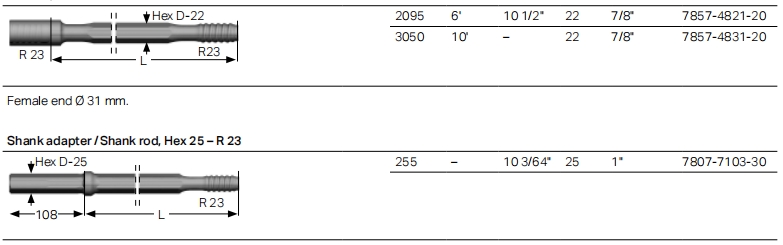

MF-rod, R23 – Hex 22 – R23

The extension drill rod serves as a conduit for transferring power from the rock drill piston to the rock surface. One end of this rod attaches to a coupling or shank adapter, while the opposite end connects to a threaded drill rod.

Specifications:

Key Features:

Usage:

Ideal for drilling tasks in tunneling, construction projects, mining operations, quarrying activities, and other similar applications.

Bench and Production Rods, Extension Rods, MF(Speed) Rods |

| Description | Length | Diameter | Weight | ||

| mm | feet | mm | inch | kg | |

| Extension RodR32 – Round32 – R32 | 2435 | 8′ | 32 | 1 1/4” | 14.20 |

| 3050 | 10′ | 32 | 1 1/4” | 17.80 | |

| 3660 | 12′ | 32 | 1 1/4” | 21.30 | |

| MF (Speed) RodR32 – Round32 – R32 | 3050 | 10′ | 32 | 1 1/4” | 17.90 |

| 3660 | 12′ | 32 | 1 1/4” | 21.45 | |

| 4270 | 14′ | 32 | 1 1/4” | 25.10 | |

| Extension RodR38 – Round39 – R38 | 3050 | 10′ | 39 | 1 17/32” | 25.50 |

| 3660 | 12′ | 39 | 1 17/32” | 30.60 | |

| 4270 | 14′ | 39 | 1 17/32” | 35.40 | |

| MF (Speed) RodR38 – Round39 – R38 | 3050 | 10′ | 39 | 1 17/32” | 26.50 |

| 3660 | 12′ | 39 | 1 17/32” | 31.60 | |

| 4270 | 14′ | 39 | 1 17/32” | 36.40 | |

| Extansion RodT38 – Round39 – T38 | 3050 | 10′ | 39 | 1 17/32” | 25.50 |

| 3660 | 12′ | 39 | 1 17/32” | 30.60 | |

| 4270 | 14′ | 39 | 1 17/32” | 35.40 | |

| MF (Speed) RodT38 – Round39 – T38 | 3050 | 10′ | 39 | 1 17/32” | 26.50 |

| 3660 | 12′ | 39 | 1 17/32” | 31.60 | |

| 4270 | 14′ | 39 | 1 17/32” | 36.40 | |

| Extension RodT45 – Round46 – T45 | 3050 | 10′ | 46 | 1 3/4” | 35.80 |

| 3660 | 12′ | 46 | 1 3/4” | 43.00 | |

| 4270 | 14′ | 46 | 1 3/4” | 50.10 | |

| MF (Speed) RodT45 – Round46 – T45 | 3050 | 10′ | 46 | 1 3/4” | 36.40 |

| 3660 | 12′ | 46 | 1 3/4” | 43.70 | |

| 4270 | 14′ | 46 | 1 3/4” | 50.70 | |

| Extension RodT51 – Round52 – T51 | 3660 | 12′ | 52 | 2” | 54.20 |

| 4270 | 14′ | 52 | 2” | 63.50 | |

| MF (Speed) RodT51 – Round52 – T51 | 3660 | 12′ | 52 | 2” | 55.70 |

| 4270 | 14′ | 52 | 2” | 64.80 | |

| Extension RodR32 – Round32 – R32 | 915 | 3′ | 32 | 1 1/4” | 5.50 |

| 1220 | 4′ | 32 | 1 1/4” | 7.32 | |

| 1525 | 5′ | 32 | 1 1/4” | 9.18 | |

| 1830 | 6′ | 32 | 1 1/4” | 10.95 | |

| MF (Speed) RodR32 – Round32 – R32 | 915 | 3′ | 32 | 1 1/4” | 5.45 |

| 1220 | 4′ | 32 | 1 1/4” | 7.28 | |

