South Africa DTH Bits DHD360/COP64/QL60/SD6/MISSION60 Shank

DTH (Down The Hole) Bits, also known as down the hole drill bits, are important tools used for rock drilling and drilling. DHD360, COP64, QL60, SD6, and Mission60 are different models or specifications of down the hole drill bits, usually equipped with corresponding drill rods (Shank) for connecting the drilling rig and drill bit, transmitting torque and impact force.

Product Features

High wind pressure adaptability: These down the hole drill bits are typically designed to work in high wind pressure environments, capable of withstanding significant impact forces, ensuring drilling efficiency and quality.

Multiple specifications are available: DHD360, COP64, QL60, SD6, Mission60 and other models represent different drill bit specifications and sizes, suitable for drilling needs of different apertures and depths.

High quality material manufacturing:

1. High quality forging technology improves the fatigue strength of the drill bit body.

2. High quality hard alloy and suitable size can ensure the stability of the hard alloy life of the drill bit.

3. Easy to replace and maintain: The connection between the drill bit and drill rod is designed reasonably, making it easy to replace and maintain, reducing downtime and maintenance costs.

3、 Application Fields

These down the hole drill bits are widely used in mining, oil exploration, water well drilling, foundation engineering construction and other fields. They can efficiently penetrate rocks and soil, providing necessary drilling support for various engineering projects.

Three Kind Of Bit Face And Two Kind Of Button Shapes Are Available

Flat Face

Application: Hard and abrasive rock formation.

Typical formation: Granite, hard limestone, basalt.

Concave Face

Application: Medium hard to hard formations. Less abrasive, fractured formations. Excellent control for hole deviation.

Typical formation: Granite, hard limestone, basalt.

Convex Face

Application: Soft to medium hard rock. Non abrasive formation. High penetration rate.

Typical formation: Limestone, hard limestone, shale.

Features

1. Excellent insetting technology ensures that the carbides will not drop out from the bit body.

2. Advanced heat treatment equipment and technology to ensure the stability of the bit body performance.

3.Special bit surface design, structure design and specific processing technology are adopted to ensure the service life of DTH bit for different rock formation.

We can also supply other size bits with different shanks. If you need more information, please contact our sales for details.

3.5”: DHD3.5, IR3.5, BR33

4”: DHD340, COP44, QLX40, TD40, SD4, MISSION40

5”: DHD350, COP54, QL50, SD5, MISSION50

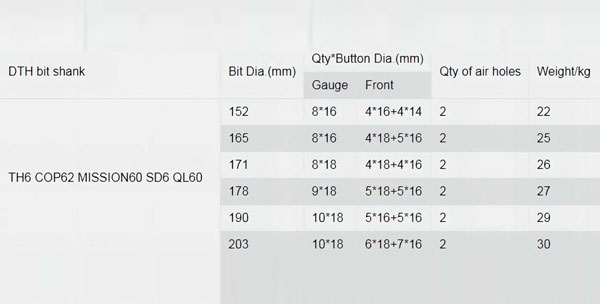

6’: DHD360, COP64, QL60, SD6, MISSION60

8”: DHD380, QL80, SD8, MISSION80

10”: SD10, NUMA100

Large Diameter DTH BITS

The large diameter bits are mainly used in three applications: embedded prefabrication pile, long spiral pile and large diameter end bearing pile.

We can supply large diameter bits with different size and shanks:

12”: DHD112, SD12, NUMA120, NUMA125

14”: NUMA125

18’: NUMA180

24”: NUMA240

Large Diameter DTH Bits Features

Wide applied for complex rock formation like caves, pebbles, fissures etc;

Drilling through hard rocks with high penetration rate;

Low air consumption.