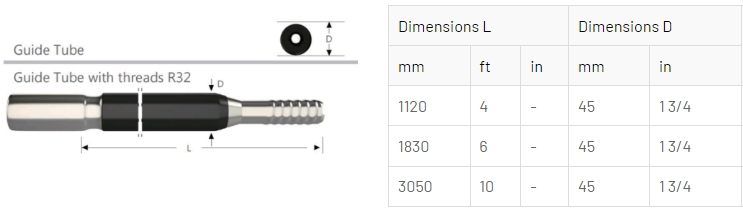

R32 (1 1/4″) Guide tube BENCH DRILLING

The use of guide tubes in underground deep hole drilling significantly contributes to achieving straighter holes. This not only enhances the drilling efficiency by minimizing deviations and waste, but also substantially reduces the overall operating costs associated with corrections and additional drilling.

When specifying guide tubes and drilling rods, a variety of thread types and sizes are available to cater to different drilling needs:

Thread Types: R32, T38, T45, T51, ST58, GT60, MT60, and ST68, each designed for specific applications and hole diameters.

Diameters (mm): 46, 56, 65, 76, and 87, offering a range of sizes to fit various drilling requirements and geological conditions.

Lengths (mm): 1220, 1525, 1830, 2280, 3050, and 3660, ensuring that the rods can reach the desired depths efficiently while maintaining structural integrity.

Highlights of the Drilling Rods:

Quality Materials and Heat Treatment: The thread ends of the rods are crafted from premium materials and undergo rigorous heat treatment processes. This not only hardens the material, reducing the likelihood of dents in the thread ends but also significantly extends the overall service life of the rods.

Reduced Breakage Risk: The heat treatment and use of high-quality materials also minimize the risk of thread end breakage. This ensures a smoother drilling operation with minimal interruptions and downtime.

Enhanced Durability and Efficiency: With less wear on the outer and inner sides of the rod ends, the rods maintain their threading integrity over extended periods. This reduces the need for frequent replacements and increases both use efficiency and service life.

Tight Tolerance for Safety and Durability: The rods are manufactured to precise tolerances, ensuring a snug fit and minimizing the potential for failures due to improper threading. This tight tolerance guarantees not only the safety of the drilling operation but also the durability and high quality of the final hole.

In summary, the combination of guide tubes and high-quality, precisely engineered drilling rods with a variety of thread types, diameters, and lengths ensures straighter holes, higher efficiency, cost savings, and long-term durability in underground deep hole drilling operations.