Integral drill steels are commonly used in underground mining and small-hole drilling operations. They are often paired with low-power rock drills, such as air-leg or hand-held rock drills. The integrated design helps to reduce the loss of impact energy, thereby improving the speed and efficiency of rock drilling.

The specifications for H19 (3/4) integral drill steels typically include details such as the shank size, length, bit diameter, and weight. These tools are available in various lengths and bit diameters to suit different drilling requirements. The use of high-quality materials and advanced manufacturing techniques ensures their durability and performance in demanding drilling conditions.

HANDHELD AND SMALL HOLE DRILLING-H19 (3/4″) INTEGRAL DRILL STEELS

BIT DIAMETER NOTES

All bit diameters are larger than the given dimensions in the catalog.

Cross bits: Can be a maximum of +1 mm due to manufacturing tolerance.

Button bits: Some bit designs can be a maximum +3 mm to compensate for fast diameter wear.

The minimum diameter for all button bits is +1.5 mm above the given dimensions.

Keep in mind that a bit always drills a bigger hole than the stated bit diameter.

Small-diameter rock drilling tools mainly include a series of equipment and accessories specially designed for drilling small-diameter holes in rock.These tools are usually high-precision, high-efficiency and capable of adapting to different rock types.The following are the main components of small-diameter rock drilling tools:

button bit:

Diamond drill bit: It is commonly used for hard rock drilling and can effectively penetrate various rocks due to its high hardness and wear resistance.There are various types of diamond drill bits, including surface-mounted diamond drill bits and impregnated diamond drill bits. The appropriate type should be selected based on the rock hardness and drilling requirements.

Hard alloy drill bit: suitable for drilling medium-hard to hard rock, although its hardness is slightly inferior to diamond, it has advantages in terms of cost and applicability.

Drill rod:

Drill pipe is a key component that connects the drill bit and the drill rig, responsible for transmitting torque and axial pressure to the drill bit.The drill rods commonly used in small-diameter rock drilling include hexagonal hollow drill rods, which have sufficient strength and rigidity to ensure the stability and efficiency of the drilling process.

Drilling rig:

Small-diameter rock drilling rigs are the core equipment for drilling operations, and can be divided into pneumatic drilling rigs, hydraulic drilling rigs, and electric drilling rigs according to different power sources.These rigs are usually lightweight and easy to operate, and are equipped with precise control systems to achieve accurate drilling positioning and depth control.

Auxiliary equipment:

Including water pumps, air compressors, mud pumps, etc., used to provide cooling, flushing, and lubricating media required during drilling.These devices are crucial for maintaining the good working condition and extending the service life of the drill bit.

Control system:

Modern small-diameter rock drilling tools are usually equipped with advanced control systems that monitor various parameters (such as torque, pressure, speed, etc.) during drilling, and adjust drilling strategies based on real-time data to improve drilling efficiency and safety.

Safety device:

Including overload protection devices, anti-sticking devices, etc., which are used to stop the equipment and protect personnel safety in case of abnormal conditions during drilling.

Accessories and consumables:

Such as replacement parts for worn drill bits, drill rod connectors, seals, etc. The timely replacement of these accessories and consumables is important for maintaining the good performance and extending the service life of drilling tools.

In summary, small-diameter rock drilling tools are a complex system, including drill bits, drill pipes, drilling rigs, auxiliary equipment, control systems, safety devices, and accessories and consumables.These tools work together to achieve efficient, accurate and safe rock drilling operations.

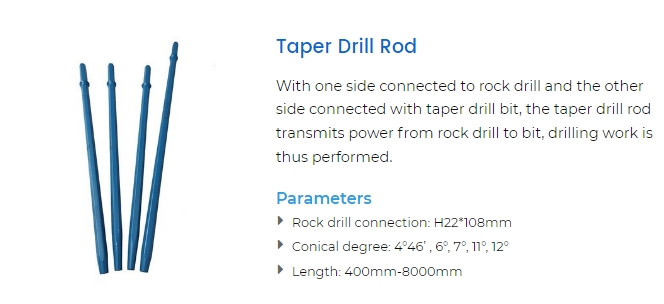

H22*108 Tapered Drill Rod is a type of drill rod commonly used in various industries, particularly in mining, quarrying, and tunneling. The “H22” refers to the diameter of the rod, which is 22 millimeters, while “108” refers to the length of the rod, which is 108 millimeters. The term “tapered” indicates that the rod has a conical shape, with one end being wider than the other, allowing for better penetration and stability when drilling.

These drill rods are designed to be used with rock drill bits and are compatible with jackhammers and other drilling equipment. They are typically made from high-quality steel to ensure durability and resistance to wear and tear. The tapered design helps in reducing vibrations and provides a secure fit with the drill bit, ensuring efficient drilling operations.

Gauge Wear on Button Bits

When drilling through materials like hard sandstone and quartzite, the wear on the bit circumference tends to be more pronounced. Most of this wear occurs on the outer buttons located at the periphery, causing the bits to round off around their circumference. Consequently, when the buttons are sharpened, the diameter across the gauge buttons becomes smaller than that of the bit shoulders, leading to a tendency for the bit to bind within the hole. To rectify this and restore adequate clearance, the circumference of the bit shoulder must be ground down. Additionally, the bit face often requires grinding to restore the protrusion of the buttons.

