Drifter rod, R32–Hex 28–R25

About Drifter Rod R32 – Hex 28 – R25

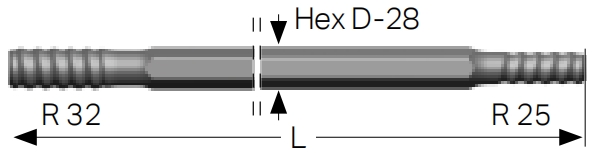

1. Product Specifications and Structure

The Drifter Rod R32 – Hex 28 – R25 features a unique specification: R32- Hex 28- R25. Here, R32 and R25 signify the thread specifications on both ends of the drill pipe, respectively. The notation Hex 28 indicates that the middle portion of the drill pipe adopts a hexagonal (Hex) structure, with a key dimension or characteristic related to the number 28, which could pertain to diameter, length, or another dimensional parameter as specified in the product description. Structurally, one end of the drill rod is equipped with an R32 thread, while the other end features an R25 thread, facilitating compatibility with various equipment and tools of differing specifications. The hexagonal mid-section enhances grip and handling, simplifying rotation and advancement during drilling operations.

2. Product Features

- High Strength: Constructed from high-strength alloy steel or equivalent materials, the rod can withstand significant torque and tension, ensuring stability and durability throughout the drilling process.

- High Precision: The threaded sections are precision-machined to guarantee a secure, stable connection with compatible equipment, minimizing the risk of loosening or detachment during drilling.

- Wide Applicability: Suitable for diverse drilling scenarios, including mining, tunnel excavation, and slope stability applications. The hexagonal design also facilitates easy connection and operation with manual or electric tools.

3. Application Scenarios

- Mining: In mining operations, the R32 – Hex 28 – R25 drift rod can be utilized for drilling ore cores or executing other mining-related tasks, thereby enhancing work efficiency.

- Tunnel Excavation: In tunnel engineering projects, this drift rod is employed to drill holes in tunnel walls for anchor support or other necessary operations, ensuring structural stability of the tunnel.

- Slope Treatment: During slope treatment, the R32 – Hex 28 – R25 drift rod can be used to drill drainage or grouting holes, thereby improving slope stability and mitigating the risk of geological hazards such as landslides.

4. Precautions for Use

- Inspection and Maintenance: Prior to use, the drift rod should be thoroughly inspected to ensure that its surface is free from cracks, wear, or other defects. Regular maintenance and upkeep are essential to prolong the service life of the rod.

- Correct Operation: When operating the drift rod for drilling purposes, adhere to relevant operating procedures and safety guidelines. Avoid applying excessive force or engaging in improper operations that may result in damage to the drill rod or personal injury.

- Adaptation Equipment: Choose equipment and tools that match the specifications of the drift rod for connection and operation. Ensure that connections are tight and stable to prevent loosening or detachment during the drilling process.