T51 high-speed rock drilling drill rod

Application field:

mining

quarry

Tunnel excavation

Building construction

Color: Black/Customized

Thread type: R32, R38, T38, T45, T51

Drill pipe size:

Circular 32mm

Circular 39mm

Circular 46mm

Circular 52mm

Process treatment: heat treatment and comprehensive carburization

Product features:

High strength: After heat treatment and comprehensive carburization, it ensures that the drill rod has excellent strength and durability in harsh rock drilling environments.

Multiple thread specifications: Provide multiple standard thread specifications to meet different drilling needs.

Customized services: Colors and sizes can be customized according to customer needs to meet specific project requirements.

Efficient drilling: designed specifically to improve drilling speed and suitable for various rock drilling operations.

Widely used:

Whether in mines, quarries, tunnel construction and construction projects, T51 high-speed rock drilling drill rods can perform excellently, helping you improve work efficiency and reduce maintenance costs.

Type:T51 Speed Rod T51-Round 52-T51 Flushing Hole 21.5 mm

| Product name | Speed Drill Rods |

| Application | Construction works , Energy & Mining, water well |

| Color | Customized |

| Material | Carbon steel |

| Advantage | High-efficiency |

| Quality | High Level |

Specification

| Part Number | Product Code and Brief | Length ( | Length | Diameter | Diameter | Weight |

| Description | mm) | (ft/inch) | (mm) | (inch) | (kg) | |

| 4148300954 | MF52-T51-1830, | 1830 | 6 | 52 | 2 | 30.6 |

| T51 Speed Rod, | ||||||

| T51-Round 52-T51, | ||||||

| Flushing Hole 21.5mm | ||||||

| 4148300955 | MF52-T51-3050, | 3050 | 10 | 52 | 2 | 48.3 |

| T51 Speed Rod, | ||||||

| T51-Round 52-T51, | ||||||

| Flushing Hole 21.5 mm | ||||||

| 4148300956 | MF52-T51-3660, | 3660 | 12 | 52 | 2 | 57.1 |

| T51 Speed Rod, | ||||||

| T51-Round 52-T51, | ||||||

| Flushing Hole 21.5 mm | ||||||

| 4148300957 | MF52-T51-4270, | 4270 | 14 | 52 | 2 | 66.0 |

| T51 Speed Rod, | ||||||

| T51-Round 52-T51, | ||||||

| Flushing Hole 21.5 mm | ||||||

| 4148300958 | MF52-T51-4880, | 4880 | 16 | 52 | 2 | 74 |

| T51 Speed Rod, | ||||||

| T51-Round 52-T51, | ||||||

| Flushing Hole 21.5 mm | ||||||

| 4148300959 | MF52-T51-5530, | 5530 | 18 1/7 | 52 | 2 | 84.2 |

| T51 Speed Rod, | ||||||

| T51-Round 52-T51, | ||||||

| Flushing Hole 21.5 mm | ||||||

| 4148300960 | MF52-T51-6095, | 6095 | 20 | 52 | 2 | 92.4 |

| T51 Speed Rod, | ||||||

| T51-Round 52-T51, | ||||||

| Flushing Hole 21.5 mm |

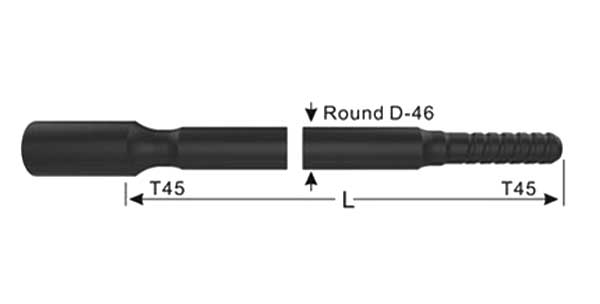

Product type: Drill Button Bits

Thread specification: T45

Diameter: 76mm

Main body type: Retrac Body

Tip shape: spherical or ballistic

Material: Tungsten Carbide, high-strength alloy steel (Tungsten Carbide), High Strength Alloy Steel)

Color: Green or Customized

Processing type: Forging

Application areas: mining operations, drift and tunnel excavation, quarries, mining operations, Drifting And Tunneling, Quarrying, Construction)

Formation type: Hard Formations

Connection method: T45 Drill Rod

Highlights:

Thread rock drilling tools

Tungsten carbide embedded rock drilling tool

T45 button drill bit for rock drilling

Product Name: T45 76mm Tungsten Carbide Insert Scalable Drill Bit

Our strengths:

Using high-quality raw materials for production to ensure product quality and performance.

