Comparison of Cold Pressing vs. Hot Stamping Technologies for Rock Drill Bits

Cold Pressing Technology

Principle: Achieves dimensional accuracy and bonding through mechanical pressure (500-1,500 MPa) at room temperature, utilizing high-precision molds and hydraulic presses to press tungsten carbide (WC) or other wear-resistant materials into pre-machined slots of the drill bit matrix.

Advantages:

1. Low Equipment Cost

• Requires standard hydraulic presses and molds, reducing capital expenditure.

2. Complex Geometry Compatibility

• Enables precise manufacturing of spiral grooves, chip evacuation holes, and non-circular profiles.

3. High Production Efficiency

• Short cycle time (15-30 minutes per piece) suitable for batch production and customized orders.

4. Energy Conservation

• Eliminates thermal energy consumption and CO₂ emissions.

5. Matrix Material Versatility

• Suitable for low-carbon steel, ductile iron, and other heat-sensitive matrices to prevent thermal distortion.

Disadvantages:

1. Limited Bonding Strength

• Mechanical interlocking provides bond strength of 200-500 MPa, prone to failure under high-impact/vibrational conditions.

2. Reduced Wear Resistance

• Localized stress concentration leads to rapid edge wear in abrasive environments.

3. Dimensional Stability Issues

• Mold wear may cause tolerances exceeding ±0.05 mm for critical features.

Application Scenarios:

• Soft to medium-hard rock drilling (limestone, sandstone) in shallow holes (<300 m depth);

• Applications requiring frequent bit replacement (e.g., small-scale mining operations);

• Budget-constrained projects with moderate performance requirements.

Hot Stamping Technology

Principle: Utilizes high-temperature processing (>800°C) to soften the matrix material, enabling metallurgical bonding with WC inserts through diffusion bonding or vacuum brazing.

Advantages:

1. Superior Bonding Strength

• Metallurgical integration achieves bond strength exceeding 1,000 MPa, suitable for deep-hole drilling under extreme loads.

2. High-Temperature Stability

• Operates reliably at temperatures up to 1,200°C with minimal oxidation of WC components.

3. Long Service Life

• Reduced wear rate by 300-500% compared to cold-pressed bits in hard-rock formations.

4. Vibration Resistance

• Homogeneous microstructure minimizes fatigue cracks under cyclic loading.

Disadvantages:

1. Complex Process Control

• Requires precise temperature regulation (±5°C tolerance) and atmosphere control (argon/nitrogen shielding).

2. High Production Costs

• Energy consumption for heating (15-20 kWh per batch) and specialized equipment depreciation.

3. Thermal Distortion Risks

• Matrix material expansion coefficient mismatch may cause angular deviation (>0.1°) during cooling.

4. Material Limitations

• Not suitable for high-carbon steels or titanium alloys due to intergranular脆化 during heating.

Application Scenarios:

• Deep-hole exploration (oil/gas, geothermal drilling) with depths exceeding 1,000 m;

• High-hardness rock drilling (granite, basalt) in mining and tunneling;

• Precision drilling tools for rotary-percussive machines requiring <5% bit wear rate.

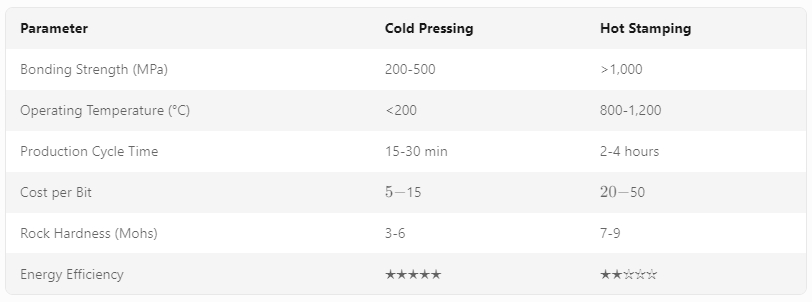

Technical Comparison & Selection Guide

Selection Recommendations:

• Choose cold pressing for shallow-hole operations in soft rocks with budget constraints.

• Opt for hot stamping in deep-hole, high-hardness formations requiring drill bit lifetimes >200 hours.

Future Development Trends

1. Hybrid Manufacturing: Combining hot-stamping with post-pressing heat treatment to enhance bond strength while reducing thermal distortion.

2. Advanced Materials: Adoption of titanium-based matrices (Ti-6Al-4V) for hot-stamping to improve corrosion resistance and fatigue life.

3. Automation Integration: AI-driven process optimization for real-time parameter adjustment in hydraulic presses and vacuum furnaces.

4. Nanostructured Coatings: Deposition of diamond-like carbon (DLC) or titanium nitride (TiN) films on WC inserts to reduce abrasive wear by 40-60%.