Body Wash of Button Bits

In non-abrasive materials where carbide wear is minimal, extended drilling intervals are feasible. This allows for prolonged chip removal around the bits, resulting in more wear on the bit body compared to the buttons. Similar wear patterns are observed in fractured and loose materials, where excessive agitation and grinding are necessary for hole cleaning and maintaining an open hole during retraction. To prevent button tear-outs and shearing under these conditions, it’s crucial to schedule grinding intervals to reduce button protrusions.

Over Drilling Consequences

The detrimental effects of over drilling bits may not be immediately evident, but they are significant. A commonly overlooked fact is that using dull bits not only slows down drilling rates but also significantly increases drilling costs by shortening the lifespan of drilling tool components, rock drills, and drill rig parts. Over drilling is unquestionably responsible for over 90% of all premature button failures. However, it is well-documented that eliminating over drilling and performing proper sharpening significantly reduces premature button bit insert failures.

Our shank and drill bits are carefully manufactured, strictly tested and officially approved to ensure their perfect compatibility with your Atlas Copco drill bits. These products are equipped with R25 threaded drill bits, which have a wide range of diameters ranging from 33 millimeters to 51 millimeters. More importantly, all of our drill rods and drill bits are made of extremely durable steel, which not only has excellent wear resistance but also unparalleled anti-corrosion ability, significantly extending the service life of our products.

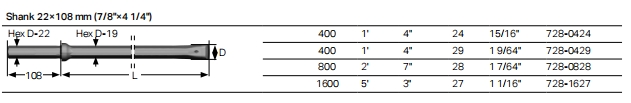

Shank hex. 22 mm (7/8″) x 108 mm (4 1/4″). Rod hex. 22 mm (7/8). Flushing hole diameter 6.7 mm

Product no. Product code Length Weight approx.

mm foot/inch kg

4º46′ taper angle

90510626 578-0108,11 800 2’7½” 2,8

90510627 578-0116,11 1600 5’3″ 5,3

90510628 578-0120,11 2 000 6’6¾” 6,5

90510629 578-0124,11 2 400 7’10½” 7,7

90510630 578-0132,11 3 200 10’6″ 10,2

90513835 578-0135,11 3 500 11’5¾” 11,1

90510631 578-0140,11 4 000 13’1½” 12,7

7º taper angle

90513772 573-0104,11 400 1’3¾” 1,6

90505067 573-0108,11 800 2’7½” 2,8

90504826 573-0116,11 1 600 5’3″ 5,2

90504827 573-0118,11 1 830 6′ 6,0

90504756 573-0120,11 2 000 6’6¾” 6,5

90504828 573-0124,11 2 435 8′ 7,8

90515483 573-0124-C,02 2 435 8′ 7,8

90504829 573-0131,11 3 050 10′ 9,7

90504831 573-0132,11 3 200 10’6″ 10,1

90516583 573-0132-C,02 3 200 10’6″ 10,1

90514346 573-0136,11 3 600 12′ 11,4

90513773 573-0140,11 4 000 13’1½” 12,6

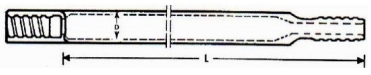

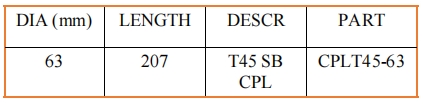

T45 Extension Rod is a professional tool used in fields such as coal mining, tunnel excavation, and long hole drilling. The following is a detailed introduction about T45 Extension Rod:

Mainly used for drift and tunnel excavation in coal mining.Suitable for long hole drilling, such as drilling on workbenches.

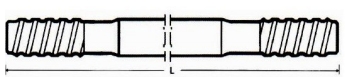

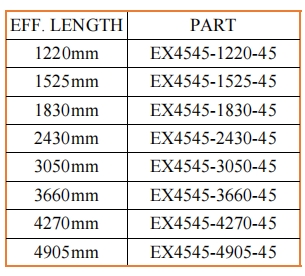

RODS T45 HEX 38mm

RODS T45ROUND 45mm

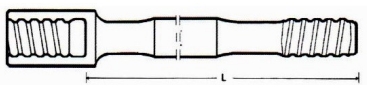

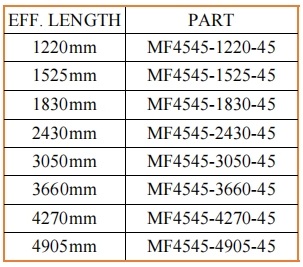

MF RODS T45 ROUND 45mm

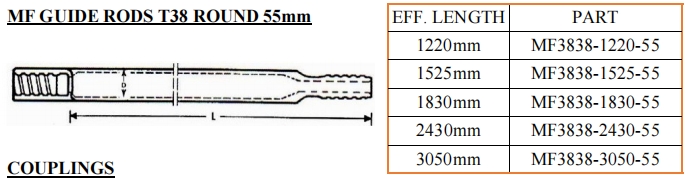

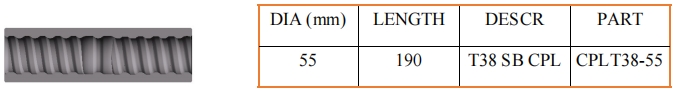

MF GUIDE RODS T38 ROUND 55mm

T38 64mm thread button drill bits are made by high quality alloy steel bar. Through heat treatment, our drilling tools are tough enough to meet rock drilling demands and have the least loss of energy while drilling the rocks.