We have rich manufacturing experience and strict quality control system to ensure that every product meets high standards.

Product Description

| Product Name | different rock hardness drilling button bit | ||

| Description | For different rock hardness mining,tunneling,quarrying button bit Button bit Made with high quality of best quality alloy steel bar and tungsten carbide, through heat treatment. | ||

| Material | Alloy steel bar and tungsten carbide bit | ||

| MOQ | trial order 5-10pcs | ||

| Body Type | Normal type and retract type | ||

| Thread | R25,R28,R32,R38,T38,T45,T51,ST58,ST68 | ||

| Diameter | 32mm-152mm | ||

| Button shape | Spherical and Ballistic | ||

| Face shape | Flat shape and Drop-center shape | ||

Specification as below:

| Product Name | Bit Diameter | Carbide Button | Angle | Flushing Hole | Weight (kg) | |||

| (mm) | (inch) | Front(No. x mm) | Gauge(No. x mm) | Front | Side | |||

| T45 Retrac Bit | 70 | 2 3/4 | 3×11, 1×9 | 6×11 | 35° | 3 | – | 2.5 |

| 70 | 2 3/4 | 4×10, 1×10 | 8×11 | 35° | 4 | – | 2.5 | |

| 76 | 3 | 4×11 | 8×11 | 40° | 2 | – | 3.2 | |

| 76 | 3 | 4×11 | 8×12 | 35° | 2 | 1 | 3.2 | |

| 76 | 3 | 3×11, 1×11 | 6×13 | 35° | 3 | 1 | 3.2 | |

| 76 | 3 | 4×11, 1×11 | 8×11 | 35° | 4 | – | 3.2 | |

| 76 | 3 | 4×11, 1×11 | 8×12 | 35° | 4 | – | 3.2 | |

| 89 | 3 1/2 | 4×13 | 8×13 | 40° | 2 | – | 5.4 | |

| 89 | 3 1/2 | 6×11 | 8×12 | 35° | 2 | – | 5.4 | |

| 89 | 3 1/2 | 3×11, 2×11 | 8×13 | 35° | 3 | 1 | 5.4 | |

| 89 | 3 1/2 | 4×11, 1×11 | 8×12 | 35° | 4 | – | 5.4 | |

| 89 | 3 1/2 | 4×13, 1×13 | 8×13 | 35° | 4 | – | 5.4 | |

R25 spherical drill bit: a rock drilling tool designed specifically for drift and tunnel excavation

Product features:

This drill bit is designed for soft to medium hardness rock formations and is a high-speed drill bit. It uses spherical tungsten carbide inserts and is known for its excellent resistance to tungsten carbide fracture.

The SHANGIKE drilling equipment allows drilling workers to replace drill bits without replacing drill pipes. If the goal is to reduce hole deviation in small aperture drilling, the driller usually chooses a conical cross-section drill bit. Different taper angles exhibit different characteristics in terms of the “knock out” index – smaller taper angles can effectively prevent drill bit rotation. This drill bit is particularly suitable for drift and tunnel excavation operations.

The main body of the drill bit is made of high-grade steel and processed through advanced CNC machine tools and heat treatment processes to ensure the high quality and durability of the product.

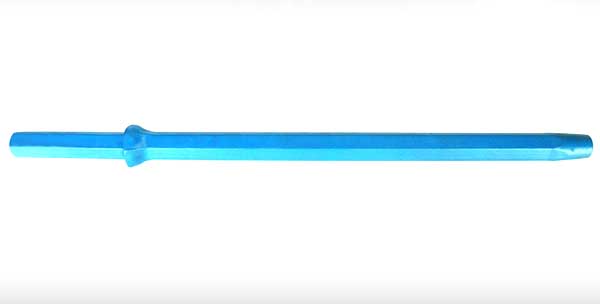

Tunneling Milling Extension Rod T38 CNC Rock Drilling Tools Product Description

Manufacturing process and materials:

The Tunneling Milling Extension Rod T38 CNC Rock Drilling Tools adopts CNC (Computer Numerical Control) machining technology to ensure product accuracy and consistency.