| 1525 | 5′ | 32 | 1 1/4” | 9.10 | |

| 1830 | 6′ | 32 | 1 1/4” | 10.72 | |

| Extension RodT38 – Round39 – T38 | 1220 | 4′ | 39 | 1 17/32” | 9.20 |

| 1525 | 5′ | 39 | 1 17/32” | 10.25 | |

| 1830 | 6′ | 39 | 1 17/32” | 15.30 | |

| MF (Speed) RodT38 – Round39 – T38 | 1220 | 4′ | 39 | 1 17/32” | 9.50 |

| 1525 | 5′ | 39 | 1 17/32” | 11.25 | |

| 1830 | 6′ | 39 | 1 17/32” | 16.30 | |

| MF (Speed) RodT45 – Round46 – T45 | 1525 | 5′ | 46 | 1 3/4” | 18.50 |

| 1830 | 6′ | 46 | 1 3/4” | 22.20 | |

| MF (Speed) RodT51 – Round52 – T52 | 1525 | 5′ | 52 | 2” | 17.85 |

| 1830 | 6′ | 52 | 2” | 28.10 | |

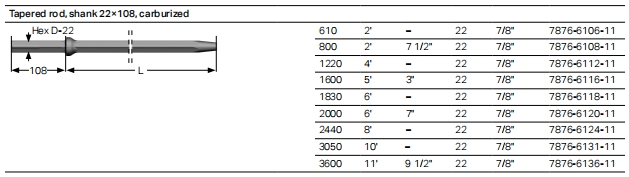

Connected at one end to a rock drill and at the other to a taper drill bit, the taper drill rod serves as the conduit for transmitting power, enabling the drill bit to perform its work. An advanced version of integral drill rods, the tapered drill rod typically features a forged collar that ensures the shank maintains the correct striking face position within the rock drill. The effective length of the tapered drill rod, measured from the collar to the bit end, typically ranges from 0.6 meters to 3.6 meters.

Parameters:

Features:

The Fully-Carburized Taper Drill Rod undergoes a carburization process to enrich its surface carbon content, significantly boosting both its surface hardness and overall structural strength. This enhancement extends the service life of the taper drill rod. In comparison to traditional taper drill rods, the Fully-Carburized version excels in strength and abrasion resistance. Within similar industrial and mining applications, its lifespan surpasses that of standard taper drill rods by several folds.

Available taper degrees include: 4°46’, 6°, 7°, 11°, and 12°.

Shank specifications offered are: Hex.19mm, Hex.22mm, and Hex.25mm.

Beyond offering standard drill rod lengths, our company provides customized lengths tailored to meet our clients’ specific requirements.

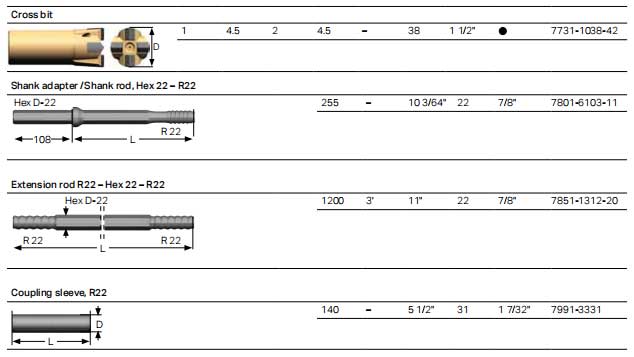

R22 (7/8 “) Extension Drilling TOOLS, also known as R22 series 7/8 inch extension drilling tools, is a professional drilling equipment.

The taper drill rod H22 7° TAPER is a tool that connects one side to the rock drill and the other side to the taper drill bit. It transmits power from the rock drill to the bit, enabling drilling work to be performed.