Besides, Shandike can design customized thread button drill bits according to different drilling application, and custom drill bits are applicable to drill soft rock, loose-medium rock and hard rock.

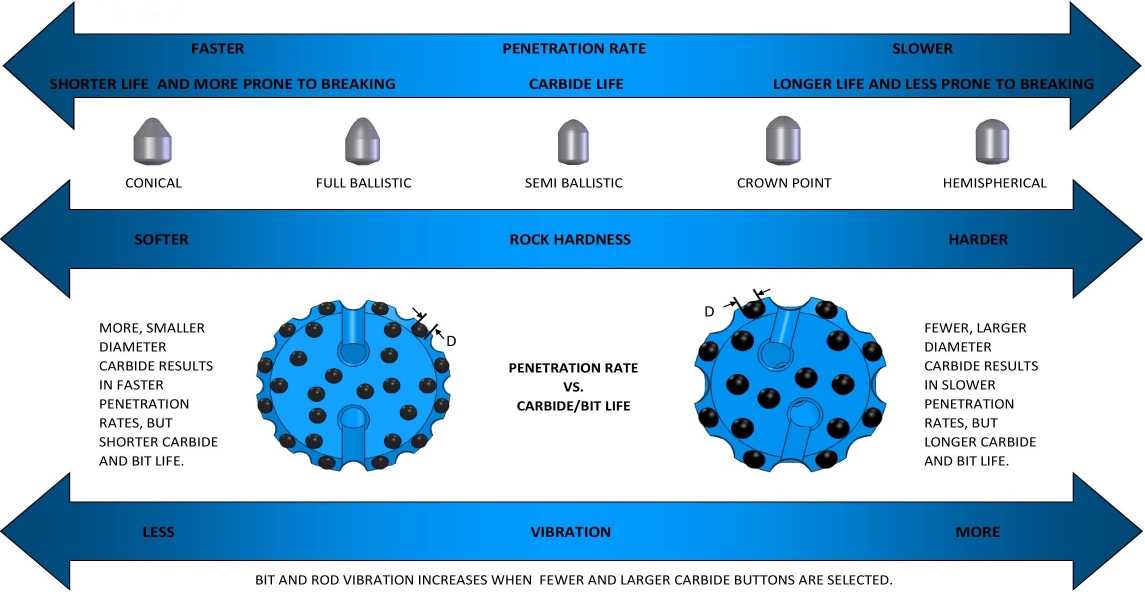

Less buttons but bigger buttons:

It has relatively lower penetration rate, but the carbide is not easy to wear, so it has longer life span.It is for soft, medium hard and low abrasve rock formation.

More buttons but smaller buttons:

It has higher penetration rate, but the carbide is easy to wear, so it has longer life span.

It is for very hard and high abrasive rock formation.

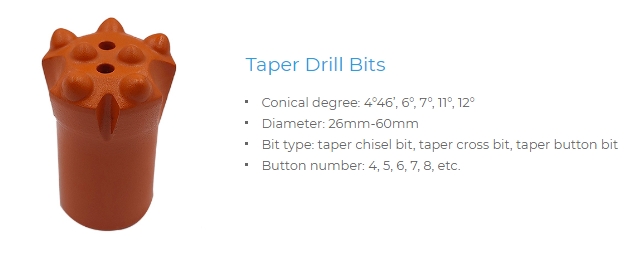

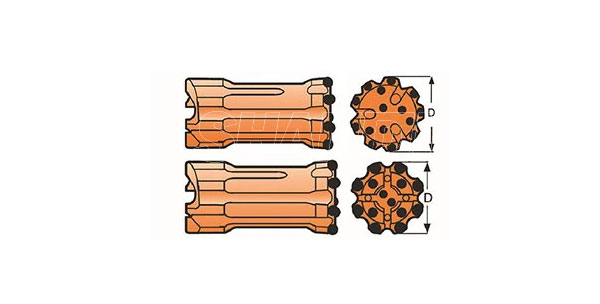

Taper bits 7 buttons 34mm Product Description:

Diameter: 34mm

Number of drill bit buttons: 7

Type: taper button bits

Usage: Rock drilling

Product Features:

Cone shaped design: This design helps to maintain stability and improve drilling efficiency during the drilling process.

7 drill bit buttons: This indicates that there are 7 main cutting points on the drill bit, which are responsible for breaking rocks during the drilling process.

34mm diameter: suitable for use in rock drilling projects that require larger apertures.

Use of drill bits:

Mainly used in the energy and mining industries, as well as drilling in quarries.

Suitable for hard rock drilling, such as granite, marble, etc.

Related parameters (refer to the information in the article):

Angle: 7/11/12 degrees (this may refer to the tilt angle or cutting angle of the drill button).

Material: Tungsten carbide, which is a common hard alloy used in the manufacturing of drill bits, has high hardness and wear resistance.