The raw material is high-quality steel, which has undergone advanced heat treatment technology to enhance the durability and reliability of the product.

Product features:

As a part of the drill pipe string, especially when used as the first drill pipe, it can significantly improve the accuracy of drilling.

Provide a variety of different lengths and thread sizes to choose from, such as R25 R28, R32, R38, T38, T45, T51, etc. to meet the needs of different tunnel excavation and rock drilling projects.

Application field:

Mainly used in the fields of tunnel excavation and rock drilling, including but not limited to mining operations, quarries, and basic engineering in various construction projects.

Price and Supply:

The price varies depending on the purchase quantity, specifically: 5-9 pieces are US150.00, 10-29 pieces are US145.00, 30-49 pieces are US140.00, 50-99 pieces are US120.00, and more than 100 pieces are more favorable prices.

Suppliers can provide a full range of drift, tunnel excavation drill rods and other drilling tools to meet the needs of different projects.

Other information:

The drill pipe adopts a threaded system, which improves the connection stability and work efficiency with the drilling rig.

Suppliers usually provide 3 months of after-sales service and warranty to ensure that customers receive timely technical support and solutions during use.

Summary: Tunneling Milling Extension Rod T38 CNC Rock Drilling Tools is a high-quality rock drilling tool manufactured using CNC machining technology. It has the characteristics of high precision, durability, and strong reliability, and is suitable for various tunnel excavation and rock drilling projects.

Specification

| Part Number | Product Code and Brief Description | Length (mm) | Length (ft/inch) | Diameter (mm) | Diameter (inch) | Weight (kg) |

| 4148300770 | ER39-T38-1220, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 1220 | 4 | 39 | 1 1/2 | 10.2 |

| 4148300771 | ER39-T38-1525, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 1525 | 5 | 39 | 1 1/2 | 12.8 |

| 4148300772 | ER39-T38-1830, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 1830 | 6 | 39 | 1 1/2 | 15.3 |

| 4148300773 | ER39-T38-2435, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 2435 | 8 | 39 | 1 1/2 | 20.4 |

| 4148300774 | ER39-T38-3050, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 3050 | 10 | 39 | 1 1/2 | 25.5 |

| 4148300775 | ER39-T38-3660, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 3660 | 12 | 39 | 1 1/2 | 30.9 |

| 4148300776 | ER39-T38-3965, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 3965 | 13 | 39 | 1 1/2 | 33.2 |

| 4148300777 | ER39-T38-4270, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 4270 | 14 | 39 | 1 1/2 | 35.7 |

| 4148300778 | ER39-T38-4880, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 4880 | 16 | 39 | 1 1/2 | 41.0 |

| 4148300779 | ER39-T38-5530, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 5530 | 18 1/7 | 39 | 1 1/2 | 46.3 |

| 4148300780 | ER39-T38-6095, T38 Extension Rod, T38-Round 39-T38, Flushing Hole 14.5 mm, Wrench Flat 32 mm | 6095 | 20 | 39 | 1 1/2 | 50.9 |

T51-Round 52-T51 threaded rock drill pipe, with its unique design and manufacturing process, has become a powerful assistant in drilling operations. All drill pipes are made of high-quality steel as raw materials, which have undergone CNC precision machining and advanced heat treatment technology to ensure their excellent durability and reliability. We provide a complete range of drift, tunnel excavation drill rods, and other drilling tools to meet different operational requirements.

This drill pipe is particularly suitable as the first normal drill pipe string, which can effectively improve the accuracy and efficiency of drilling. In addition, we also offer a variety of drill rods with different lengths and thread sizes for you to choose from, including R25 R28, R32, R38, T38, T45, T51, etc., to meet the needs of various complex work environments.

Application field:

Mining operations: In mining operations, this drill pipe can effectively improve drilling efficiency and assist in the mining and extraction of ore.

Quarry: In the quarry, drill pipes can easily handle rocks of various hardness, providing strong support for stone mining.

Drift and Tunnel Excavation: During the excavation process of tunnels and underground engineering, this drill pipe can ensure the accuracy and stability of drilling, improve the quality and safety of the project.

Construction and other fields: In addition, this drill pipe is widely used in construction, transportation, and other fields that require drilling operations, providing reliable drilling solutions for various projects.