Parameters of the taper drill rod include:

Rock drill connection: H22*108mm

Conical degree options: 4°46′, 6°, 7°, 11°, 12°

Length range: 400mm-8000mm

Among these parameters, the conical degree of 7° is specifically mentioned in the query “H22 TAPERED TOOLS, 7° TAPER”.

DTH drill pipe (Down The Hole Drill Pipe), also known as down-the-hole drill pipe, is a key component in drilling equipment and plays an important role in rock or concrete drilling operations in mining, construction, geological exploration and other fields. The following is a detailed introduction to DTH drill pipe:

1.Structure and composition

DTH drill pipe is usually connected by multiple pipes, and the internal channel is used to transmit compressed air or liquid to provide energy to drive the DTH hammer. The DTH hammer is located at the bottom of the drill pipe. It uses the energy of compressed air or liquid to generate high-frequency impact force, hit the drill bit, and transfer energy to the rock. At the same time, the drill pipe drives the drill bit by rotating, so that it rotates in the rock and breaks the rock.

2.Working principle

The working principle of DTH drill pipe is mainly based on impact and rotation. When the DTH hammer is pushed by compressed air or liquid, it generates a high-frequency impact force, hits the drill bit, and transfers energy to the rock. This impact force enables the drill bit to penetrate deep into the rock and break the rock. At the same time, the drill pipe drives the drill bit by rotating, causing it to rotate in the rock, further breaking the rock and forming a borehole.

3.Features and Advantages

High Efficiency: DTH drill pipe adopts DTH drilling technology, which can complete deep hole drilling tasks in a shorter time and improve drilling efficiency.

Strong adaptability: DTH drill pipe is suitable for various geological conditions, including hard rock, soft rock, coal seam, etc., and can meet different drilling needs.

Good durability: DTH drill pipe is made of high-strength material, has high wear resistance and corrosion resistance, and can be used for a long time in harsh working environment.

4. Application and Field

DTH drill pipe is widely used in many fields, including but not limited to:

Construction field: DTH drill pipe can be used for foundation drilling, bridge foundation drilling, etc. in building foundation engineering.

Mining field: In the mining industry, DTH drill pipe can be used for mine exploration, mine support and other operations.

Geological exploration field: DTH drill pipe can be used for core drilling, groundwater exploration, etc. in the geological exploration industry.

5.Maintenance and care

In order to ensure the long-term stable operation of DTH drill pipe, regular maintenance and care are required. This includes cleaning the dirt inside and outside the drill pipe, checking the wear of the drill pipe, replacing severely worn parts, etc. In addition, attention should be paid to the storage environment of the drill pipe to avoid it from being affected by factors such as moisture and corrosion.

In summary, DTH drill pipe, as a high-efficiency, adaptable and durable drilling equipment component, plays an important role in many fields. By understanding its structure and composition, working principle, characteristics and advantages, and application and field knowledge, DTH drill pipe can be better selected and used to meet the needs of different drilling operations.

The T51 drill rod is a specialized drilling tool featuring a T51 thread connection at its terminal end, enabling the attachment of drill bits specifically for underground rock drilling operations. The design of this drill bit takes into account the need for durability and reliability in high-strength rock conditions, ensuring smooth and uninterrupted drilling processes. Its structural design and choice of materials are tailored to endure harsh operational environments, including high pressure, elevated temperatures, and high-frequency vibrations, thereby guaranteeing the safety and efficiency of drilling activities.

Details about T51 Drill rod

Specifications:

| Thread Type | T51 |

| Drill rod body shape | Round |

| Specification | T51-3660-MM,T51-4270-MM,T51-6095-MM,T51-3050-MF,T51-3660-MF,T51-4270-MF,T51-4600-MF,T51-6095-MF |

| Raw material | 23CrNi3Mo |

In South Africa, the Reverse Circulation DTH Drill Bit has also received widespread attention and application as an efficient drilling tool. The following is a detailed explanation of its application and characteristics in South Africa:

1、 Application background

South Africa is a country rich in mineral resources, with a wide variety of mineral resources including gold, diamonds, platinum group metals, and more. The extraction and exploration of these mineral resources require efficient and reliable drilling tools. The reverse circulation pneumatic down the hole hammer drill bit has played an important role in mineral exploration and mining in South Africa with its unique drilling method and efficient drilling efficiency.