Supply capacity, packaging, and transportation methods may vary depending on the supplier.

Certification and Quality Assurance:

Some suppliers provide quality certifications such as ISO90001.

May provide mechanical testing reports and factory inspection services.

Other information:

Colors: may include black, yellow, orange, etc.

Application field: Not limited to rock drilling, it can also be used in other industrial applications that require drilling.

Applicable rock drill type: top hammer rock drill

Compatible sizes: 76mm, 89mm, 102mm

Thread standards: T51, R51, T60, ST68

T38 64mm button drill bit detailed specifications:

Shape: spherical

Button size: Front 4 x 10mm

Specification: 8 x 10mm

Flushing holes: 2 front and 2 side

Body type: Normal

Part number: P/N4148300708

T38 76mm ballistic button drill bit detailed specifications:

Button size: Front 4 x 11mm

Specification: 8 x 12mm

Flushing holes: 2 front and 2 side

Body type: Normal

Part number: P/N4148300729

The application scenarios of T38 64mm Thread Button Drill Bit are mainly concentrated in the energy and mining fields, which can be summarized as follows:

Rock mining and drilling:

Due to its high performance, large diameter (64mm), and T38 thread design, this drill bit is particularly suitable for drilling and mining operations in hard rocks.

It can maintain stable drilling efficiency under various rock conditions, such as coal mines, gold mines, iron mines, etc.

Mining Engineering:

In mining engineering, a large amount of drilling work is often required, such as blasting holes, ventilation holes, drainage holes, etc. The T38 64mm Thread Button Drill Bit can efficiently complete these tasks and improve the efficiency of mining engineering.

It is suitable for various mining environments, including open-pit and underground mines.

Water wells and geothermal drilling:

In water well drilling, this type of drill bit can penetrate various formations and quickly reach the target depth, thereby improving drilling efficiency.

For geothermal drilling projects, the T38 64mm Thread Button Drill Bit also performs well, meeting the requirements for drilling depth and accuracy in geothermal drilling.

Tunnels and underground engineering:

In tunnels and underground engineering, advanced geological drilling is often required to understand the geological conditions ahead. The T38 64mm Thread Button Drill Bit can provide accurate drilling data, providing strong support for engineering design and construction.

Engineering drilling and exploration:

The T38 64mm Thread Button Drill Bit is also widely used in geological exploration, resource exploration, and other fields. It can efficiently and accurately obtain samples and data of underground rock layers, providing strong support for exploration work.

In summary, the T38 64mm Thread Button Drill Bit has broad application prospects in the energy and mining fields due to its high performance, large diameter, and T38 thread design. Whether it is rock mining, mining engineering, water wells, geothermal drilling and other fields, it can provide efficient and stable drilling support for engineering.