Specification:

| Extension Rod T51-Round 52-T51 Flushing Hole 21.5 mm Wrench Flat 45 mm | Lengthmm | Lengthft | Diametermm | Diameterinch | Weightkg | Part Number | Product Code |

| 3050 | 10 | 52 | 2 | 45.3 | 4148300947 | ER52-T51-3050 | |

| 3660 | 12 | 52 | 2 | 54.1 | 4148300948 | ER52-T51-3660 | |

| 4270 | 14 | 52 | 2 | 63 | 4148300949 | ER52-T51-4270 | |

| 4880 | 16 | 52 | 2 | 71.8 | 4148300950 | ER52-T51-4880 | |

| 5530 | 18 1/7 | 52 | 2 | 81.2 | 4148300951 | ER52-T51-5530 | |

| 6095 | 20 | 52 | 2 | 89.4 | 4148300952 | ER52-T51-6095 |

| MF-Rod T51-Round 52-T51 Flushing Hole 21.5mm | Length mm | Length ft | Diameter mm | Diameterinch | Weight kg | Part Number | Product Code | ||||||||||||||||||||||||||||||||||||||

| 1525 | 6 | 52 | 2 | 26.2 | 4148300953 | MF52-T51- 1525 | |||||||||||||||||||||||||||||||||||||||

| 1830 | 8 | 52 | 2 | 30.6 | 4148300954 | MF52-T51- 1830 | |||||||||||||||||||||||||||||||||||||||

| 3050 | 10 | 52 | 2 | 48.3 | 4148300955 | MF52-T51-3050 | |||||||||||||||||||||||||||||||||||||||

| 3660 | 12 | 52 | 2 | 57.1 | 4148300956 | MF52-T51-3660 | |||||||||||||||||||||||||||||||||||||||

| 4270 | 14 | 52 | 2 | 66 | 4148300957 | MF52-T51-4270 | |||||||||||||||||||||||||||||||||||||||

| 4880 | 16 | 52 | 2 | 74 | 4148300958 | MF52-T51-4880 | |||||||||||||||||||||||||||||||||||||||

| 5530 | 18 1/7 | 52 | 2 | 84.2 | 4148300959 | MF52-T51-5530 | |||||||||||||||||||||||||||||||||||||||

| 6095 | 20 | 52 | 2 | 92.4 | 4148300960 | MF52-T51-6095 | |||||||||||||||||||||||||||||||||||||||

| Extension Rod T45-Round 46-T45 Flushing Hole 17 mm Wrench Flat 38 mm | Length mm | Length ft | Diameter mm | Diameterinch | Weight kg | Part Number | Product Code | ||||||||||||||||||||||||||||||||||||||

| 1830 | 6 | 46 | 1 4/5 | 21.6 | 4148300867 | ER46-T45-1830 | |||||||||||||||||||||||||||||||||||||||

| 2435 | 8 | 46 | 1 4/5 | 28.3 | 4148300868 | ER46-T45-2435 | |||||||||||||||||||||||||||||||||||||||

| 3050 | 10 | 46 | 1 4/5 | 35.2 | 4148300869 | ER46-T45-3050 | |||||||||||||||||||||||||||||||||||||||

| 3660 | 12 | 46 | 1 4/5 | 42.1 | 4148300870 | ER46-T45-3660 | |||||||||||||||||||||||||||||||||||||||

| 4270 | 14 | 46 | 1 4/5 | 48.9 | 4148300871 | ER46-T45-4270 | |||||||||||||||||||||||||||||||||||||||

| 5530 | 18 1/7 | 46 | 1 4/5 | 63 | 4148300872 | ER46-T45-5530 | |||||||||||||||||||||||||||||||||||||||

| 6095 | 20 | 46 | 1 4/5 | 69.3 | 4148300873 | ER46-T45-6095 | |||||||||||||||||||||||||||||||||||||||

| MF-Rod T45-Round 46-T45 Flushing Hole 17 mm | Length mm | Length ft | Diameter mm | Diameterinch | Weight kg | Part Number | Product Code |

