The main reason for the failure of the drilling rod

Due to the development of China’s mining industry and the increasing scale of transportation infrastructure construction, as well as the government led requirements for mechanization, automation, and intelligent unmanned construction and mining, the drilling tool market has developed rapidly. It is said that there are dozens of manufacturers with a market size of billions of yuan. But there is still a lot of room for improvement in the performance of domestic brand products.

Today, let’s talk about our experience with the failure of drill rods on rock drilling rigs.

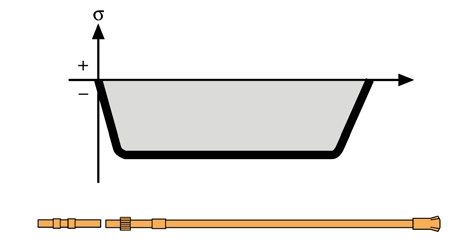

As the drill rod of the excavation trolley, it is the conductor that transfers the impact energy of the rock drill to the rock. Its working form is shown in the figure above. Regardless of the specifications, there are mainly several failure modes, namely normal wear. In addition, one is the breakage of the drill rod, and the other is the deformation of the connecting thread wear. Thread wear and deformation are common, while fractures are relatively rare, but the fracture points are almost always located about 50 centimeters away from the thread sleeve.

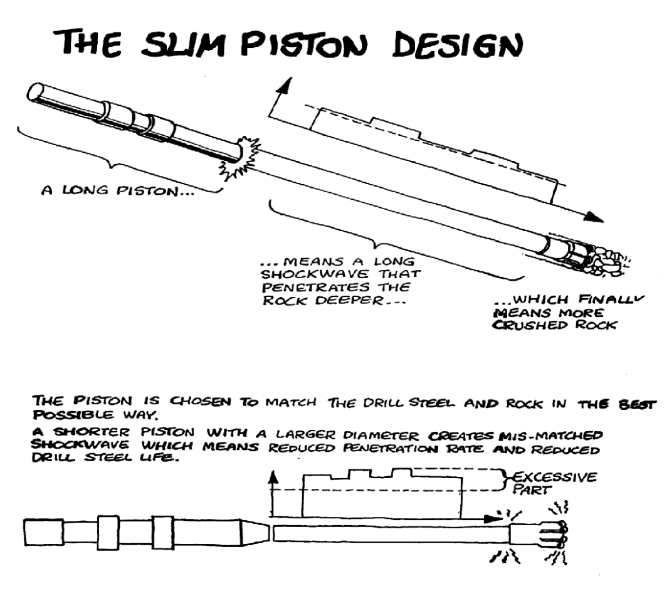

This situation is actually very consistent with the theory of energy transfer fluctuations in rock drills. When the impact piston strikes the drill tail, the kinetic energy of the impact piston is converted into stress waves, which are transmitted to the bottom of the hole through the drill rod and drill bit. In order to achieve optimal drilling economy, the entire system from the rock drill to the drilling tool to the rock must be coordinated with each other. According to the stress wave theory, stress waves are rectangular in shape, with the length of the rectangular wave being twice the length of the piston. The height of the rectangular wave depends on the velocity of the piston at the moment of impact, as well as the relationship between the cross-sectional area of the impact piston and the cross-sectional area of the drill rod, as shown in the figure. The energy generated by the impact of the rock drill piston is transmitted in the form of waves through the drill rod tail, and the drill rod breaks the rock. If you have hit a large hammer, held a drill rod, or chiseled a nail, you can feel the slight expansion of the drill rod with your palm or fingers, and have a sensory experience. According to this theory, at any given impact pressure, the stress wave amplitude in the drill pipe, i.e. the stress value, will become higher due to the reduction in the cross-section of the drill pipe. In order to achieve a longer service life for the drill tail and drill rod, it is important to ensure that the working pressure matches the cross-sectional size of the drilling tool at all times. Atlas Copco’s rock drills all adopt the concept of slender piston, and hope that the diameter of the drill bit tail and the drill rod match with it and are uniform without change, so that the peak value of the energy wave is uniform, which can not only achieve high transmission efficiency, but also improve the life of the drilling tool. This is also why Atlas rock drill is more efficient than other brands.

However, in reality, whether it is a drill tail or a drill rod, due to functional and processing requirements, its structural shape is difficult to fully meet the condition of no change in diameter. From the figure, we can see that in excavation and rock drilling, whether using an integrated fast drill rod or a connecting sleeve, the connection thread between the drill rod tail and the drill rod is the place where the amplitude of the shock wave changes the most, that is, where the shock wave peak will be generated; The accuracy of thread machining, the matching degree of mutual cooperation, and even the deflection changes during the working process of the drill pipe have the greatest impact on this part, which is why drill pipe failures occur more often in this area. So, if drilling tool manufacturers can make efforts in this area, there is still a lot of work to be done.

But in reality, I believe that only improvement can be made. In a sense, this problem is unsolvable for horizontal excavation and rock drilling.

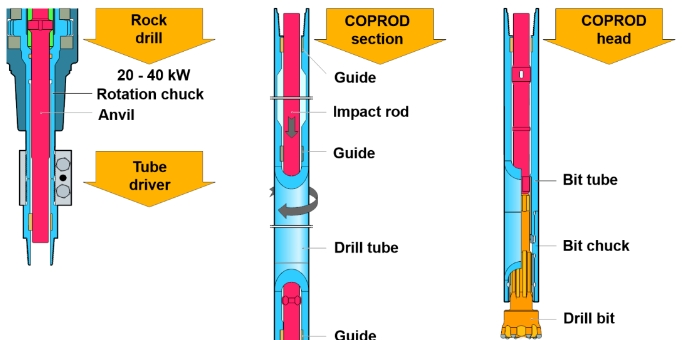

In open-pit rock drilling, down the hole hammers are now more commonly used, and since the drill pipe does not withstand impact, there is no such problem. Atlas skillfully used a kind of drill tool called COPROD for top hammer drilling. As shown in the figure, the outer casing does not bear impact, and the internal impact rod does not use threaded connection, but uses lap joint, so the diameter will not change, and the waveform will not have peak changes. The drilling speed and the life of the drilling tool are both very long, but basically it is only suitable for vertical drilling.