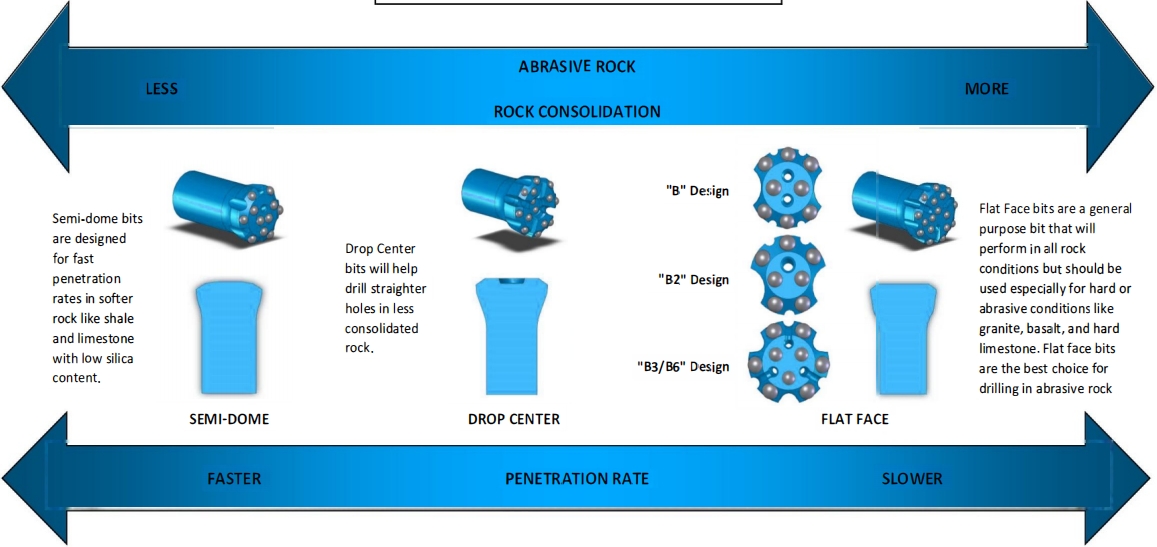

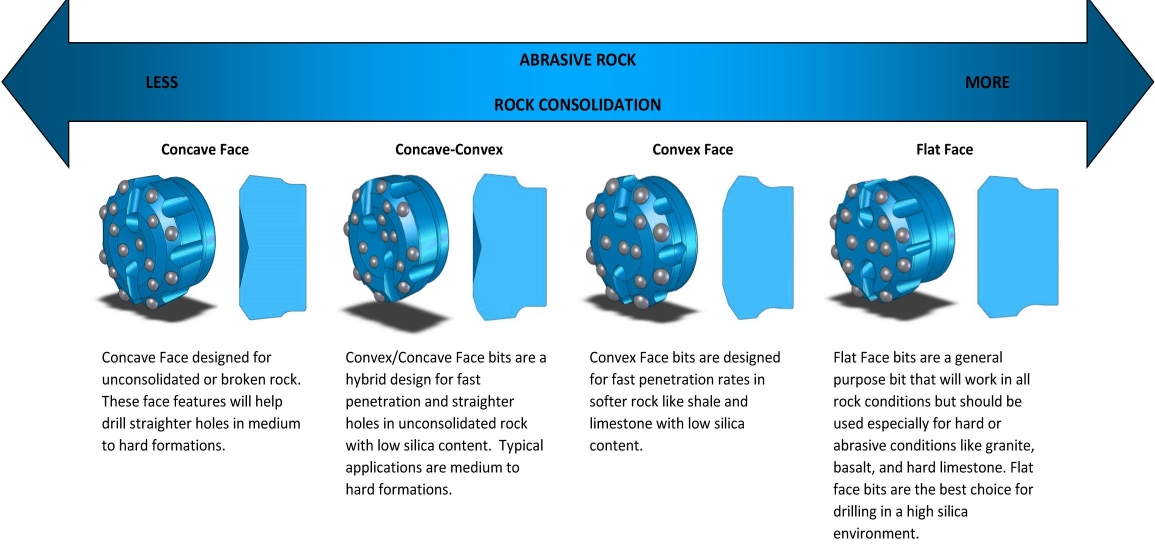

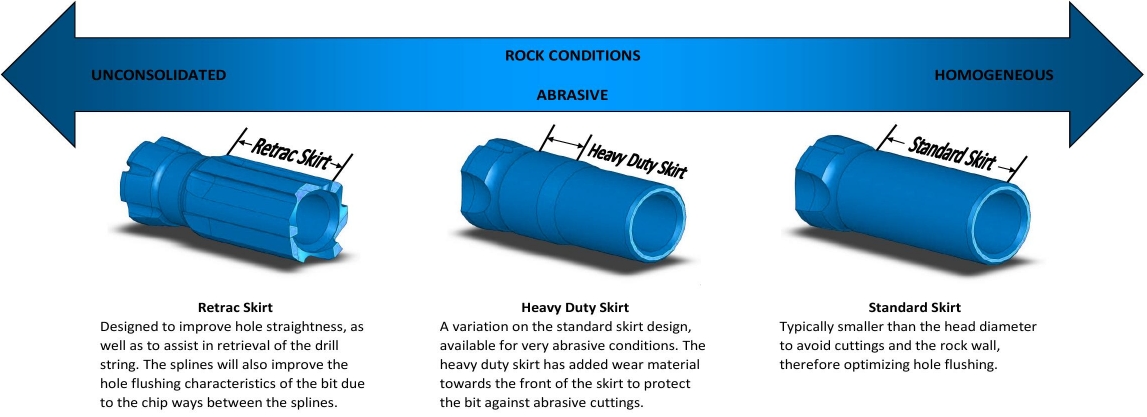

The selection of TOP-HAMMER BUTTON BITS usually involves the following considerations:

Drill diameter: The selection of an appropriate diameter depends on specific drilling requirements, including rock hardness, pore size requirements, and drilling efficiency.

Drill bit type: According to the type and hardness of the rock, different types of drill bits can be selected, such as tapered button bits and threaded button bits.

Drill material: The selection of drill material is crucial for its performance and service life.

Drill bit structure: The design of drill bit structure directly affects its drilling efficiency and durability.

Carbide Designs

Perhaps the most fundamental decision when selecting differentcarbide configurations is profile shape.Button bits most commonlyhave either a hemispherical or semi-ballistic carbide design;howeverit is not uncommon to use other carbide designs as well.Below areselections of the different carbide designs offered by RockmoreInternational.

Carbide Configurations

Most face designs for button bits are offered in multiple carbideconfigurations and typically differ in diameter,shape (i.e.profile)andquantity.There are somegeneral guidelines to follow while selectingbetween multiple carbide configurations including resistance to wear,penetration rate,vibration,and specific rock conditions.

BIT FACE SELECTION PDF DOWNLOAD: BIT FACE SELECTION

T51 Bits is a part of the T51 series of top hammering rock tools, mainly used for drilling operations. This series includes various drill bits and accessories with different diameters to meet the drilling needs of different depths and types of rocks.

Drill bit model and specifications:

The T51 series drill bits include various models, such as T51-89mm, T51-102mm, T51-115mm, T51-127mm, etc., with a wide range of diameters to meet different aperture requirements.

The drill bit adopts a spherical or parabolic button design, which helps to maintain stability and improve drilling efficiency during the drilling process.

Attachment type:

Dome bit for reaming: such as T51-152mm, it also has a spherical or parabolic button design.

