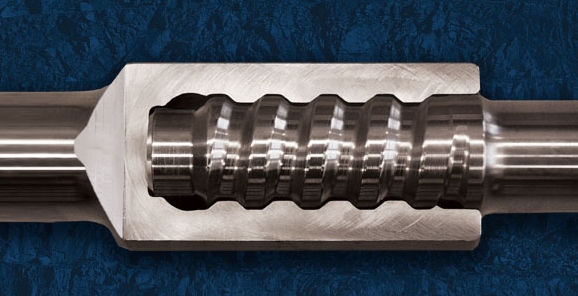

Rock Drill Extension Rod MF T51 T45 T38 R38 R32

Rock Drill Extension Rods: MF, T51, T45, T38, R38, and R32

Rock drill extension rods, also known as drill rods or drill pipes, are essential components in various mining, quarrying, and construction applications. They connect to the drill bit and transmit the rotational and impact forces generated by the rock drill to the rock formation. The different designations, such as MF, T51, T45, T38, R38, and R32, refer to the outer diameter (OD) of the rods in millimeters (mm). Here’s a brief overview of each type:

- MF: The MF designation typically stands for “metric fine” threads, which are used on some rock drill extension rods. The actual OD of an MF rod will depend on the specific manufacturer and application.

- T51: The T51 rod has an outer diameter of 51 mm. These rods are commonly used in applications that require a larger diameter for increased strength and rigidity.

- T45: The T45 rod has an outer diameter of 45 mm. It offers a good balance between strength, rigidity, and maneuverability, making it a popular choice for various drilling applications.

- T38: The T38 rod has an outer diameter of 38 mm. It’s widely used in mining, quarrying, and construction due to its versatility and ability to handle most drilling tasks.

- R38: The R38 designation typically refers to a rock drill extension rod with a 38 mm OD that uses a different thread standard or connection system compared to the standard T38 rod. The specific differences will depend on the manufacturer and application.

- R32: Similarly, the R32 rod has a 32 mm OD and uses a different thread standard or connection system. It’s important to ensure compatibility with your rock drill and other components when selecting an R32 rod.

When selecting a rock drill extension rod, it’s crucial to consider the specific requirements of your application. Factors such as the type of rock, drilling depth, hole diameter, and drilling method (e.g., rotary or percussive) will influence the choice of rod diameter, material, and thread standard. It’s also important to choose a reliable supplier or manufacturer that can provide quality rods that meet your specific needs.

Remember to check the compatibility of the rods with your rock drill and other components to ensure smooth and efficient drilling operations.