2、 Application features

Efficient drilling: The reverse circulation pneumatic down the hole hammer drill bit uses compressed air as a power source to break rocks through high-frequency impact force, resulting in fast drilling speed and high efficiency. This drilling method is particularly prominent in hard rock formations in South Africa, and can significantly improve drilling efficiency.

Continuous slag discharge: By using a reverse circulation method, rock debris can be continuously discharged outside the hole, avoiding blockage and repeated crushing inside the hole. This feature is particularly important in mineral exploration in South Africa, as blockage in the borehole can seriously affect drilling progress and efficiency.

Strong adaptability: The reverse circulation pneumatic down the hole hammer drill bit is suitable for various formations and rock types, including hard rock, soft rock, etc. In the complex geological formations of South Africa, this drill bit can demonstrate good adaptability and drilling performance.

Easy to operate: The drill bit has a compact structure, is easy to operate, and is easy to maintain and replace. This reduces the operational difficulty and cost during the drilling process, and improves the overall efficiency of the drilling operation.

3、 Application Fields

In South Africa, reverse circulation pneumatic down the hole hammer drill bits are mainly used in the following fields:

Mineral exploration: used to extract core samples and provide reliable basis for the exploration and development of mineral resources. In mineral exploration in South Africa, this drill bit can efficiently and accurately obtain core samples, providing strong support for the assessment and development of mineral resources.

Water well construction: used for rapid drilling and improving the efficiency of water well construction. In arid regions of South Africa, well construction is crucial for the livelihoods and agricultural production of local residents. The reverse circulation pneumatic down the hole hammer drill bit can quickly form water well channels, providing clean and safe water sources for local residents.

Anchor engineering construction: used to quickly form anchor holes and provide strong support for the installation of anchor rods. Anchor engineering is a common construction method in infrastructure construction in South Africa. The reverse circulation pneumatic down the hole hammer drill bit can quickly and accurately form anchor holes, providing a solid foundation for the installation of anchor rods.

4、 Development Trends

With the continuous development of mineral resources and advances in exploration technology in South Africa, the application prospects of reverse circulation pneumatic down the hole hammer drill bits in South Africa will be even broader. In the future, its development trend may include the following aspects:

Technological innovation: Through continuous technological innovation and improvement, the drilling efficiency, adaptability, and service life of drill bits are improved. For example, adopting more advanced materials and manufacturing processes, optimizing the structure of drill bits and the design of cutting edges, etc.

Intelligent control: Utilizing modern sensors and intelligent control technology to achieve real-time monitoring and intelligent control of drilling. This can improve the accuracy and safety of drilling, reduce operational difficulty and costs.

Environmental protection and energy conservation: With the increasing global attention to environmental protection and energy conservation issues, reverse circulation pneumatic down the hole hammer drill bits also need to develop towards a more environmentally friendly and energy-saving direction. For example, adopting more efficient compressed air utilization methods to reduce energy consumption and emissions.

In summary, reverse circulation pneumatic down the hole hammer drill bits play an important role in mineral exploration, water well construction, and anchoring engineering construction in South Africa. In the future, with the continuous advancement and innovation of technology, its application prospects will be even broader.

About the characteristics and applications of H22 Tapered Tools and its 11° Taper

