DTH Hammer Threaded Connection Tightening Issues and Solutions

During drilling operations, the threaded connections between the driver chuck and top sub may become excessively tightened due to high tension. While operators can initially attempt to disengage hammer threads directly on the rig, persistent thread locking or seizure requires the use of a dedicated **breakout bench** for controlled disassembly.

Modular Breakout Bench Features

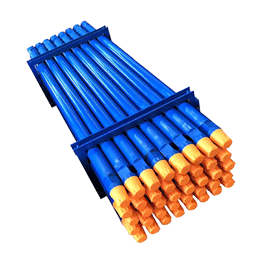

This compact yet high-power breakout bench is designed for portability and can be deployed in workshop or containerized environments. It supports disassembly of DTH hammers within a 3″–10″ diameter range Key considerations for equipment selection include:

1. Voltage compatibility

2. Power source type (electric/hydraulic)

Specification parameters

- DTH Hammer Size: 3” – 10”

- Bench Size: 1060*930*1050mm

- Weight: 800kg

- Max Tightening Torque: 67 kN*m(50ftlb)

- Max Loosening Torque: 81 kN*m(60ftlb)

- Operating Height: 800mm

- Hydraulic Pressure Range: 0-20 Mpa

- Power: 3Kw, 220V, 50Hz

- Chain Rotation Speed: less than 10 rpm

- Piston Driver Speed: 1.8m per minute

How to use DTH Hammer breakout bench equipment?

1.Put hammer on the bench.

2. Fix K-shaped base with nut.

Note: Please make sure red point on the K-shaped base and red point on the bolt are at the same side.

3.Adjust the position of hammer and wrench;

Use wrench to block the wrench flat of hammer;

Let wrench and jack in the same face.

4.Fix wrench.

5. Shake handle of Jack slowly till top sub away from hammer

6.After top sub dismantled, release pressure of Jack and put hammer on the bench like above photo to dismantle drive chuck of hammer.

7. Fix K-shaped base with nut.

Note: Please make sure red point on the K-shaped base and red point on the bolt are at the same side

8. Fix hammer

9. Adjust the position of hammer and wrench;

Use wrench to block the wrench flat of hammer;

Let wrench and jack in the same face.

10. Shake handle of Jack slowly till dive chuck away from hammer.