| 1525 | 5 | 46 | 1 4/5 | 21.2 | 4148300874 | MF46-T45-1525 | |

| 1830 | 6 | 46 | 1 4/5 | 24.6 | 4148300874 | MF46-T45-3050 | |

| 3050 | 10 | 46 | 1 4/5 | 38.2 | 4148300874 | MF46-T45-1830 | |

| 3660 | 12 | 46 | 1 4/5 | 45 | 4148300874 | MF46-T45-3660 | |

| 4270 | 14 | 46 | 1 4/5 | 51.9 | 4148300874 | MF46-T45-4270 | |

| 5530 | 18 1/7 | 46 | 1 4/5 | 66 | 4148300874 | MF46-T45-5530 | |

| 6095 | 20 | 46 | 1 4/5 | 72.3 | 4148300874 | MF46-T45-6095 |

Description of the 4 Inch / 6 Inch T38 Hex Extension Rod Threaded Drill Rod

Our T38 Hex Extension Rod Threaded Drill Rods, available in 4 inch and 6 inch lengths, are designed to enhance drilling precision. When used as the initial rod in a standard drill string, they contribute significantly to improved drilling accuracy. Additionally, owing to their speed rod design, they produce straighter holes and achieve at least a 10% higher penetration rate in favorable rock conditions compared to traditional rod and coupling sleeve systems.

The material chosen for these drill rods is subjected to rigorous heat treatment to unleash its full potential, ensuring that only the finest material and heat treatment processes are utilized.

Technical Specifications

Thread System: T38

Color: Customizable based on customer requirements

Material: Tungsten carbide and high-strength alloy steel

Processing: CNC milling and proprietary heat treatment process

Type: T38 Hex Extension Rod with T38-Hex 32-T38 Flushing Hole of 9.6 mm

Applications

Underground Mining

Tunneling

Competitive Advantage

These drill rods are crafted from high-strength chromium-molybdenum steel, which boasts exceptional fatigue strength and wear resistance, making them a superior choice for demanding applications.

Taper Drill Rod H25×108 (55SiMnMo): The Ultimate Tool for Precision Drilling

In the demanding world of precision drilling, having the right tools is crucial. That’s why we’re proud to introduce our Taper Drill Rod H25×108, crafted from premium 55SiMnMo steel. This specialized rod is designed to handle the toughest drilling challenges with ease and precision.

The Power of 55SiMnMo Steel

55SiMnMo is a highly specialized alloy steel, known for its excellent wear resistance, strength, and ductility. When crafted into a taper drill rod, it offers unmatched performance and durability. The H25×108 size is perfect for a wide range of drilling applications, from mining to construction and beyond.

Precision Taper Design

The taper design of our drill rod allows for smooth and efficient penetration into even the hardest rock formations. The gradual reduction in diameter from the shank to the tip reduces stress concentrations, minimizing the risk of breakage or failure during drilling operations. This ensures that you can drill with confidence, knowing that your tool is built to last.

Unmatched Durability

With 55SiMnMo steel as its backbone, our Taper Drill Rod H25×108 is built to withstand the rigors of continuous use in harsh environments. The high-grade material ensures excellent wear resistance, so you can enjoy a longer service life and fewer replacements.

Versatility for Any Application

Whether you’re drilling into granite, marble, or any other hard material, our Taper Drill Rod H25×108 is ready for the job. Its precision taper design and superior material composition make it a versatile tool that can be adapted to a wide range of drilling applications.

Why Choose Our Taper Drill Rod?

Premium Material: Crafted from 55SiMnMo steel, our taper drill rod offers unmatched strength, durability, and wear resistance.

Precision Design: The taper design ensures smooth penetration and reduced stress concentrations, minimizing the risk of breakage or failure.

Versatility: Our taper drill rod is suitable for a wide range of drilling applications, making it a valuable addition to your toolbox.

Reliable Supplier: We have a reputation for providing high-quality products and excellent customer service. You can trust us to deliver the best taper drill rod for your needs.

In conclusion, our Taper Drill Rod H25×108 (55SiMnMo) is the ultimate tool for precision drilling. With its superior material composition, precision taper design, and unmatched durability, it’s the perfect choice for handling the toughest drilling challenges. Contact us today to learn more about how our taper drill rod can transform your drilling operations.

Tapered Drill Rods: The Ultimate Choice for South African Mining and Drilling Operations

In the vast and diverse mining landscape of South Africa, the demand for high-quality, reliable drilling equipment is unwavering. Among the many crucial components, the tapered drill rod stands out as a crucial tool that ensures efficient and cost-effective drilling operations.