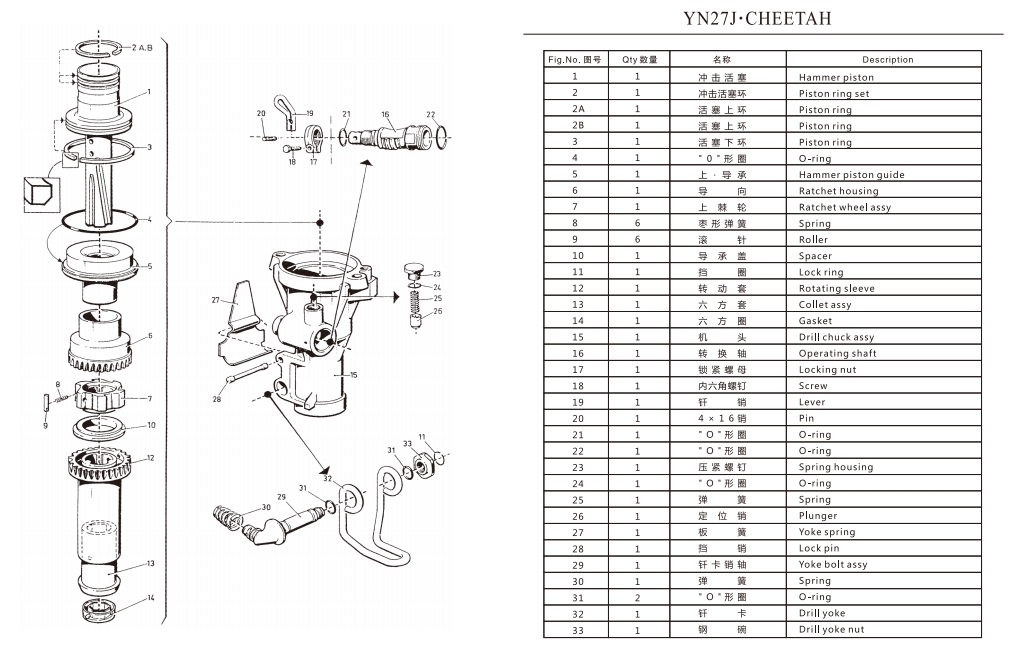

YN27C has a wide variety of spare parts, covering various components required from basic maintenance to deep repairs. Here are some common YN27C spare parts and their related information:

1、 Main spare parts

Piston ring

Importance: The piston ring is a critical component in internal combustion engines, used to seal the combustion chamber and prevent gas leakage.

Price range: Prices may vary depending on the supplier and bulk purchase situation. For example, the unit price of piston rings provided by some suppliers may range from $2.30 to $2.90, and the minimum order quantity is usually 10 pieces.

Ignition coil

Importance: The ignition coil is the core component of the internal combustion engine ignition system, responsible for generating high-voltage electric sparks to ignite the mixture.

Price range: generally between $14.60 and $15.00, depending on the purchase quantity and supplier.

Oil needle component

Importance: The fuel needle component is used to regulate the fuel supply of the internal combustion engine, ensuring stable operation of the engine.

Price range: Typically between $7.20 and $7.80, the specific price may vary depending on the supplier and purchase quantity.

Sealing ring

Importance: The sealing ring is used to ensure the sealing between various components of the internal combustion engine and prevent gas and liquid leakage.

Price range: The unit price may be between $1.20 and $1.80, and typically requires a minimum order quantity of 10 pieces.

piston

Importance: The piston is a key moving component in internal combustion engines, responsible for converting the energy generated by combustion into mechanical energy.

Price range: For example, the unit price of aluminum pistons may range from $4.50 to $4.90 (with a minimum order quantity of 10 pieces).

2、 Other spare parts

In addition to the main components mentioned above, YN27C may also involve the following components:

spark plug

Used for igniting combustible mixtures, it is an important component of the ignition system of internal combustion engines.

Ratchet and spring

These components are typically used in the transmission and reset mechanisms of internal combustion engines.

Connect the wedge plug and bolt

Used to connect various components of the internal combustion engine, ensuring the overall structural stability of the engine.

skull

One of the important components of an internal combustion engine, used to protect the internal structure of the engine.

Electric disc

One of the electrical components of an internal combustion engine, responsible for providing power and signal transmission.

3、 Purchase advice

Choose a reliable supplier: When purchasing YN27C spare parts, be sure to choose a supplier with a good reputation and reliable quality assurance.

Confirm product specifications: Before purchasing, be sure to confirm the specifications and models of the required spare parts to ensure compatibility with your device.

Compare prices and services: Before purchasing, you can compare prices and services from different suppliers and choose the most cost-effective solution.

In summary, YN27C has a wide variety of spare parts, covering various key components of internal combustion engines. When purchasing, it is important to choose a reliable supplier and confirm product specifications and prices.