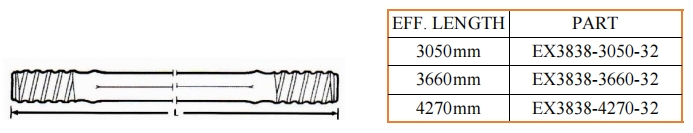

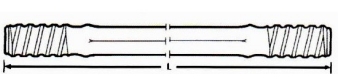

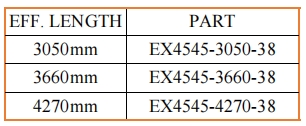

Extension rods: such as T51-Round52-T51, with lengths including 3050mm, 3660mm, 4270mm, 4880mm, 5530mm, 6095mm, and other specifications to meet drilling needs at different depths.

M/F rods: also available in various length specifications, making it easy to connect and expand during drilling.

Guide rods and guide tubes: These accessories help improve drilling accuracy and stability.

Technical features:

The T51 bits have a flushing hole design with a diameter of 21.50mm, which helps to remove rock debris during drilling, maintain the cleanliness of the drill bit, and improve drilling efficiency.

The wrench flat has a size of 45mm, making it convenient to use a wrench for replacing or adjusting drill bits.

Applicable scope:

T51 bits are suitable for various rock drilling operations, including but not limited to geological exploration, mineral resource development, basic engineering construction, and other fields.

How to purchase T51 bits

When choosing T51 Bits, you can refer to the following steps and key points to ensure that you choose the right product:

Determine requirements:

Firstly, clarify the rock type, pore size requirements, and drilling depth for drilling, which will directly affect the selection of T51 bits.

Select drill bit model and specifications:

Select suitable T51 Bit models and specifications according to your needs, such as T51-89mm, T51-102mm, T51-115mm, etc. Ensure that the selected drill bit diameter meets the expected aperture requirements.

Considering technical characteristics:

Pay attention to the flushing hole design of T51 bits, which helps to remove rock debris during the drilling process, maintain the cleanliness of the drill bit, and improve drilling efficiency.

The size of the wrench’s flat surface is also a factor that needs to be considered to ensure that the wrench can be easily used for operation when replacing or adjusting the drill bit.

Consider attachment types:

According to the drilling depth and requirements, select suitable accessories such as reaming drill bits, extension rods, male and female joint rods, etc. Ensure that these attachments are compatible with the selected T51 bits and meet drilling requirements.

Pay attention to materials and quality:

The material of T51 Bits has a significant impact on its performance and service life. Priority should be given to selecting drill bits made of high-strength alloy steel and special heat treatment processes to ensure their wear resistance and durability.

Consider selecting manufacturers and brands with relevant certifications (such as ISO 9001:2000) to ensure product quality and reliability.

Comparing prices and services:

During the purchasing process, compare the prices and performance of T51 bits from different brands and models, and choose products with higher cost-effectiveness.

Pay attention to the after-sales service and technical support provided by manufacturers or suppliers to ensure timely and effective assistance during use.

View user reviews and cases:

Before purchasing, check other users’ evaluations and feedback on the product to understand its performance in actual use.

If conditions permit, it is possible to understand the application cases of the product in similar engineering or projects in order to better evaluate its performance and applicability.

What are the types of T51 bits

T51 bits usually refer to drill bits suitable for T51 Top Hammer drilling equipment. These drill bits have multiple types to choose from based on different rock types, drilling requirements, and pore sizes. The following are some common types of T51 bits:

Cone Bits:

Conical drill bits are suitable for various rock types, especially in harder rocks. They have great drilling ability and can maintain good stability during the drilling process.

Button Bits:

Ball toothed drill bits are commonly used for medium hardness rocks, such as sandstone, shale, and some granite. They have good wear resistance and a long service life.

According to the shape and arrangement of the ball teeth, they can be further subdivided into spherical and parabolic ball tooth drills.

Dome bits for Reaming:

Expanding drill bits are usually used to further enlarge the aperture in already drilled holes. They usually have larger diameters and special structural designs to ensure the integrity and stability of the hole wall during the expansion process.

Pilot bits:

A directional drill bit is used to guide the drilling direction, especially when precise control of the drilling path is required. They usually have smaller diameters and special guiding structures.

Carbide bits:

Hard alloy drill bits are made of hard alloy materials, which have high hardness and wear resistance. They are usually used for drilling into hard rocks and highly abrasive formations.

Diamond bits:

Although diamond drill bits are not common in T51 systems, they may need to be used in certain special applications. Diamond drill bits have extremely high hardness and wear resistance, making them suitable for drilling in extremely hard and highly abrasive formations.

Other special drill bits:

According to specific application requirements, there may also be other specially designed T51 bits, such as drill bits with cutting teeth, drill bits with spiral grooves, etc.

When selecting T51 bits, factors such as rock type, drilling depth, pore size, drilling speed, and budget need to be considered. In addition, it is important to choose a manufacturer with a good reputation and reliable technical support to ensure the purchase of high-quality T51 bits and good after-sales service.

T51 Bits service life

The service life of T51 bits is influenced by various factors, including rock type, drilling depth, frequency of use, maintenance, etc. Therefore, it is not possible to provide an exact number to indicate its service life. But here are some considerations and general rules regarding the service life of T51 Bits:

Rock type:

The degree of wear of T51 bits varies when drilling into different types of rocks. When drilling into hard rock or highly abrasive formations, the drill bit wears out quickly and has a relatively short service life.