Why Choose Tapered Drill Rods?

Tapered drill rods are designed with a gradual reduction in diameter from the shank to the tip. This unique design offers several advantages that make them a preferred choice for South African mining and drilling professionals:

Enhanced Penetration: The tapered shape allows the drill rod to easily penetrate hard and abrasive rock formations. This significantly improves the drilling speed and efficiency.

Reduced Breakage: The gradual tapering reduces stress concentrations at the point of impact, thereby minimizing the risk of breakage or failure during drilling operations.

Improved Durability: High-grade steel and advanced heat treatment processes ensure that tapered drill rods are extremely durable and can withstand the rigors of continuous use in harsh mining environments.

Versatility: Available in various lengths and taper degrees, tapered drill rods can be customized to meet the specific needs of different drilling applications.

South Africa’s Leading Supplier of Tapered Drill Rods

At [Company Name], we are proud to be the leading supplier of tapered drill rods in South Africa. Our products are manufactured using the latest technology and strict quality control measures to ensure their reliability and performance.

We offer a wide range of tapered drill rods in various sizes, including shank hexagons of 19108 mm, 22108 mm, 25108 mm, and 25159 mm. Our inventory also includes drill rods with taper degrees ranging from 6° to 12°, ensuring that you find the perfect fit for your drilling requirements.

Why Choose Us?

Quality Assurance: We adhere to strict international quality standards and employ advanced manufacturing techniques to ensure the highest quality of our tapered drill rods.

Extensive Inventory: Our extensive inventory ensures that we have the right tapered drill rod for your specific needs, always available in stock for prompt delivery.

Custom Solutions: We understand that every drilling operation is unique. Our team of experts can provide customized solutions to meet your specific requirements.

Competitive Pricing: We offer competitive pricing without compromising on quality. We believe in providing value for money and building long-term relationships with our customers.

In conclusion, tapered drill rods are a crucial component for successful drilling operations in South Africa. With our high-quality products, extensive inventory, and custom solutions, [Company Name] is your trusted partner for all your tapered drill rod needs. Contact us today to learn more about our products and services.

Carburization is a process that aims to enhance the durability and longevity of tapered drill rods by hardening their entire surface, both internally and externally. This hardening process strengthens the drill rods, making them more resilient for drilling tasks.

The shank hexagon of these drill rods comes in various sizes, including 19108 mm, 22108 mm, 25108 mm, and 25159 mm. Additionally, most lengths offer a choice of taper degrees, such as 6°, 7°, 11°, and 12°, which are often imported to ensure optimal drilling productivity.

Integral Drill Steel is a professional term in mechanical engineering, specifically referring to a type of drilling tool that integrates a drill tail, drill rod, and drill head. The following is a detailed

introduction to the overall steel brazing:

Definition and structure: Integrated steel brazing is an integrated tool consisting of three parts: the brazing tail, the brazing rod, and the brazing head, which are closely integrated during the manufacturing process to form a complete tool. This design enables the overall steel brazing to have higher strength and stability during use.

Usage: The integral steel drill bit is mainly used in conjunction with rock drills to drill rock holes, and is widely used in mining, hydropower construction, tunnel excavation, mining, rock drilling, as well as engineering fields such as mines, roads, and tunnels. In these projects, the overall steel drill can efficiently complete drilling tasks and improve engineering efficiency.

Advantages: The overall steel drill has advantages such as good transmission performance, improved drilling speed and efficiency. Due to its integrated design, the overall steel brazing is more stable during use, reducing failures caused by loose or detached components. In addition, the material of the overall steel brazing is usually high-strength steel, which has high wear resistance and corrosion resistance, and can adapt to various complex working environments.

Models and specifications: There are various models and specifications of overall steel brazing, such as B22 and B19 models. There are also multiple options for the types of drill bits, including straight and cross shapes. The length of the drill rod can be adjusted according to specific needs, ranging from 0.5m to 9m. There are also various sizes available for drilling, usually between 23mm and 43mm.

Usage and supporting equipment: The integral steel drill is usually used in conjunction with pneumatic rock drills, which drive the integral steel drill for drilling operations through the impact and rotation forces of the rock drill. Integrated steel drills are mainly used in fields such as quarrying and shallow hole rock drilling, and can meet the requirements of different engineering projects for drilling depth and accuracy.