In terms of connection strength and service life, brazing is generally considered to be the best method for connecting tungsten carbide buttons to roller bits. The following is a detailed comparison of the connection strength and service life of the three methods:

Connection Strength

Brazing method:

The metallurgical bonding between the tungsten carbide button and the drill bit base is achieved by melting the brazing material at high temperature.

The connection strength is high and can withstand large drilling forces and torques.

The joint is dense and complete, with good performance, and the high-temperature tensile strength can reach 60% or even higher than the parent material strength.

Mechanical pressing method:

The tungsten carbide button is pressed into the reserved hole in the drill bit base by mechanical force.

The connection strength is moderate, but may be affected by the accuracy of the pressing tool and equipment.

Under long-term high-load operation, the connection may become loose or worn.

Adhesive method:

The tungsten carbide button is bonded to the drill bit base by using a specific adhesive.

The connection strength is relatively low and mainly depends on the strength and durability of the adhesive.

In harsh drilling environments, the adhesive may fail due to aging, corrosion, etc.

Service life

Brazing method:

Due to the high connection strength, it can withstand long-term drilling operations without loosening or falling off.

The joint has good heat resistance and corrosion resistance, and can maintain stable performance in harsh drilling environments.

Therefore, the service life of the brazing method is usually longer, which can meet the needs of high-intensity operations such as deep well drilling and hard rock drilling.

Mechanical pressing method:

The service life is affected by the connection strength and the accuracy of the pressing tool.

Under long-term high-load operation, the connection may become loose or worn, resulting in a shortened service life.

Adhesive method:

The service life mainly depends on the strength and durability of the adhesive.

In harsh drilling environments, the adhesive may fail due to aging, corrosion, etc., resulting in a shorter service life.

In summary, the brazing method performs best in terms of connection strength and service life. However, the specific method to be selected still needs to be comprehensively considered based on drilling needs, cost budget and production conditions. In practical applications, the most suitable insertion method should be selected according to the specific situation to ensure the performance and life of the drill bit.

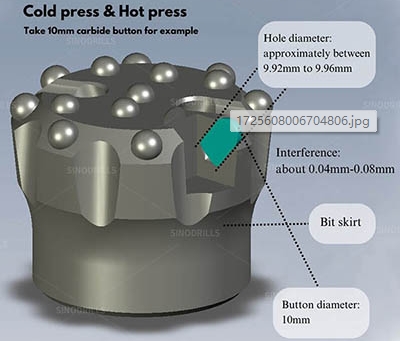

Button bits demonstrate their unique superiority in mining, quarrying, water wells, construction, and other areas. The carbide buttons inserting of button bit is crucial, being a significant factor affecting the quality and lifespan of the button bit.

There are three methods for inserting carbide buttons: copper brazing, cold press, and hot press.

1. Copper Brazing

Copper brazing is the earliest way of inserting carbide buttons, primarily determining the size of the hole and the carbide button based on the gap during brazing. According to the bit skirt structure, corresponding button holes are drilled into the bit skirt, and then the carbide buttons are welded into the bit skirt using copper or silver welding techniques.

This method does not require high precision for the drilling or button size. During brazing, the brazing material is placed at the bottom of the carbide button, with some flux sprinkled on the carbide button surface. The brazing material diffuses fully in an oxygen-free condition, forming a dense, uniform, and full weld. The hole only bears the radial and tangential stresses caused by the condensation shrinkage of the weld, with no axial tensile or compressive stress. Additionally, this layer of brazing material can delay the impact during rock drilling, thus avoiding the disadvantages of interference fit.

However, the high temperatures during welding impose thermal stresses, potentially causing defects and micro-crack propagation in the low cobalt alloy, as well as reduced hardness (by HRC 0.5-0.8 ) and bending strength (by 8%-20%) of the carbide. The formation of an oxide layer on the surface of the alloy button makes the carbide button prone to fracture.

Currently, this method is mainly used for single used button bits, such as blast furnace tapping bits and anchor bits.