Drilling depth:

The deeper the drilling depth, the greater the pressure and wear that the drill bit bears, and its service life is relatively short.

Usage frequency:

High frequency use will accelerate the wear of T51 bits and shorten their service life.

Maintenance:

Regular maintenance and upkeep of T51 bits, such as cleaning and lubrication, can extend their service life.

Drill quality:

Choosing high-quality and wear-resistant T51 bits can extend its service life to a certain extent.

General pattern:

Under normal use and maintenance conditions, the service life of T51 Bits typically ranges from tens to hundreds of hours. But please note that this is only a rough range, and the specific service life may vary due to various factors.

If encountering abnormal situations during the drilling process, such as sudden increase in pressure, abnormal noise, etc., drilling should be stopped immediately and T51 bits should be checked to avoid further damage.

To extend the service life of T51 bits, it is recommended to take the following measures:

Select appropriate T51 bits based on rock type and drilling requirements.

Maintain appropriate drilling speed and pressure during the drilling process.

Regularly maintain and upkeep T51 bits to ensure they are in good working condition.

Pay attention to observing and checking the wear of T51 bits during use, and replace severely worn drill bits in a timely manner.

In summary, the service life of T51 Bits is a relatively complex issue that requires comprehensive consideration of multiple factors. By reasonable selection, correct use, and regular maintenance, its service life can be maximized.

TAPER DRILL STEEL is a special type of drill pipe material mainly used for small hole drilling operations in geological exploration, mining, construction and other fields. The following is a detailed introduction about TAPER DRILL STEEL:

Structure and Design:

TAPER DRILL STEEL typically adopts a conical design, which helps to better break rocks and soil during drilling and improve drilling efficiency.

The conical drill bit steel combines high-quality impact drill rods and wing designs similar to rotary drill bits, which help to discharge cutting materials from the hole while maintaining the straightness of the hole.

Working principle:

The working principle of TAPER DRILL STEEL is similar to traditional impact drill rods, which apply an impact force at one end to transmit the shock wave to the tungsten carbide rock drill bit at the other end, thereby breaking the rock.

At the same time, the drill bit/steel rod will rotate slightly to break new rock and blow air or air/water mixture into the hole through internal channels to remove cutting material from the surface of the drill bit and flush the cutting material out of the hole.

Features and advantages:

TAPER DRILL STEEL is suitable for harsh geological conditions, especially in situations where rock fragmentation is poor or there are cracks that absorb shock waves. Its design helps to reduce “sticking” and improve drilling success rates.

The conical design and wing structure help maintain the straightness of the holes, reduce deviations, and improve drilling quality.

Suitable for handheld small hole drilling, the length range is usually 0.4-8 meters, and can be customized according to specific needs.

Materials and Manufacturing:

TAPER DRILL STEEL is usually made of high-strength and wear-resistant materials such as stainless steel and high manganese steel to ensure a longer service life in harsh drilling environments.

During the manufacturing process, precision forging and heat treatment processes are used to ensure that the conical drill bit steel has excellent mechanical properties and wear resistance.

Application field:

TAPER DRILL STEEL is widely used in small hole drilling operations in geological exploration, mining, construction and other fields, such as soil sampling, rock drilling, foundation pile hole construction, etc.

Notes:

When using TAPER DRILL STEEL for drilling, appropriate drill bit models and lengths should be selected based on specific geological conditions and drilling needs.

Regularly inspect the wear of drill bits and replace severely worn ones in a timely manner to ensure drilling efficiency and safety.

Follow the correct drilling operation procedures and safety precautions to ensure the safe operation of drilling operations.

H-series models:

H19, H22, H25: These models usually indicate the diameter or size range of the drill bit. For example, H25 may indicate that this model is suitable for drill bits with a diameter of 25mm or similar sizes.

Features: High strength, high wear resistance, suitable for rock drilling and mining operations.

B-series models:

B19, B22, B25: Similar to the H series, The B series also represents the diameter or size range of drill bits.

Features: These models may focus more on specific geological conditions or drilling depths, providing different hardness and wear resistance.

7 degrees, 11 degrees, 12 degrees Model:

These numbers may indicate the taper or angle of the drill bit. Cone is the degree to which the diameter of a drill bit gradually changes from one end to the other.

Features: Different tapers are suitable for different rock types and drilling conditions. For example, a steeper taper may be more suitable for drilling in hard rock, while a gentler taper may be more suitable for drilling in soft rock or soil.

Length range:

The length range of TAPER DRILL STEEL is usually 0.8-8m, and the specific length can be customized according to drilling requirements.