SHANDIKE offers leading strength and penetration rates, ensuring excellent straightness and hole cleanliness for maximum drilling performance, ultimately saving on fuel costs. Additionally, SHANDIKE can customize its products according to customers’ specific length requirements, either based on samples or drawings. Our taper rod, crafted from high-quality steel and heat-treated, is suitable for hard rock drilling, effectively transmitting impact energy into the rock with minimal energy loss. Furthermore, button bits, compared to tapered chisel bits and tapered cross bits, boast superior technology, a significantly longer primary drilling time, and higher drilling efficiency.

Extension Rod Rock drifting and extension drill rods are for in drifting, tunneling, long-hole drilling, bench and production drilling industries. These rods are produced with round or hexagonal sections in all common thread designs, and in Male/Male (M/M) or Male/Female (M/F) connections.

Design features

High strength: These extension rods are designed to withstand high stress and impact forces during the drilling process, ensuring the continuity and safety of drilling operations.

Wear resistance: The surface is specially treated to improve wear resistance and extend its service life.

Corrosion resistance: Using corrosion-resistant materials or surface coatings to ensure stable performance even in humid or corrosive environments.

Easy to connect: Use standard threaded connections or other quick connection methods to ensure compatibility with other drilling equipment and convenience of connection.

Material properties

High quality alloy steel: MF R32 extension rods are usually made of high-strength alloy steel to ensure their strength and durability.

Heat treatment: After heat treatment to enhance its mechanical properties, such as tensile strength and yield strength.

Usage scenarios

Geological exploration: used for drilling rock layers in the exploration process of oil, natural gas, and mineral resources.

Basic engineering: used for drilling and reinforcing rock layers in the foundation treatment of bridges, high-rise buildings, and other buildings.

Other drilling applications: such as well drilling, tunnel engineering, underground pipeline laying, etc.

technical specifications

Length: The specific length may vary depending on the manufacturer and product model, but is usually suitable for scenarios that require extended drilling depth.

Diameter: Depending on the model and purpose, the diameter may also vary.

Connection method: Use standard threaded connection or other quick connection methods.

Maintenance and upkeep

Cleaning: After use, the soil and impurities on the surface of the extension rod should be cleaned in a timely manner to prevent corrosion and wear.

Lubrication: Apply an appropriate amount of lubricant to the threaded connection to reduce wear and friction.

Inspection: Regularly check the wear and damage of the extension rod, and replace or repair it in a timely manner if necessary.

Storage: Store in a dry, ventilated, and dust-free environment, avoiding prolonged exposure to damp or corrosive environments.

Please note that the above technical information is a simplified overview, and the specific technical specifications and performance parameters of the Rock Drill Extension Rod MF R32 may vary depending on the manufacturer and product model. Before purchasing, please be sure to check the technical specifications and instructions provided by the manufacturer.

The technical information of T45 12inch Underground Drill Rod usually includes information on its design characteristics, material properties, usage scenarios, size specifications, connection methods, and maintenance. Here is a simplified overview of technical materials:

Design features

High strength: T45 drill rods are designed to withstand high torque and tensile and compressive stresses, ensuring stability and durability during the drilling process.

Wear resistance: The surface of the drill pipe has been specially treated to improve wear resistance and extend its service life.

Corrosion resistance: using corrosion-resistant materials or surface coatings to adapt to various complex geological environments.

Material properties

High quality alloy steel: T45 drill rods are usually made of high-strength alloy steel to ensure their strength and durability.

Heat treatment: Drill pipes may undergo heat treatment to enhance their mechanical properties, such as tensile strength and yield strength.

Usage scenarios

Geological exploration: used for various geological exploration projects, such as drilling for oil, natural gas, and mineral resources.

Basic engineering: Used in foundation treatment of buildings such as bridges and high-rise buildings.

Water well drilling: applied in projects such as civil water wells and agricultural irrigation wells.

Size specifications

Length: 12 inches (304.8 millimeters)

Diameter: The specific diameter may vary depending on the application requirements, but T45 usually refers to a certain specification or type of drill pipe.

Thread specifications: The drill pipe is usually equipped with standard thread connections at both ends to ensure compatibility with other drilling equipment.