2. Cold Press V.S Hot Press

Cold press and hot press both utilize interference fit to fix the carbide buttons, and the interference is generally between 0.04mm and 0.08mm. Factors influencing the interference include, but are not limited to:

1. Drill bit skirt material;

2. Heat treatment process of the skirt;

3. Diameter of the carbide buttons;

4. The equipment for inserting carbide buttons into the bit skirt.

Cold press is done at room temperature, without the need to heat the button bit, directly using a hydraulic hammer to press the carbide buttons firmly into the button bit.

This process has a lower production cost but lacks stability.

Improper selection of interference can significantly increase the pressing force, sometimes causing the carbide and the hole to be damaged. Even with appropriate interference, the tangential, axial, and radial stresses experienced by the carbide button under heavy loads can accelerate the expansion of existing defects, leading to premature damage to the carbide buttons.

The overall lifespan of cold pressed button bits is limited, particularly in the late drilling stage of button bits, and issues such as buttons popping out or breakage are common.

Cold pressed button bit is generally used for softer, less abrasive rock formation, and higher-end anchor bits often utilize this method.

Unlike cold press, the hot press process takes advantage of the principle of thermal expansion and contraction. It involves heating the bit skirt to a certain temperature, typically between 200°C and 500°C, to expand the diameter of the button holes. Then, the carbide button is inserted into the hole and physically contracted to tightly integrate the buttons with the bit skirt.

This method does not necessitate pressure, or only minimal pressure, thereby avoiding or reducing the impact on the performance of the carbide buttons, making it more effective in maintaining the original properties of the carbide buttons.

Hot press is currently the best and mainstream method for inserting carbide buttons. Hot pressed button bits have better wear resistance, higher hardness, and superior stability, suitable for very hard and highly abrasive rock formation.

As the leading exporter of rock drilling tools in China, Sinodrills’ threaded button bits and down-the-hole button bits are all hot pressed, offering long service life, greater wear resistance, and excellent stability!

HANDHELD AND SMALL HOLE DRILLING

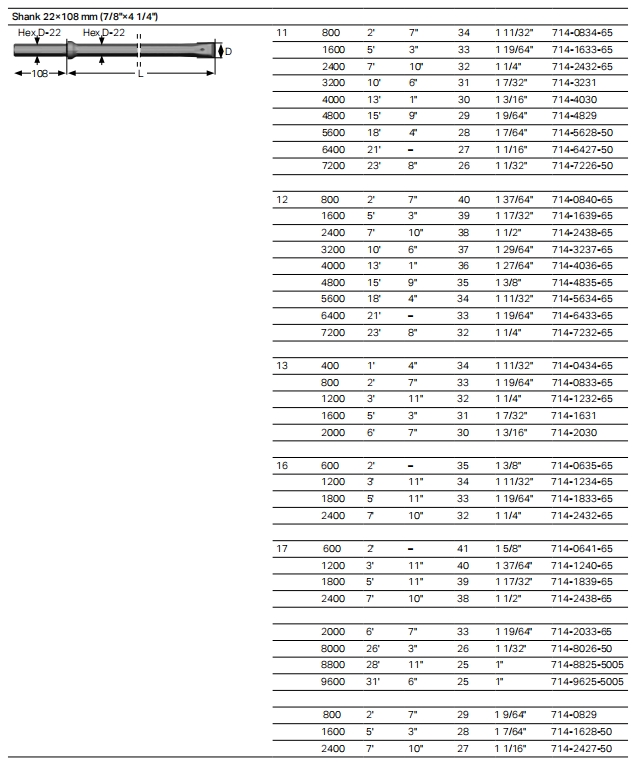

H22 TAPERED TOOLS, 12° TAPER

Taper drill bits are connected to taper drill rods for drilling duties, suitable for tunneling, construction, mining, quarrying, etc.

Parameters

Preventing the failure of threaded drill pipe is a comprehensive process involving multiple aspects, which can be mainly started from the following aspects:

H22 (7/8″) INTEGRAL DRILL STEELS are designed for handheld and small hole drilling applications. These drill steels are commonly used in various industries such as mining, quarrying, and construction. The H22 refers to the size of the drill steel, which has a diameter of 7/8 inches (approximately 22 mm). They are available in different lengths and bit diameters to suit various drilling needs.