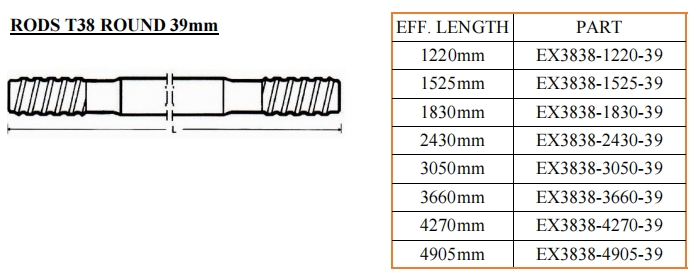

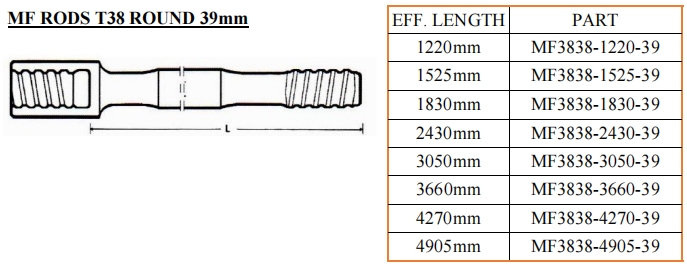

Hex Rods MF Rod, designed specifically for T38 rock tool drilling equipment, has a series of characteristics and specifications. The following is a detailed introduction to it:

Basic information

Model: Hex Rods MF Rod (compatible with T38 thread system)

Usage: Used for T38 rock tool drilling equipment, especially suitable for situations that require high-precision and high-efficiency drilling.

technical parameter

Material:

Mainly using high-strength alloy steel to ensure the strength and wear resistance of drill pipes.

High strength chromium molybdenum steel and other high-quality materials provide high fatigue strength and good wear resistance.

Processing method:

Using the most advanced CNC machinery for processing and heat treatment to ensure the accuracy and durability of the product.

Length:

According to different needs and application scenarios, the length is usually between 600mm and 6400mm and can be customized.

Diameter:

The diameter range may cover 20-50mm, depending on product specifications and application scenarios.

Thread system:

Adopting T38 thread system to ensure compatibility and efficiency with T38 rock tool drilling equipment.

Performance characteristics

High precision: As the first drill pipe in the drill string, it can further improve drilling accuracy.

High efficiency: Under good rock conditions, compared to the combination system of drill pipe and connecting casing, it can produce more straight holes and at least 10% higher penetration rate.

Durability: High strength materials and advanced processing technology ensure the durability and stability of drill pipes.

Application scenarios

Especially suitable for step and long hole drilling, as well as other situations that require high-precision and high-efficiency drilling.

matters needing attention

Before use, please ensure the compatibility and compatibility between the drill pipe and T38 rock tool drilling equipment.

During use, please follow relevant safety regulations and operating guidelines to ensure the safety of personnel and equipment.

The drill pipe design adopts the T38 thread system, which is particularly suitable as the first drill pipe in a regular drill string. This choice can significantly improve the accuracy of drilling. Moreover, due to its unique speed rod design, under ideal rock conditions, it can create more straight holes and increase penetration by at least 10% compared to traditional drill pipe and connecting casing combination systems. This feature makes it an ideal choice for step and long hole drilling.

The following are the main features of the drill pipe:

High quality raw materials: Ensure excellent basic performance of drill pipes.

High grade steel manufacturing: precision machining and heat treatment are carried out through the most advanced CNC machinery, ensuring the durability and accuracy of drill pipes.

High strength chromium molybdenum steel: This material not only has high fatigue strength, but also has excellent wear resistance, ensuring the stability and reliability of drill pipes under long-term and high-strength operations.

Model: T38

Application: Mainly used in coal mining, quarry drilling, construction, stone drilling and other fields.

Advantages: High performance, wear resistance, and factory price.

technical parameter

Material: Carbon steel, with high strength and wear resistance.

Thread: T38, may also include other thread specifications such as R25, R32, T45, T51, Gt60, etc.

Length: The length of products provided by different suppliers may vary, such as 3050mm, 3660mm, etc., or customized according to customer needs.

Packaging: Products can be packaged according to customer needs, such as wooden packaging.

price information

Price range: Prices may fluctuate depending on different suppliers and order quantities. For example, some suppliers offer prices ranging from US 216.00 to 246.00 per Set, while others offer prices ranging from US 70.00 to 300.00 per Piece.

Minimum order quantity: usually 1 Set or 10 Pieces, but it may vary depending on the supplier’s requirements.

Model and size:

Model: R28 Drifter Rod Hex28

Length: 2400mm

Materials and Applications:

This product may be used for drilling or drilling equipment in tunnel engineering, with sufficient strength and toughness to handle drilling in rocks or other hard materials.

The common material may be high-strength alloy steel, which can withstand high stress and wear resistance.

Connection and adaptation:

Due to its Hex28 model, it indicates that its hexagonal cross-section may be used in specific drilling rigs or drilling tool systems.

Usually, this hexagonal drill pipe is threaded to the corresponding drilling rig or tool head to ensure stability and connection reliability during the drilling process.

Performance characteristics:

High strength: able to withstand high stress and impact during drilling.

Wear resistance: able to resist the wear caused by long-term drilling.

Adaptability: May be suitable for various drilling conditions, including rocks and soils with different hardness.

Drill rod using R25/R28/R32 thread system. Suited for short hole drilling operations.Used in drifting and tunneling.

Competitive Advantage

High strength chromium-molybdenum steel with high fatigue strength and excellent wear resistance

Specification(R28 Drifter rod)

| Product | R28 Drifter Rod |

| Diameter | 28mm |

| Length | 2400mm |

| Weight | 12.2KG |

| Color | Black |