Connection method

Thread connection: The drill rods are tightly connected through threads to ensure stability and continuity during the drilling process.

Quick connection system: Some T45 drill pipes may be equipped with a quick connection system to improve connection efficiency and safety.

Maintenance and upkeep

Cleaning: After use, the surface of the drill pipe should be promptly cleaned of soil and impurities to avoid corrosion.

Lubrication: Apply an appropriate amount of lubricant to the threaded connection to reduce wear and friction.

Inspection: Regularly inspect the wear and damage of drill pipes, and replace or repair them in a timely manner if necessary.

Storage: Store in a dry, ventilated, and dust-free environment, avoiding prolonged exposure to damp or corrosive environments.

When choosing T45 Drill Steel, you should consider the following key factors to ensure that you purchase high-quality products that meet your needs:

Quality and Standards:

Confirm whether the product meets industry standards or specific quality requirements.

Check the reputation and quality assurance system of the manufacturer.

Dimensions and specifications:

Determine the required drill pipe length, diameter, and thread specifications based on your drilling needs.

Ensure that the selected T45 Drill Steel is compatible with your drill bit and other devices.

Material:

Understand the material of T45 Drill Steel to ensure it has sufficient strength and durability to handle drilling work.

High quality materials usually mean higher tensile strength, better wear resistance, and longer service life.

Surface treatment:

Check the surface treatment of the drill pipe, such as coating or heat treatment. These treatments can improve the corrosion resistance and wear resistance of drill pipes.

Connection method:

Understand the connection method of drill pipes to ensure that you can easily connect them and form a continuous drilling system.

Check the strength and reliability of the connecting parts.

Price and cost-effectiveness:

Compare the prices of different suppliers and products to find the most cost-effective option.

Be careful not to only pursue low prices and overlook quality and other important factors.

Supplier Reputation and Service:

Choose reputable suppliers who can usually provide more reliable products and better after-sales service.

Ask the supplier if they provide technical support, repair, and replacement services.

Security certification:

Check if the product has obtained relevant safety certification and compliance certificates to ensure compliance with safety standards.

Sample testing:

If possible, request the supplier to provide samples for testing to verify whether the quality and performance of the product meet your requirements.

Delivery time and after-sales service:

Confirm if the delivery time meets your project requirements.

Understand the supplier’s after-sales service policy, including returns, exchanges, repairs, and maintenance.

When purchasing T45 Drill Steel, it is best to compare with multiple suppliers in order to find the product that best suits your needs and budget. Meanwhile, please ensure sufficient communication with the supplier to ensure that you receive all the necessary information and support.

“T45 Extension Drill Rod” usually refers to a type of drill pipe designed to extend or increase the effective working length of the drill bit. In geological exploration, mining, oil drilling, or similar industries, when drilling to deeper depths, this type of drill rod is used to extend the length of the drill bit.

“T45” may be a specific specification or model code used to identify the size, material, strength, or other characteristics of this drill pipe. However, it should be noted that “T45” is not a universally recognized international standard code, it may be a custom code for a specific manufacturer or industry.

Extended drill rods typically have the following characteristics:

Length: The length of the drill pipe can be customized according to needs to adapt to different drilling depths.

Connectivity: The two ends of the drill pipe are designed with specific connection interfaces so that they can be connected to the drill bit and other drill pipes, forming a long and continuous drilling system.

Material: Drill pipes are usually made of high-strength, corrosion-resistant materials, such as steel or alloy steel, to ensure that they can withstand the pressure and wear during the drilling process.

Surface treatment: In order to increase the durability of drill pipes and reduce friction with rocks or other drilling materials, special treatments may be applied to the surface of drill pipes, such as coating with wear-resistant coatings or heat treatment.

Interchangeability: Drill pipes are usually interchangeable, which means that if a drill pipe is damaged or worn during the drilling process, it can be easily removed from the system and replaced with a new drill pipe.

Drill steel with T38 rope thread and a length of 1-1/2 inches refers to a type of steel rod specifically designed for use in rock drilling applications. The T38 rope thread refers to the threading pattern at one end of the drill steel, which is designed to attach the drill steel to a drilling machine or rig using a rope or cable.

Here are some key points about drill steel with T38 rope thread and 1-1/2-inch length: